![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Perkins 1200F Series Electronic Application And Installation Manual PDF

[12/2014]This application and installation manual contains general safety information, engine data, description of maintenance and repair procedures, technical specifications for Perkins Engine 1200F Series.

This manual includes lots of illustrations, pictures, parts diagrams, schematics that help to install or remove some details and components of Perkins Engine.

This manual has been compiled to explain mandatory requirements, provide information for designers, and provide information on the application and installation of the 1204F-1206F engines into industrial equipment.

This workshop guide is presented in PDF format, includes 256 pages. Workshop manual works after installing Adobe PDF Reader, which allows you to print out individual pages or the entire text as a whole.

Models: MT, MU, MV, MW, BM, and BN

Perkins 1200F Series:

1204F-E44TA

1204F-E44TTA

1206F-E70TA

1206F-E70TTA

Four & six cylinder diesel engines for agricultural, industrial, construction applications

CONTENTS:

- 1.0 SAFETY

- 1.1 WARNING – WELDING

- 2.0 ENGINE & AFTERTREATMENT COMPONENT OVERVIEW

- 2.1 MAIN ENGINE SENSOR AND ACTUATOR DETAIL

- 2.2 AFTERTREATMENT SYSTEM SENSOR & ACTUATOR DETAILS

- 2.3 SYSTEM COMPONENT DIAGRAMS & SCHEMATICS

- 2.4 ENGINE & AFTERTREATMENT COMPONENT LAYOUT DIAGRAMS

- 3.0 CUSTOMER SYSTEM OVERVIEW KEY ELEMENTS

- 3.1 AFTERTREATMENT CONFIGURATIONS

- 3.2 TIER 4F MANDATORY INSTALL COMPONENTS

- 3.3 OPTIONAL CUSTOMER INSTALLED COMPONENTS

- 4.0 POWER & GROUNDING CONSIDERATIONS

- 4.1 SYSTEM GROUNDING

- 4.2 SYSTEM VOLTAGE & CURRENT REQUIREMENTS

- 4.3 ECM POWER SUPPLY & CIRCUIT RESISTANCE

- 4.4 ENGINE ECM POWER SUPPLY CIRCUIT RESISTANCE TEST

- 4.5 DEF SYSTEM POWER SUPPLY

- 4.6 SUPPRESSION OF VOLTAGE TRANSIENTS

- 4.7 DIRECT BATTERY CONNECTION REQUIREMENTS

- 4.8 POWERING THE ENGINE ECM VIA AUXILIARY POWER SUPPLIES

- 4.9 SENSOR COMMON CONNECTIONS

- 5.0 CONNECTORS & WIRING HARNESS REQUIREMENTS

- 5.1 ENGINE ECM J1 CONNECTOR

- 5.2 ENGINE ECM J1 CONNECTOR I/O

- 5.3 ECM CONNECTOR ASSEMBLY & DISASSEMBLY

- 5.4 DIAGNOSTIC CONNECTOR

- 5.5 MANDATORY ENGINE & AFTERTREATMENT CONNECTORS

- 5.6 CONNECTOR TERMINAL CONTACTS

- 5.7 WIRE SPECIFICATION REQUIREMENTS

- 5.8 HARNESS WIRING STANDARDS

- 6.0 CUSTOMER CONNECTION OF ENGINE COMPONENTS

- 6.1 WATER IN FUEL SWITCH

- 6.2 AMBIENT AIR TEMPERATURE SENSOR

- 6.3 ENGINE ELECTRICAL FUEL LIFT PUMP

- 7.0 1204F CONNECTING TO THE ENGINE AFTERTREATMENT

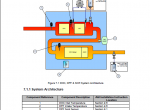

- 7.1 DOC + DPF + SCR

- 7.2 DOC + SCR

- 7.3 1204F DEF SYSTEM

- 7.4 1204F AFTERTREATMENT WIRING SCHEMATICS

- 8.0 1206F CONNECTING TO THE ENGINE AFTERTREATMENT

- 8.1 IG CEM

- 8.2 1206F PUMP ELECTRONICS & TANK UNIT (PETU)

- 8.3 1206F AFTERTREATMENT WIRING SCHEMATIC

- 9.0 COMPONENT INSTALLATION REQUIREMENTS

- 9.1 DPF SOOT SENSOR

- 9.2 NOX SENSOR

- 9.3 AMMONIA (NH3)SENSOR

- 9.4 DPF IN AND SCR PERKINSIN COMBINED TEMP SENSOR (1206F)

- 9.5 IG CEM ID MODULE

- 9.6 DOC, DPF & SCR INLET TEMPERATURE SENSORS (1204F)

- 10.0 STARTING AND STOPPING THE ENGINE

- 10.1 STARTING THE ENGINE

- 10.2 STOPPING THE ENGINE (AND PREVENTING RESTART)

- 11.0 ENGINE SPEED DEMAND

- 11.1 ANALOGUE SENSOR

- 11.2 PWM SENSOR - COMPATIBILITY

- 11.3 THROTTLE LOCK (PTO MODE)

- 11.4 MULTI POSITION THROTTLE SWITCH (MPTS)

- 11.5 TORQUE SPEED CONTROL TSC1 (SPEED CONTROL OVER CAN)

- 11.6 ARBITRATION OF SPEED DEMAND

- 11.7 ACCELERATION AND DECELERATION RAMP RATES

- 11.8 THROTTLE BEHAVIOUR DURING ENGINE GOVERNOR CHANGES

- 11.9 ENGINE LIMP HOME SPEED

- 11.10 THROTTLE CALIBRATION

- 11.11 DEFINITION OF ENGINE SPEED POINTS

- 12.0 COLD WEATHER ENGINE OPERATION & STARTING AIDS

- 12.1 CONTROL OF GLOW PLUGS BY THE ENGINE ECM

- 12.2 ETHER COLD START SYSTEMS

- 12.3 HEATED BREATHER

- 12.4 COLD WEATHER REGENERATION AID

- 12.5 EXTREME LOW TEMPERATURE AFTERTREATMENT AMBIENT AIR TEMPERATURE SENSOR

- 12.6 ENGINE SOFT START PROTECTION

- 13.0 OPERATOR INDICATORS & FAULT DISPLAYS

- 13.1 ENGINE & AT DIAGNOSTIC SYSTEMS

- 13.2 GAUGE DRIVERS

- 13.3 LAMP OUTPUTS & OPERATION

- 14.0 ENGINE & AFTERTREATMENT MONITORING SYSTEM

- 14.1 GENERAL INFORMATION

- 14.2 NON EMISSIONS CRITICAL COMPONENT MONITORING & PROTECTION

- 14.3 EMISSIONS CRITICAL COMPONENTS MONITORING & PROTECTION

- 15.0 MONITORED INPUTS FOR CUSTOMER FITTED SENSORS

- 15.1 AIR FILTER SERVICE INDICATOR – AIR INTAKE RESTRICTION SWITCH

- 15.2 COOLANT LEVEL SWITCH

- 15.3 AUXILIARY TEMPERATURE SENSOR

- 15.5 AUXILIARY PRESSURE SENSOR

- 16.0 AFTERTREATMENT SYSTEM MACHINE INTEGRATION

- 16.1 AFTERTREATMENT SYSTEM OPERATION

- 16.2 LOW TEMPERATURE AFTERTREATMENT REGENERATION SYSTEM

- 16.2 DEF SYSTEM OPERATION

- 16.3 DEF SYSTEM MACHINE INTERFACE REQUIREMENTS

- 17.0 ENGINE GOVERNOR

- 17.1 MIN / MAX GOVERNING

- 17.2 ENGINE ALL SPEED GOVERNING

- 17.3 RATING SELECTION USING EST

- 17.4 ENGINE HIGH SPEED GOVERNOR (GOVERNOR RUN-OUT)

- 17.5 MODE SELECTION

- 18.0 DATALINK SUPPORT

- 18.1 SAE J1939

- 18.2 CONNECTION AND USE OF THE J1939 CAN BUS

- 19.0 J1939 SUPPORTED PARAMETERS QUICK REFERENCE

- 20.0 J1939 PARAMETERS – DETAILED DESCRIPTIONS

- 20.1 SENDING MESSAGES TO THE ENGINE ECM

- 20.2 J1939 SECTION 71 – TSC1 OPERATION

- APPENDIX

- APPENDIX 1 COMPLETE SYSTEM CONNECTOR LISTS

Screenshots for Perkins 1200F Series Electronic Application And Installation Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.