![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Sany Crawler Hydraulic Excavator SY215CLC Shop Manual PDF

[]This PDF Shop Manual has been prepared to provide information regarding repair procedures for the Sany Crawler Hydraulic Excavator SY215CLC Model. This manual allows you to find the necessary shop information for the user, and print out individual pages or the entire text as a whole.

Models covered:

SY215CLC

Documentation No.: ZJSYF0301EN(03-12)-SY215CLC

Contents:

- 1 Introduction

- 1.1 Safety Notice

- 1.2 How to Read the Shop Manual

- 1.3 Terms for Maintenance Standard

- 1.4 Handling Electrical and Hydraulic Components

- 1.5 Hose Connector

- 1.6 Table of Standard Tightening Torques

- 1.7 Type of Bolts

- 1.8 Tightening Sequence

- 1.9 Maintenance of Half Flanges

- 1.10 Conversion Table

- 2 Shop Safety

- 2.1 Hazard Alert Information

- 2.2 General Shop Safety

- 3 Specifications

- 3.1 Dimensions

- 3.2 Working Ranges

- 3.3 Technical Specifications

- 3.4 Weight Table

- 3.5 Fuel and Coolant

- 3.6 Engine Performance Curve

- 4 Structure and Function

- 4.1 Engine and Cooling System

- 4.2 Power Train

- 4.3 Undercarriage and Frame

- 4.4 Hydraulic System, Part 1

- 4.5 Hydraulic System, Part 2

- 4.6 Hydraulic System, Part 3

- 4.7 Air Conditioning System

- 4.8 Engine Control

- 4.9 Electrical Control System

- 4.10 Monitoring System

- 5 Standard Values

- 5.1 Standard Values for Chassis-related Parts

- 6 Testing and Adjusting

- 6.1 Engine Speed - Test and Calibrate

- 6.2 Exhaust Gas Color - Test

- 6.3 Engine Speed Sensor - Adjust

- 6.4 A/C Compressor Belt Tension - Test and Adjust

- 6.5 Swing Bearing Clearance - Measure

- 6.6 Track Tension - Test and Adjust

- 6.7 Hydraulic Pressure in Hydraulic Circuits - Test and Adjust

- 6.8 Control Circuit Oil Pressure - Test and Adjust

- 6.9 Solenoid Valve Output Pressure - Measure

- 6.10 Pilot Valve Output Pressure - Measure

- 6.11 Pilot Valves (Work Equipment and Swing) - Adjust

- 6.12 Work Equipment Hydraulic Drift - Test

- 6.13 Residual Pressure in Hydraulic Circuit - Release

- 6.14 Oil Leakage - Measure

- 6.15 Air in Each Component - Bleed

- 7 Troubleshooting

- 7.1 Points to Remember When Troubleshooting

- 7.2 Sequence of Events in Troubleshooting

- 7.3 Troubleshooting Procedures

- 7.4 Connectors

- 7.5 Failure Symptoms and Service Codes

- 8 Disassembly and Assembly

- 8.1 Reading Guide

- 8.2 Operating Precautions

- 8.3 Radiator AS - Remove and Install

- 8.4 Engine and Hydraulic Pump AS - Remove and Install

- 8.5 Final Drive AS - Remove and Install

- 8.6 Final Drive AS - Disassemble and Assemble

- 8.7 Swing Motor and Swing Drive AS - Remove and Install

- 8.8 Swing Motor and Swing Drive AS - Disassemble and Assemble

- 8.9 Idler AS - Disassemble and Assemble

- 8.10 Sprocket - Remove and Install

- 8.11 Track AS - Remove and Install

- 8.12 Swing Bearing AS - Remove and Install

- 8.13 Swing Platform AS - Remove and Install

- 8.14 Swivel Joint AS - Remove and Install

- 8.15 Swivel Joint AS - Disassemble and Assemble

- 8.16 Hydraulic Tank AS - Remove and Install

- 8.17 Control Valve AS - Remove and Install

- 8.18 Hydraulic Pump AS - Remove and Install

- 8.19 Middle Oil Seal (Hydraulic Pump Input Shaft)- Remove and Install

- 8.20 Pilot Valve AS (Work Equipment) - Disassemble and Assemble

- 8.21 Pilot Valve AS (Travel) - Disassemble and Assemble

- 8.22 Hydraulic Cylinder AS - Disassemble and Assemble

- 8.23 Work Equipment AS - Remove and Install

- 8.24 Air Conditioner AS - Remove and Install

- 8.25 Counterweight AS - Remove and Install

- 8.26 Cab AS - Remove and Install

- 8.27 Cab Window Glass – Disassemble and Assemble

- 8.28 Front Window AS - Disassemble and Assemble

- 8.29 Monitor - Remove and Install

- 8.30 Controller AS - Remove and Install

- 8.31 Radio

- 8.32 Battery

- 8.33 Start Switch

- 8.34 Fuse Box

- 8.35 Wiper

- 8.36 Relay

- 8.37 Sensor

- 8.38 Connector Terminals - Insert and Remove

- 9 System Schematics

- 9.1 Hydraulic System Diagram

- 9.2 Air-Conditioning Electrical Diagram

- 9.3 Fuse Box Relay

- 9.4 Control Switches and Monitor Electrical Diagram

- 9.5 Operator Cab Electrical Diagram

- 9.6 Chassis Electrical Diagram

Please, read and follow the instructions, rules, and notes to avoid any problems such as breakdowns, damage, and injuries. This is the best online file, both for experienced craftsmen and for beginners, as prepared by experts in this field.

Features of the Manual

Format: PDF

Language: English

Compatible with all versions of Windows, Mac, Linux, iPhone, iPad, and Android

This electronic guide is a system of care in the service and maintenance of Sany Crawler Hydraulic Excavators, which allows for the detection and elimination of problems and inaccuracies. You can study this PDF manual using screenshots and a list of content, which is presented in the manual description.

FAQs

How do I download the manual?

It is easy to purchase this product. Just click on the 'Buy Now' button and follow the instructions. After payment, you will get the link for downloading your PDF Sany Manual. So, after a few minutes, you will get your guide and you can start studying it.

Is the manual printable?

Yes, all pages can be printed easily.

Still have questions?

For any question or remark, or in case of any error in the contents of this guide, please contact our managers.

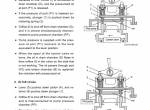

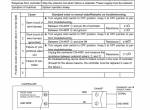

Screenshots for Sany Crawler Hydraulic Excavator SY215CLC Shop Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Sany Crawler Hydraulic Excavator SY215CLC Shop Manual PDF:

Sany Wheel Loader SW075, SW085 Operation and Maintenance Manual PDF

The factory file includes safety rules, operation instructions, maintenance information, specifications, troubleshooting, many different tables.

39$

[]

|

Sany SY500C1I3KH Hydraulic Excavаtor body Parts Catalog PDF

The factory file consists of sections about technical data, accessories, fittings, electrical system assembly, diagrams, parts instructions.

39$

[]

|

Sany Tracked Hydraulic Excavator SY485H Service Manual PDF

The factory file consists of sections about descriptions, technical data, specifications, hydraulic and electrical diagrams.

39$

[2016]

|

Sany Engline Catalog Number SY485C1I3KHE01 Parts Manual PDF

The factory file covers sections about engine information, settings, a list of parts, many illustrations with descriptions, diagrams, schemes, and tables.

39$

[]

|