![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Overview of the Tigercat 630B Service Manual

This comprehensive service manual for the Tigercat 630B Skidder (Issue 5.0, October 2003) contains 244 pages packed with crucial information for operating, maintaining, and troubleshooting your skidder. The content is fully searchable, with an indexed table of contents for quick navigation, making it a reliable tool for technicians and operators.

Contents

The service manual includes detailed information on:

- Introduction:

- S.A.E. standards

- Non-approved field product changes

- Section 1 - Safety:

- Articulation lock

- Battery disconnect switch

- Cab safety cable

- Cab support brace

- Cooling system

- Exhaust fumes

- Fire prevention

- First aid

- Fluid leaks

- Hydraulic pressure hazard

- Loose clothing hazard

- Parking the machine

- Protective clothing

- Safety precautions (general, operating, servicing)

- Safety symbols

- Signal words

- Section 3 - Lubrication & Maintenance:

- Air cleaner maintenance

- Air conditioning system, checking

- Approved hydraulic oils

- Center joint

- Emergency exits, check monthly

- Filters

- Fire prevention

- General maintenance

- Grapple snubber maintenance

- Hour meter maintenance

- Lubrication and service points

- New machine maintenance

- Oil lost from leakage

- Pressurized water system maintenance

- Replacing the engine serpentine belt

- Scheduled maintenance

- Service and lubrication points

- Speed control lever adjustment

- Startup procedure after major maintenance

- Tilting the cab

- Torque chart

- Torque chart, general

- Wheels, installing

- Winch lubrication - Lantec only

- Winch lubrication - Lufkin only

- Section 5 - Pilot System:

- Charge pressure filter

- Charge pump

- Circuit description (6301001 to 6301217)

- Circuit description (6301218 to 6301999)

- Circuit diagram (6301001 to 6301217)

- Circuit diagram (6301218 to 6301999)

- Pilot manifold

- Pressure settings

- Section 6 - Electrical, Gauges, and Alarms:

- Fan controller relay assembly

- Fuse and relay panel

- Gauges and alarms

- Schematic diagram (6301001 to 6301020)

- Schematic diagram (6301021 to 6301350)

- Schematic diagram (6301351 to 6301999)

- Sensor details

- Switch and sensor locations

- Troubleshooting and testing

- Wire color code chart

- Section 7 - Engine Start and Stop:

- Drive prevent valve

- Fuel control valve

- Main pump unloading valve

- Start circuit description

- Start circuit diagram

- Start motor and solenoid

- Start solenoid relay

- Tachometer setup

- Section 8 - Drive:

- Axles

- Circuit description

- Drive system

- Hydraulic oil heating procedure

- Test drive - Rexroth pump and Rexroth motors

- Test drive - Sauer pump and Rexroth motors

- Transmission

- Transmission identification

- Wheel installation

- Section 9 - Brakes:

- Accumulator

- Brakes

- Charging valve, accumulator

- Circuit diagram

- Differential locks

- Main pump

- Multifunction valve

- Parking brake

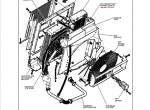

- Section 10 - Oil Cooler/Radiator and Cross-Flow Fan:

- Cross-flow fan - FDC (6301351 to 6301999)

- Cross-flow fan - Lever operated (6301001 to 630135)

- Oil cooler

- Oil cooler and radiator installation

- Oil cooler circuit description

- Oil cooler circuit diagram

- Section 11 - Steering and Center Joint:

- Center joint

- Identifying earlier and later bearings

- Priority valve

- Steer control valve

- Steering

- Testing the steering operation

- Section 12 - Grapple, Arch, and Boom:

- Circuit description

- Circuit diagrams

- Grapple control valve

- Grapple snubber maintenance (See Section 3)

- Joystick control valve (arch and grapple)

- Port relief valve description (grapple valve)

- Pressure settings

- Relief valves

- Snubber maintenance - grapple (See Section 3)

- Section 13 - Winch:

- Control lever valve

- Grapple control valve

- Lantec winch

- Lufkin winch

- Pressure settings

- Section 14 - Dozer Blade:

- Circuit description

- Circuit diagram

- Control lever pilot valve

- Dozer control valve

- Pressure settings

Why Choose This Manual?

With a focus on safety and precise diagnostics, this manual provides detailed troubleshooting guidelines, maintenance charts, and step-by-step procedures, which set it apart from other standard repair manuals. Unlike many competitors, this manual also includes electrical system schematics and circuit diagrams for easier navigation and repairs.

Features of the Tigercat 630B Service Manual

- Fully Searchable PDF: Quickly locate specific sections or procedures.

- Detailed Maintenance Schedules: Easy-to-follow guidelines for maintenance tasks to extend the lifespan of your skidder.

- Extensive Schematics: Comprehensive wiring diagrams for gauges, alarms, and major system circuits, tailored for different serial number ranges.

- Expert Tips: Written by industry professionals, this manual ensures you're equipped with expert knowledge on servicing and troubleshooting.

Download and Use Guidelines

This Tigercat 630B Skidder service manual is available as an instant download in PDF format. Upon purchase, you'll receive a secure link to access the manual, with instructions on saving it for offline use. It’s a must-have resource for technicians, heavy equipment operators, and service centers that handle Tigercat skidders.

About Tigercat 630B Skidder

The Tigercat 630B is a rugged and reliable skidder designed for forestry operations. Its powerful drive system, coupled with precise steering and hydraulic systems, ensures productivity in the most demanding environments. This manual serves as the definitive guide to maintaining the skidder's efficiency and handling repairs effectively.

FAQs

How do I use the Tigercat 630B Skidder manual?

The manual is structured for easy navigation, featuring indexed sections on safety, maintenance, and diagnostics. You can quickly search by keyword or browse the table of contents to find relevant information.

What formats are available?

The Tigercat 630B Skidder manual is provided in PDF format, which you can view on any device that supports PDF readers.

Is this manual suitable for technicians?

Absolutely! This manual is designed for both operators and technicians, with in-depth service, maintenance, and troubleshooting procedures for effective and safe machine operation.