![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Tigercat Feller Buncher 845C, L845C Service Manual PDF

[2011/2016]Note: You may also be interested in the following PDF manual for Tigercat Feller Bunchers 845C, L845C:

Operator’s Manual

Any technique will never break or the user will break it. And in this case, it will get to the service engineer for repair. Here the engineer will be very welcome Service Manual - a manual for maintenance and repair.

This PDF Service Manual is intended for the current repair and service of the Tigercat Feller Bunchers 845C, L845C. These Tigercat Feller Bunchers are designed for harvesting trees, selective felling, thinning, and final felling applications in plantations and natural stands.

The service manual is detailed and shown in the figures - how to disassemble the equipment. Modern technology contains a microprocessor system or controller that signals ill health. Error messages may appear on the display of the unit.

The manual provides many drawings, illustrations, and diagrams that allow you to understand the logic of work and carry out repairs with the replacement of individual elements. The service manual describes how to fine-tune and configure the machine and its maintenance.

This service manual comes in PDF format. So, it doesn't require any installation (Instant Download). We recommend you use the application Adobe Acrobat Reader for working with PDF instructions. Also, we recommend you print this manual and use it as a handbook when it will be necessary.

For your convenience, we present you with a link 'Tigercat pdf manual instant preview' on the top of this page. This link will help you to preview this PDF manual and understand whether this manual contains needed for your service information or not.

Serial Numbers:

84511861 TO 84512500

84521861 TO 84522500

Models covered:

845C,

L845C.

CONTENTS:

- INTRODUCTION

- NON-APPROVED FIELD PRODUCT CHANGES

- SECTION 1 - SAFETY

- BATTERY DISCONNECT SWITCH

- BATTERY SAFETY

- CAB EXITS

- COOLING SYSTEM

- EMERGENCY CAB EXITS

- ENGINE DOORS

- ER BOOM SYSTEM PRECAUTIONS

- EXHAUST FUMES

- FELLING TREES

- FIRE PREVENTION

- FLUID INJECTION INJURY

- FLUID LEAKS

- GREASE INJECTION INJURY

- HAZARD ZONE

- HYDRAULIC PRESSURE HAZARD

- LIGHTNING SAFETY AWARENESS

- LOOSE CLOTHING HAZARD

- MACHINE STABILITY AND TRACTION

- NOISE LEVEL INSIDE THE CAB

- PARKING HAZARDS

- PROTECTIVE CLOTHING

- SAFETY INTERLOCK SWITCHES ON CAB DOORS

- SAFETY LABELS

- SAFETY PRECAUTIONS, GENERAL

- SAFETY PRECAUTIONS, OPERATING

- SAFETY PRECAUTIONS, SERVICING

- SAFETY SYMBOLS

- SIGNAL WORDS

- VIBRATION LEVELS INSIDE THE CAB

- WELDING, PRIOR TO

- WORKING WITH OIL

- SECTION 3 - LUBRICATION AND MAINTENANCE

- AIR CONDITIONING SYSTEM, CHECKING THE SYSTEM

- AIR INTAKE MAINTENANCE

- APPROVED HYDRAULIC OILS

- CASE DRAIN STRAINERS

- EMERGENCY EXITS, CHECK MONTHLY

- ENGINE AIR CLEANER

- ENGINE AIR CLEANER MAINTENANCE

- ER BOOM SYSTEM

- FILTERS

- FIRE PREVENTION

- FUEL TANK

- HYDRAULIC OILS, APPROVED

- HYDRAULIC TANK PRESSURIZATION INSTRUCTIONS

- LUBRICATION POINTS DIAGRAM, LEVELLER

- NEW MACHINE MAINTENANCE

- OIL SAMPLE COLLECTION PROCEDURES

- OIL SAMPLING PROGRAM

- PRESSURE AND SPEED SETTINGS

- PRESSURE SETTING PROCEDURES

- PREVENTIVE MAINTENANCE SCHEDULE

- SCHEDULED MAINTENANCE

- SWING DRIVE LUBRICATION

- TORQUE CHART

- TORQUE CHART, GENERAL

- TORQUE, FLUID CONNECTIONS

- TRACK OPERATION AND WEAR PREVENTION

- SECTION - 4 HYDRAULIC SYSTEM

- CASE DRAIN STRAINERS

- FILTERS, HYDRAULIC OIL STRAINER SERVICE NOTE

- HAND FILL PUMP, HYDRAULIC OIL

- HIGH-PRESSURE LIMITING CONTROL VALVE SET LOAD SENSE RELIEF VALVE

- HYDRAULIC OIL TANK

- HYDRAULIC PUMPS

- HYDRAULIC SYSTEM OPERATION

- LOAD SENSING

- MAIN CONTROL VALVE/MANIFOLD

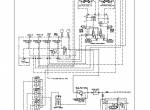

- SCHEMATIC DIAGRAMS

- SECTION 5 - PILOT SYSTEM

- ACCUMULATOR

- CHARGING

- CIRCUIT DESCRIPTION

- CIRCUIT DIAGRAM

- ELECTRICAL CIRCUIT

- PILOT SYSTEM COMPONENTS

- PILOT SYSTEM SCHEMATIC

- SECTION 6 - ELECTRICAL AND COMPUTERS

- ACCUMULATION MODE FEATURE

- ATTACHMENT ELECTRONIC ADJUSTMENT PROCEDURE

- CAB MODULE

- CHANNELS

- COMPUTER CONTROL SYSTEM (IQAN MDM DISPLAY)

- CURRENT OUT - TROUBLESHOOTING FOR OPEN CIRCUITS

- DISPLAY MODULE

- DOWNLOADING APPLICATIONS FROM THE DEALER WEBSITE

- ELECTRICAL INSTALLATION - CAB

- ELECTRICAL KIT - SERVICE AND DIAGNOSTICS

- ELECTRICAL SCHEMATICS

- ENGINE MODULE

- ERROR MESSAGES AND ALARMS

- FAULT CODES: ERROR MESSAGES

- GET APPLICATION

- GET ERROR/EVENT LOG

- ID-TAG

- IQAN

- Leveling ELECTRONIC ADJUSTMENT PROCEDURE

- MAIN SYSTEM ERRORS

- PDA REGISTRATION

- POWERVIEW DISPLAY MODULE

- SWITCH AND SENSOR LOCATIONS

- SYSTEM FUSES AND RELAYS

- UPDATE APPLICATION

- WARM-UP MODE

- WIRE COLOUR CODE CHART

- SECTION 7 - ENGINE START AND STOP

- COLD WEATHER STARTING

- ENGINE, RESTARTING AFTER ENGINE RUN OUT OF FUEL

- ENGINE, STOPPING

- SCHEMATIC DIAGRAM

- STARTING ENGINE

- STOPPING ENGINE

- SECTION 9 - ENGINE ANTI-STALL

- ANTI-STALL

- CIRCUIT DIAGRAMS

- ELECTRICAL CIRCUIT DIAGRAM

- SCHEMATIC DIAGRAMS

- SECTION 10 - OIL COOLER, RADIATOR, CHARGE AIR COOLER, AND FAN

- CHARGE AIR COOLER

- CIRCUIT DESCRIPTION

- FAN CIRCUIT DIAGRAM

- FAN CIRCUIT HYDRAULIC SCHEMATIC

- FAN DRIVE CONTROL VALVE

- FAN DRIVE ELECTRICAL SCHEMATIC

- FAN MOTOR

- FAN PUMP

- FAN SPEED CHECKS

- OIL COOLER

- RADIATOR

- RADIATOR COOLING SYSTEM

- SECTION 11 - TRACK DRIVE

- BEGIN OF REGULATION

- BRAKE CIRCUIT DESCRIPTION

- CIRCUIT DIAGRAM, DRIVE SYSTEM

- DRIVE MOTOR

- DRIVE MOTOR TYPE - IDENTIFICATION

- HYDRAULIC SYSTEM OPERATION

- IMPORTANT TRACK DRIVE NOTES

- LEFT TRACK SPEED ADJUSTMENT

- PRESSURE SETTINGS

- PRESSURE SETTINGS, DRIVE SYSTEM

- RIGHT-TRACK SPEED ADJUSTMENT

- SCHEMATIC DIAGRAMS

- SET STRAIGHT TRAVEL

- TRACK

- SECTION 12 - BOOM FUNCTIONS

- BOOM SYSTEM DESCRIPTION

- CIRCUIT DIAGRAM

- CONTROL VALVE

- CONVERTING

- 'ER' BOOM MANIFOLD CONNECTIONS

- 'ER' BOOM SYSTEM COMPONENTS

- 'ER' BOOM SYSTEM - SERVICE POSITION

- 'ER' BOOM SYSTEM - SERVICE SAFETY

- LOAD SENSING

- LOAD SENSING SYSTEM CIRCUIT DIAGRAM

- NON-'ER' BOOM MANIFOLD CONNECTIONS

- PRESSURE GAUGE CONNECTIONS

- PRESSURE SETTINGS, PORT RELIEF VALVES

- SECTION 13 - LEVELLING

- CHECKING PORT RELIEF VALVES

- CIRCUIT DESCRIPTION

- CIRCUIT DIAGRAM

- CIRCUIT HYDRAULIC SCHEMATIC

- CONTROL VALVE

- COUNTERBALANCE VALVE

- ELECTRICAL INSTALLATION (FACTORY INSTALLED) IQAN COMPUTER CONTROL SYSTEM

- ELECTRONIC ADJUSTMENT PROCEDURE, LEVELLING

- ENGINE ANTI-STALL/LOAD SENSING

- HYDRAULIC TANK PRESSURIZATION INSTRUCTIONS

- INSTALLING A VACUUM PUMP ON THE HYDRAULIC TANK

- Leveling CIRCUIT DESCRIPTION

- Leveling ELECTRONIC ADJUSTMENT PROCEDURE

- Leveling SYSTEM DESCRIPTION

- LUBRICATING CYLINDERS AND PINS

- REPLACING PORT RELIEFS

- SET COUNTERBALANCE VALVE PRESSURES

- UNDERCARRIAGE ASSEMBLY, LEVELLING

- SECTION 15 - SWING

- ADJUST OIL FLOW TO SWING MOTOR(SWING MOTOR SPEED)

- CIRCUIT DESCRIPTION

- CIRCUIT DIAGRAM

- CONTROL VALVE

- CROSSLINE RELIEF VALVES

- MAIN CONTROL VALVE

- PRESSURE SETTINGS

- SCHEMATIC DIAGRAMS

- SET SWING MOTOR SPEED

- SWING BEARING

- SWING DRIVE LUBRICATION

- SWING DRIVE VALVE PRIORITY CIRCUIT DESCRIPTION

- SWING VALVE SCHEMATIC

- SECTION 17 - SAW DRIVE

- CIRCUIT HYDRAULIC SCHEMATIC

- MOTOR BEGIN OF STROKE. SEE THE FELLING HEAD MANUAL MOTOR MINIMUM DISPLACEMENT. SEE FEELING HEAD MANUAL

- OPERATING DESCRIPTION

- PRESSURE SETTINGS

- SAW CIRCUIT DESCRIPTION

- SAW CONTROL VALVE

- SAW PUMP

- SECTION 18 - ACCUMULATOR, CLAMPS, WRIST, AND TILT

- ATTACHMENT CONTROL VALVE

- ATTACHMENT ELECTRONIC ADJUSTMENT PROCEDURE

- CIRCUIT DESCRIPTION

- CIRCUIT DIAGRAM

- CIRCUIT HYDRAULIC SCHEMATIC

- CLAMP ARMS CONTROL, JOYSTICK

- COMPUTER CONTROL SYSTEM (IQAN MDM DISPLAY)

- PRESSURE CHECKING

- SECTION 25 - MISCELLANEOUS

- DOOR CIRCUIT - ELECTRIC PUMP-OPERATED SYSTEM

- DOOR CIRCUIT - ENGINE OPERATED SYSTEM

- DOOR SWITCH

- ELECTRICAL SCHEMATIC

- ELECTRIC POWER ENGINE DOOR CIRCUIT SCHEMATIC

- ELECTRIC PUMP-OPERATED SYSTEM

- INSTRUMENT PANEL SWITCH

- POWER DOOR

Screenshots for Tigercat Feller Buncher 845C, L845C Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Tigercat Feller Buncher 845C, L845C Service Manual PDF:

Tigercat 7 09 T 2 F S015 B 15 K3 T U26A Installation, Operation and Maintenance Manual PDF

Electrical material includes step-by-step instructions, Product identification, technical data, installation section, operation information, detailed descriptions.

39$

[2006]

|

Tigercat 845 Feller Bunchers, 853 Machines, 860 Machines Installation and Maintenance Manual PDF

Factory file includes setting section, installation section, technical service, operation, information about safety, disassembly, detailed diagrams.

39$

[1994]

|

Tigercat240 Track Loader, 845 and 845B Feller Bunchers Installation and Maintenance Manual PDF

This Installation and Maintenance Manual contains all the technical information, installation section, maintenance, and repair presented in the format of PDF.

39$

[1997]

|

Tigercat L830 Leveller Feller Bunchers, 870, 870B Feller Bunchers Installation and Maintenance

The electronic guide covers detailed description, technical maintenance, repair, setting and troubleshooting information, lubrication, disessambly, and more.

39$

[1996]

|