![spare parts catalog CLAAS Parts Doc Offline Update v919 [02.2026]](/imgs/type_zapch.gif)

New Holland HW305, HW305S, HW325 Repair Manual PDF

[2006]This Repair Manual in PDF format has been developed and collected by specialists in order to maintain the work of New Holland HW305, HW305S, HW325 models for many years and to ensure safe and high-quality work.

It covers:

SECTION 00 - GENERAL INFORMATION

Description Page

00 000 Precautionary Statements

Safety

General Safety Information

Protecting the Electronic/Electrical Systems During Charging or Welding

Introduction

About Improvements

Product Identification Numbers (PIN)

Engine PIN Number

Company Policy

Parts and Accessories

Lubrication

Recommended Lubricants and Coolants

Sealants

Minimum Hardware Tightening Torques

Installation of Adjustable Fittings in Straight Thread O ring Bosses

Standard Torque Data for Hydraulic Tubes and Fittings

Pipe Thread Fitting Torque

Installation of ORFS (O ring Flat Faced) Fittings

Specifications

SECTION 10 - ENGINE

Description Page

Engine Overhaul Introduction

Description of Operation

Specifications

Special Tools

Torques

Overhaul

Engine

Removal

Turbocharger

Fuel System

Thermostat

Oil Cooler

Water Pump

Cylinder Head

Front Housing

Oil Pump

Rear Housing

Oil Pan

Timing Gears

Pistons

Main Bearings

Crankshaft

Oil Nozzles

Camshaft

Tappets

Block

Inspection

Crankshaft

Oil Pump Gear

Inspection, Removal, and Installation

Crankshaft

Installation for Inspection

Camshaft

Camshaft Bushings

Inspection and Installation

Tappets

Piston

Disassembly

Assembly

Connecting Rod

Bushings

Rod Markings

Connecting Rods

Piston and Connecting Rod

Assembly

Piston Rings

Piston and Rod Assembly

Installation for Clearance

Rod Bearing

Clearance

Piston

Height Measurement

Cylinder Head

Valve

Valve Seals

Removal

Inspection/Installation

Cylinder Head

Valves

Specifications

Valve Stem Play

Valve Guides

Valve Seats

Valve Springs

Inspection of the Intake and Exhaust Valve Springs

Cylinder Head

Installation

Push Rods

Rocker Arm Group

Installation

Block Assembly

Tappets

Camshaft

Oil Nozzles

Crankshaft

Piston and Connecting Rod

Timing Gearbox

Camshaft

Timing

Fuel Pump

Flywheel Housing

Oil Pump

Water Pump

Front Cover

Crankshaft Pulley

Oil Pan

Oil Cooling System

Injector Assembly

Valve Covers

Exhaust Manifold

Turbocharger

Engine

Troubleshooting

SECTION 25 - FRONT MECHANICAL DRIVE

Description Page

Description of Operation

Special Tools

Overhaul

Front Mechanical Drive

Removal

Installation

Planetary Gearbox Drive

Disassembly

Assembly

Labor Guide

SECTION 29 - HYDROSTATIC TRANSMISSION

Description Page

Specifications

Hydrostatic Transmission Identification

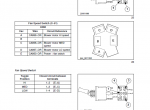

Torque Specifications

Torque Chart

Motor Area

Description of Operation

Pumps

High Pressure Relief Valves

Check Valves

Charge Pump

Charge Relief Valve (Pump)

Header Lift Pump

Motors

Fixed Displacement Motor

Variable Displacement Motor

Reservoir

Oil Flow

Neutral

Forward/Reverse

HW305/305S Hydraulic System Diagram

HW325 Hydraulic System Diagram

Solenoid Valve (2-Speed Drive Motor Only)

Low-Range Operation

High-Range Operation

Cooling Circuit

Relief Valve

Operation

Linkage

Operation

Sauer-Danfoss Authorized Service Centers -- North America

Troubleshooting

Excessive Noise

Overheating Transmissions

Loss of Propulsion

Control Linkage Inspection

High-Pressure Relief Valve Check

Charge Pump Relief Valve

Check Valve

Pressure Testing

Port Locations

Charge Pressure (HW305/305S)

Charge Pressure (HW325)

Charge Pressure System Test

Tandem Pump Charge Pressure Test

Complete Charge System Test (HW325 Only)

High Pressure Relief Valve Test

Gage Port and Relief Valve Locations

Pressure Port Locations

Case Pressure Test (Pump)

Case Pressure Test (Motor, HW325 only)

Suction Test

Case Flow Test (HW325 Only)

Ground Speed Circuit (HW305/305S)

Operation

Troubleshooting

Ground Speed Display Does Not Function (HW305/305S)

Ground Speed Circuit (HW325)

Operation

Troubleshooting

Ground Speed Display Does Not Function (HW325)

Troubleshooting Charts

Windrower Will Not Shift into High Range

Windrower Will Not Shift into Low Range

Charge Pump

Hydrostatic System

Explanation of Terms Used in Failure Analysis

Lack of Lubrication

Operating at Excessive Temperature Levels

Cavitation

Overspeeding of the Unit

Parts Worn or Scored From Contamination

Abrasive Contaminants

Plates Scored from Water in Oil (Non-Particle Contaminants)

Minor Repairs

Tandem Pump

Port Locations

Rear Half Port Breakdown

Front Half Port Breakdown

Shaft Seal Replacement

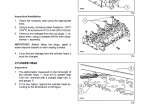

Charge Pump Removal

Charge Pump Inspection

Charge Pump Assembly

O Ring Seals

Trunnion Seal (Control Shaft Side)

Trunnion Cover (Plain)

Tandem Pump Removal

Tandem Pump Installation

Ground Drive Motor

Removal

Inspection/Parts Breakdown

Installation

Start-Up

Maintenance

Worm Shaft

Removal

Installation

SECTION 33 - BRAKES AND CONTROLS

Description Page

Description of Operation

Special Tools

Overhaul

Brake Assembly

Removal

Installation

Disassembly

Rotating, Stationary, and Primary Disc Assembly

Installation

Brake Bleeding Procedure

Labor Guide

SECTION 35 - HYDRAULIC SYSTEMS

SECTION 44 - REAR AXLE

Description Page

Introduction

Overview

Specifications

Special Tools

Description of Operation

Extensions and Axle Tube

Adjustments

Wheel Width

Channel Widths (Spindle to Spindle)

Axle Extension Position

Overhaul

Wheel, Axle Shaft and Hub

Removal

Inspection

Installation

Axle Support Fork

Removal

Inspection

Installation

Rear Axle Extension

Removal

Inspection

Installation

Axle Tube and Center Pivot Pin

Removal

Inspection

Installation

Labor Guide

SECTION 50 - CLIMATE CONTROL

SECTION 55 - ELECTRICAL SYSTEMS

SECTION 58 - HEADER ATTACHMENTS

Description Page

Overview

HW305 and HW305S Draper Floatation

Operation

Overhaul

Cut Height Cylinders

Removal

Inspection

Installation

Cartridge Valves

Removal

Installation

Hose Routing -- Cut Height Cylinders

Hose Routing

Removal

Installation

Hoses -- Valve to Valve

Removal

Installation

Without Deck Shift

With Deck Shift

Hydraulic System Check with Header Installed

Electrical System -- Fuse and Relay

Removal

Switches

Removal

Solenoid Connectors

Inspection

Troubleshooting -- Wire Harnesses

Harness Connectors and Wires

CN-C Wire Harness (Common Draper/Merger, Cab)

DR-C Wire Harness (Draper, Cab)

DR-FS4 Wire Harness, Flow Divider

DV-CS4 Wire Harness

DR-F Wire Harness (Draper, Main Frame)

LT-C Wire harness (Elec Counter Weight L Header Trim, Cab) Deck Shift Only

LT-F Wire harness (Elec Counter Weight L Header Trim, Main Frame) Deck Shift Only

Troubleshooting -- Draper System

Diagnostic Charts

Preliminary Diagnostic Chart

Accessing Diagnostic Mode

Energized Components

Header to Machine Connector

Theory of Operation -- Flow Divider

4 Cylinder Flow Divider Logic

Wire Identification

Fuse F-41 Power Chart

Fuse F-42 Power Chart

Schematics

SECTION 88 - OPTIONAL EQUIPMENT

Description Page

Optional Kits

Instructor Seat

Radio (A-17)

Installation

Wiper

Cab Heater

Adjustable Windrow Shield

Removal

Installation

Cold Start Kit

Removal and Replacement

Auxiliary Fuel Tank

Deluxe Lighting Kit

Service Flood Light

Replacing Power Outlets

Deluxe Header Tilt Indicator

Hydraulic Tilt Cylinder

Header Lift Arm Quick Latch Kit

Model HS Sickle Header Drive Adapter Kit

Removal

Disassembly

Shaft Removal

Assembly

Installation

Model 2300 Sickle Header Adapter Kit

Removal

Repair

Disassembly

Inspection

Assembly

Installation

Draper Header Drive Adapter Kit

Deck Shift Draper Header Adapter Kit

Header Power Reverser Kit

Hydraulic Reel Drive Kit

Engine Mounted Auxiliary Drive Pump

Auxiliary Hydraulic Filter

Swath Roller Hitch

Removal

Installation

Chaff Wiper Kit

Removal

Installation

SECTION 90 - PLATFORM, CAB AND DECALS

Description Page

Introduction

Overview

Overhaul

Air Ride Seat (HW305 and HW305S)

Removal

Disassembly

Inspection

Reassembly

Installation

Cab Door

Cab Door Handle

Disassembly

Cab Floor Mat

Console

Assembly

Steering Column

Wiper Motor

Remove and Replace

Stereo and Speaker System

Switches and Their Functions

Safety Decals

Repair Time Schedule

Failure to properly maintain equipment or to follow instructions contained in the tutorial could result in damage to the products, personal injury, property damage, or death. This comprehensive manual is suitable for professional technicians and novice mechanics alike.

Features of the Manual

Format: PDF

Language: English

Pages: 2030

Compatible with all versions of Windows, Mac, Linux, iPhone, iPad, and Android

The Electronic guide includes sections about special tools list, safety rules, technical data, operation, troubleshooting, engine instruction, maintenance procedures, many illustrations, different schemes, diagrams, etc.

FAQs

How do I download the manual?

After completing the purchase, you will receive a download link via email. Please check your spam/junk folder if you don't see it in your inbox.

Is the manual printable?

Yes, all pages are printable.

Still have questions?

Leave us a message and we will try to help.

Screenshots for New Holland HW305, HW305S, HW325 Repair Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for New Holland HW305, HW305S, HW325 Repair Manual PDF:

eTimGo AGCE for CNH EST 2025 all brands OFFLINE

eTimGo AGCE for CNH EST 05/2025 all brands OFFLINE. Manuals, electrical bulletin diagrams, and diagnostic procedures are provided, including some spare parts catalogs.

1200$

[05/2025]

|

New Holland Electronic Service Tool CNH EST 9.14 [2026] Engineering Diagnostic Software![Diagnostic Software New Holland Electronic Service Tool CNH EST 9.14 [2026] Engineering Diagnostic Software](https://www.epcatalogs.com/file/base/7wA2eiQzaw96Mud+nQLe62FMZmZxTTk819fwjKwFzn9gZlueS7pErMi5cA5I4B9rnJjvyM2KHVeYq8dAqLFqg6eVylUigwGA14M6GWQO8C:2FaqSq5rLX38HGZjM8wALuylflj8yTHY6HQGzotXlCesqQ=/case-new-holland-electronic-service-tools-cnh-est-software-download.png)

The dealer software Electronic Service Tools CNH EST 9.14 update 1 (ex v9.3, v9.4, v9.5, 9.6, 9.7) with the highest engineering access Level available for download or shipping worldwide with online support!

250$

[03/2026]

|

Original CNH DPA5 Diagnostic Service Tool Adapter Cable Kit + CNH EST 9.12

The Case, New Holland (CNH) DPA5 adapter kit includes all the cables. This is a genuine CNH DPA5 kit. Include CNH 9.12 Engineering Software 2025

1699$

[2025]

|

CNH Display Codes for the Paid Features 2023 v1.1

The app generates codes for CNH displays to unlock paid features. Codes are entered through the display

3999$

[2024]

|