![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Perkins Engines 1200E Series Electrical And Electronic A&I Guide PDF

[11/2011]This manual is intended to provide the information necessary for correct electrical and electronic installation of Perkins 1204E or 1206E Industrial Engines, into an off-highway machine.

The information contained in this document is the best available at the time of authoring and describes the application and installation requirements for a production representative engine and software configuration.

This electrical guide comes in PDF format. We recommend using Adobe PDF Reader, to be sure all images/graphics will display correctly. If necessary, you can print the entire document or selected partitions.

Publication number:

TPD1725E1

Models covered:

1204E-E44TA

1204E-E44TTA

1206E-E66TA

1206E-E70TTA

Four and Six cylinder diesel engines for agricultural, industrial, construction applications

Models: BK, BL, MK, and ML

CONTENTS:

- 1.0 INTRODUCTION AND PURPOSE

- 1.1 APPLICABLE ENGINES

- 1.2 ELECTRONIC APPLICATIONS CONTACTS

- 1.3 SAFETY

- 2.0 ENGINE & AFTERTREATMENT COMPONENT OVERVIEW

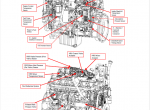

- 2.1 MAIN ENGINE SENSOR AND ACTUATOR DETAILS

- 2.2 AFTERTREATMENT SYSTEM SENSOR & ACTUATOR DETAILS

- 2.3 SYSTEM COMPONENT DIAGRAMS AND SCHEMATICS

- 2.4 ENGINE & AFTERTREATMENT COMPONENT LAYOUT DIAGRAMS

- 3.0 CUSTOMER SYSTEM OVERVIEW KEY ELEMENTS

- 3.1 AFTERTREATMENT CONNECTIONS

- 3.2 CONNECTION, POWER AND GROUNDING

- 3.3 INDICATION, STARTING AND STOPPING THE ENGINE

- 3.4 CONTROLLING THE ENGINE

- 3.5 AFTERTREATMENT OPERATION AND REGENERATION

- 3.8 OPTIONAL CUSTOMER INSTALLED COMPONENTS

- 3.9 TYPICAL CUSTOMER INSTALLED COMPONENT DIAGRAM

- 4.0 POWER AND GROUNDING CONSIDERATIONS

- 4.1 ENGINE BLOCK GROUNDING

- 4.2 VOLTAGE AND CURRENT REQUIREMENTS

- 4.3 ECM POWER SUPPLY CIRCUIT RESISTANCE

- 4.4 ENGINE ECM POWER SUPPLY CIRCUIT RESISTANCE TEST

- 4.5 DIRECT BATTERY CONNECTION REQUIREMENTS

- 4.6 POWERING THE ENGINE ECM VIA AUXILIARY POWER SUPPLIES

- 4.7 SENSOR COMMON CONNECTIONS

- 4.8 MANDATORY FUEL LIFT PUMP INSTALLATION

- 5.0 CONNECTORS AND WIRING HARNESS REQUIREMENTS

- 5.1 ENGINE ECM J1 CONNECTOR

- 5.2 ENGINE WITH AFTERTREATMENT CONNECTORS 1206E-E70TTA ONLY

- 5.3 DIAGNOSTIC CONNECTOR

- 5.4 CONNECTOR TERMINAL CONTACTS

- 5.5 HARNESS WIRING STANDARDS

- 6.0 CONNECTING TO ENGINE AFTERTREATMENT

- 6.1 1204E AND 1206E EMISSION CRITICAL AFTERTREATMENT INSTALLATION

- 6.2 1206E-E70TTA EMISSION CRITICAL AFTERTREATMENT

- 6.4 AUXILIARY SENSOR INSTALLATION AND CONNECTION

- 7.0 STARTING AND STOPPING THE ENGINE

- 7.1 STARTING THE ENGINE

- 7.2 STOPPING THE ENGINE (AND PREVENTING RESTART)

- 8.0 MACHINE FAN CONTROL

- 8.1 HYDRAULIC FAN CONTROL OPERATION

- 9.0 ENGINE SPEED DEMAND

- 9.1 ANALOGUE SENSOR

- 9.2 PWM SENSOR - COMPATIBILITY

- 9.3 THROTTLE LOCK (PTO MODE)

- 9.4 MULTI POSITION THROTTLE SWITCH (MPTS)

- 9.5 TORQUE SPEED CONTROL TSC1 (SPEED CONTROL OVER CAN)

- 9.6 ARBITRATION OF SPEED DEMAND

- 9.7 ACCELERATION AND DECELERATION RAMP RATES

- 9.8 THROTTLE BEHAVIOR DURING ENGINE GOVERNOR CHANGES

- 9.10 DEFINITION OF ENGINE SPEED POINTS

- 10.0 COLD WEATHER ENGINE OPERATION & STARTING AIDS

- 10.1 CONTROL OF GLOW PLUGS BY THE ENGINE ECM

- 10.2 ETHER COLD START SYSTEMS

- 10.3 COLD WEATHER REGENERATION AID

- 10.4 HEATED BREATHER

- 11.0 ENGINE & AFTERTREATMENT MONITORING – HIGH-LEVEL INDICATORS & OPERATOR DISPLAYS

- 11.1 ENGINE MANAGEMENT SYSTEM STATUS INDICATION

- 11.2 GAUGE DRIVERS

- 11.3 LAMP OUTPUTS

- 11.4 ACTIVATION OF J1939 INDICATORS

- 12.0 ENGINE AND AFTERTREATMENT MONITORING SYSTEM

- 12.1 GENERAL INFORMATION

- 12.2 ENGINE MONITORING & PROTECTION

- 12.3 AFTERTREATMENT MONITORING & PROTECTION

- 13.0 MONITORED INPUTS FOR CUSTOMER FITTED SENSORS

- 13.1 AIR FILTER SERVICE INDICATOR – AIR INTAKE RESTRICTION SWITCH

- 13.2 COOLANT LEVEL SWITCH

- 13.3 WATER IN FUEL TRAP SWITCH

- 13.4 AUXILIARY TEMPERATURE SENSOR

- 13.5 AUXILIARY PRESSURE SENSOR

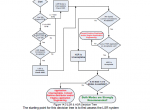

- 14.0 REGENERATION SYSTEM & CUSTOMER INTERFACE

- 14.1 LOW TEMPERATURE REGENERATION SYSTEM OPERATION

- 14.2 LOW TEMPERATURE REGENERATION OPERATOR INTERFACE

- 14.3 LOW TEMPERATURE REGENERATION SYSTEM OPERATION EXAMPLE

- 14.4 HIGH TEMPERATURE DPF REGENERATION SYSTEM OPERATION

- 14.5 TOTAL REGENERATION SYSTEM OPERATION EXAMPLE

- 14.6 HIGH TEMPERATURE REGENERATION SYSTEM OPERATOR DISPLAY

- 14.7 INITIAL INSTALLATION REQUIREMENTS

- 15.0 ENGINE GOVERNOR

- 15.1 MIN/MAX GOVERNING

- 15.2 ALL SPEED

- 15.3 AUXILIARY GOVERNOR

- 15.4 RATING SELECTION VIA SERVICE TOOL

- 15.5 ENGINE HIGH-SPEED GOVERNOR (GOVERNOR RUN-OUT)

- 15.6 MODE SELECTION

- 16.0 TIER 4 INTERIM SERVICE TOOL FEATURES

- 16.1 INTRODUCTION

- 16.2 SERVICE TOOL FEATURES FOR A 1206E-E70TTA

- 16.3 SERVICE TOOL FEATURES FOR A 1204E &1206E

- 17.0 DATALINK SUPPORT

- 17.1 SAE J1939

- 17.2 CONNECTION AND USE OF THE J1939 CAN BUS

- 18.0 J1939 SUPPORTED PARAMETERS QUICK REFERENCE

- 19.0 J1939 PARAMETERS – DETAILED DESCRIPTIONS

- 19.1 SENDING MESSAGES TO THE ENGINE ECM

- 19.2 J1939 SECTION 71 – TSC1 OPERATION

- 19.3 J1939 ENGINE ECM TRANSMIT PGN SUPPORT

- 19.4 J1939 ENGINE ECM RECEIVE PGN SUPPORT

- 19.5 J1939 SECTION 73 - DIAGNOSTIC LAYER

- 19.6 SUPPORTED PARAMETERS – SECTION 21 - SIMPLIFIED DESCRIPTIONS

- 19.7 SUPPORTED PARAMETERS – SECTION 81 NETWORK MANAGEMENT - DETAILED DESCRIPTIONS

- 20.0 APPENDICES

- 20.1 APPENDIX 1 - ECM J1 CONNECTOR TERMINAL ASSIGNMENTS

- 20.2 APPENDIX 2 – ECM J2 TERMINAL ASSIGNMENT

- 20.3 APPENDIX 3 - ELECTRONIC OPTIONS SELECTION FORM

- 20.4 APPENDIX 4 – LIST OF DIAGNOSTIC AND EVENT CODES

- 20.5 APPENDIX 5 – DOCUMENT CHANGE TRACKER

Screenshots for Perkins Engines 1200E Series Electrical And Electronic A&I Guide PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.