![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

New Holland Telehandler LM5030 PDF Set of Manuals

[10/2011]Specifically engineered to provide small to medium sized livestock or mixed farming enterprises with a cost-effective materials handling solution, these robust, easy-to-use, new generation New Holland telehandler LM5030 benefit from the latest technology and the support of the best dealer network, to ensure maximum productivity. The new LM5030 telehandler meets your needs for a compact, stable, low profile machine capable of tackling the largest jobs in the tightest of spaces.

Workshop manuals are designed specifically for the New Holland Telehandler. Here you will find information about components, maintenance, and repair of the New Holland telehandlers LM5030 and their systems.

This set of workshop manuals contains technical information, detailed schemes, and diagrams, tables, and illustrations, through which you can visually inspect a piece of equipment. This guide helps beginners and experienced professionals.

New Holland manuals are present in English in PDF format so you can find the information you need and print all the text or individual pages. For convenience, we recommend using Adobe PDF Reader to ensure the correct display of all graphics.

Models:

LM5030

Table of Contents:

- 1. Engine

- Main engine specifications

- Engine model views

- Removal and installation of engine and radiator

- Removal

- Installation

- Filling the engine cooling system

- Bleeding air from the system

- Important warnings

- 2. Transmission

- Variable displacement motor

- Exchanging the shaft seal

- Exchanging seals

- Exchanging the controller

- Sealing the cover

- Checking

- Checking behind of regulation control EP

- Checking beginn of regulation control HD

- Checking beginn of regulation control HA

- Checking beginn of regulation control DA1/4, DA2, 3, 4, 5, 6

- Variable displacement pump

- Sealing of the drive shaft

- Sealing of the boost pump

- Sealing of the control piston cover

- Sealing of the valves

- Sealing of the pressure cut--off valve

- Sealing of the control valve

- Removal of the control module

- Control modules

- Pump disassembly

- Removal of the rotary group

- Disassembly of the positioning piston

- Inspection notes

- Inspection of the rotary group parts

- Installation of the rotary group

- Installation of the rotary group DA

- Assembly of the pump DA

- Installation of the rotary group EP, HD, HW

- Assembly of the pump EP, HD, HW

- Assembly of the pump

- Transmission 2 speed

- Diagrams of the reduction unit and exploded views

- Disassembly of the integrated reduction gear

- Assembly of the integrated reduction gear

- Special tools

- 3. Front Axle

- Wheel toe - in check

- Component overhaul

- The front axle removal procedure

- Installation

- Planetary reduction 1:6 and the steering case

- Steering cylinder

- Differential: Normal preloader differential unit

- Flanger reduction gear 603 types: Integral 603 Input gear

- Bevel Pinon: Version normal flange and nut revolution counter ver

- Ring and pinion adjusting: the step for step preloaded differential

- Swinging support

- Planetary reduction: 1:4,23

- Differential: preloaded limited slip differential unit

- Differential: with the block to spheres 100%

- Differential: normal differential

- Differential: limited slip differential unit (45%)

- Update limited slip differential

- Update differential with service, negative and 100% lock brake

- Bevel pinion: flanged to reduction gear 603

- Ring and pinion adjusting: version pinion cover and single arm

- Ring and pinion adjusting: version pinion integral and double arm

- Drive shaft removal

- Special tools

- 4. Rear Axle

- Drive shaft removal

- Reattachment

- Rear axle removal procedure

- Overhaul

- Installation

- 5. Brakes

- Disassembly the incoming disc brake

- Assembly the incoming disc brake

- Disassembly brake: service brake and mechanic parking brake

- Assembly brake: service brake and mechanic parking brake

- Disassembly brake: service brake and differential hydraulic lock 100%

- Assembly brake: service brake and differential hydraulic lock 100%

- Disassembly brake: service brake, negative brake, 100% locked

- Assembly brake: service brake, negative brake, 100% locked

- Disassembly brake: negative brake 4 CUP springs

- Assembly brake: negative brake 4 CUP springs

- 6. Hydraulic System

- Hydraulic system circuit

- Hydraulic control valve

- Cylinders

- Lifting cylinders dismounting instructions

- Boom overhaul

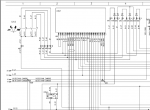

- 7. Electrical System

- General description

- Setting codes definition

- Engine version setting

- Functions

- Signal and/or alarm indicator lights

- Emergency led L6

- Indicator lights L11 and L12

- Breaks failure L22 led

- Hydraulic oil temperature L23 led

- Instruments indicators

- (S5) Yanmar engine cooling liquid temperature indicator set 1

- (S5) Perkins engine cooling liquid temperature indicator set 3

- (S4) Yanmar engine fuel level indicator set 1

- (S4) Perkins engine fuel level indicator set 3

- (S1) Analogical rev. Counter

- LCD display

- Hour meter

- Clock

- PTO number of revs

- Speedometer

- Programming of K for the speedometer

- Hodograph

- Gear engaged

- Service

- Inputs

- Digital Inputs

- Analogical Inputs

- SAR--ANTI--TIPPING SYSTEM (Control Panel)

- Warnings

- Electrical connections

- System layout

- Control panel

- Panel Test

- Operation

- Operative Mode

- Panel

- System Configuration

- Telehandler layout in machine calibration

- Telehandler layout in tools calibration

- Calibration mode

- Enter calibration mode

- Machine calibration

- Calibration modes

- Calibration steps

- Mode 1

- Tools calibration

- Calibration modes

- Calibration steps

- Reset calibration

- Exit calibration mode

- Test mode

- Panel

- Step

- Alarms

- Panel

- Alarm code

- Alarm code list

- Alarms/faults/error system

- Alarms/faults/error machine

- Warnings

- SAR - ANTI-TIPPING SYSTEM (LCD Display)

- Counter CAN Messages

- Work State

- SAR Exclusion Work State

- Calibration State

- LCD Display during Calibration of the Anti-tipping System

- Calibration sequence

- Errors State

- List of Errors Generated by Panel

- Anti-tipping System Test

- Safety functions of SRP/CS

- Features of each safety function

- Exact places where the parts relating to safety start and end

- Environmental conditions

- PL level of performance

- Parameters relating to reliability (MTTFd, DC, CCF and service time)

- Used technologies

- Logic foundations for designing (for example considered failures, excluded failures)

- Measures against reasonably predictable incorrect use

- Buzzer

- Buttons

- Changing display visualisation

- Clock setup

- Initial check

- Night--time lighting

- Line end calibration

- Connector

- Technical features

- Power supply

- Replacement of electrical cable

- Remove

- Installation

- 8. Electrical Circuits

Screenshots for New Holland Telehandler LM5030 PDF Set of Manuals:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for New Holland Telehandler LM5030 PDF Set of Manuals:

eTimGo AGCE for CNH EST 2025 all brands OFFLINE

eTimGo AGCE for CNH EST 05/2025 all brands OFFLINE. Manuals, electrical bulletin diagrams, and diagnostic procedures are provided, including some spare parts catalogs.

1200$

[05/2025]

|

New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software![Diagnostic Software New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software](https://www.epcatalogs.com/file/base/7wA2eiQzaw96Mud+nQLe62FMZmZxTTk819fwjKwFzn9gZlueS7pErMi5cA5I4B9rnJjvyM2KHVeYq8dAqLFqg6eVylUigwGA14M6GWQO8C:2FaqSq5rLX38HGZjM8wALuylflj8yTHY6HQGzotXlCesqQ=/case-new-holland-electronic-service-tools-cnh-est-software-download.png)

The dealer software Electronic Service Tools CNH EST 9.13 update 3 (ex v9.3, v9.4, v9.5, 9.6, 9.7) with the highest engineering access Level available for download or shipping worldwide with online support!

250$

[01/2026]

|

Original CNH DPA5 Diagnostic Service Tool Adapter Cable Kit + CNH EST 9.12

The Case, New Holland (CNH) DPA5 adapter kit includes all the cables. This is a genuine CNH DPA5 kit. Include CNH 9.12 Engineering Software 2025

1699$

[2025]

|

CNH Display Codes for the Paid Features 2023 v1.1

The app generates codes for CNH displays to unlock paid features. Codes are entered through the display

3999$

[2024]

|