![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

New Holland Crawler Dozer DC150.B (Tier 2) Workshop Manual PDF

[]The workshop manual designed for crawler dozer DC150.B New Holland. This manual is your assistant who's will help to solve problems with crawler dozer New Holland. Service manual contains a repair and maintenance information, technical information, special instructions, electrical and hydraulic circuits that will help the client to remove all the existing fault and many other (see below detailed contents).

This is a factory data, the description of the operation and maintenance of this equipment and spare parts, troubleshooting information, assembly and disassembly, inspection and control, safety precautions, special instructions, technical specification.

Thanks to the PDF format, in which the manual is presented, it is possible to print the entire instruction or the individual diagrams and schemes. You can work with this manual after installing Adobe PDF Reader.

Contents:

- 0. GENERALITIES

- SAFETY RULES

- IDENTIFICATION DATA

- TABLE OF FLUID CAPACITIES

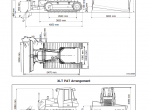

- TABLE OF CENTRE OF GRAVITY

- MAIN DIMENSIONS AND WEIGHTS

- TABLES OF TECHNICAL DATA

- CHECK DATA ON THE MACHINE

- EQUIPMENT MANOEUVRE TIMES

- LEAKAGES

- GENERAL INSTRUCTIONS

- DIAGNOSTIC CHECKS

- UNITS OF MEASURE

- TABLE OF TIGHTENING TORQUES

- 1. ENGINE

- GENERAL SPECIFICATIONS OF SERIES B ENGINE

- DESIGN FEATURES

- SERVICEABILITY

- SECURING THE ENGINE TO THE FRAME

- 2. TRANSMISSION

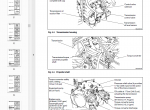

- GENERAL DESCRIPTION

- Transmission converter hydraulic diagram

- TROUBLESHOOTING

- TESTS

- Torque converter stall test

- Delivery pressure test procedure

- Transmission gear shifting electric control valve

- PROCEDURES FOR THE REPAIR OF THE TORQUE CONVERTER

- Removal

- Re-Installation

- Disassembly

- Reassembly

- PROCEDURES FOR THE REPAIR OF THE TRANSMISSION

- Removal

- Re-Installation

- Disassembly

- Overhaul of forwarding the speed clutch

- Overhaul of 3rd speed

- Overhaul of reverse speed clutch

- Modulating valves (Disassembly/Assembly)

- Pressure relief valve (Disassembly/Assembly)

- SPECIFICATIONS AND DATA

- General data

- Tightening Torques

- Tightening Torques

- Transmission Data

- 3. FINAL DRIVES

- GENERAL DESCRIPTION

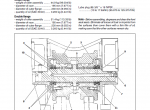

- Final drive (exploded view and sectional view)

- REPAIR PROCEDURES

- Final drive (removal/disassembly)

- Pulling the housing cover

- Driven gear (bearing removal)

- Driving gear shaft (bearing removal)

- Description of installation of front seals (long life)

- Final drive (assembly)

- SPECIFICATIONS AND DATA

- Final drive shaft and bearing fittings

- LIST OF OVERHAUL SPECIAL TOOLS

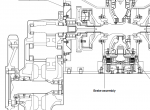

- 4. BRAKES AND STEERING DIFFERENTIAL

- GENERAL DESCRIPTION

- Brakes hydraulic diagram

- Main components of brakes circuit

- Steering hydraulic system diagram

- Main components of the steering circuit

- TROUBLESHOOTING

- Diagnosis on display

- TESTS

- Checking circuit pressures on diagnostics

- Adjusting the brake pedal

- Checks and setting on brake power valve block

- Calibration of steering levers

- REPAIR PROCEDURES

- Brake pedal valve (removal/disassembly)

- Brake power pump (removal/disassembly/re-assembly)

- Steering side group

- Bevel gear set (removal/disassembly of bevel pinion and crown gear)

- Brake group and pinion on the brake side

- Procedure and inspection for brake pack

- Installation of brake group

- Removal of brake pinion

- Disassembly of brake pinion

- Reassembly of brake pinion

- Installation of the crown gear

- Re-installation of pinion

- Procedure for the setting of the bevel pinion bearings pre-load

- (transmission side)

- Procedure for the setting of the bevel gear set

- Installation of the housing cover

- SPECIFICATIONS AND DATA

- Reduction bevel gear set

- The pinion on the brake side

- Brakes

- Brake pedal valve

- Rear transmission (transmission side section)

- 5. UNDERCARRIAGE

- GENERAL DESCRIPTION

- Generalities

- Main components

- TROUBLESHOOTING

- Slack track chain tension

- High track chain tension

- Insufficient tightening of the screws securing the shoes to the track chain

- Working on steep slopes

- INSPECTIONS

- Inspection and adjustment of track chains

- The setting of the track tensioner pressure relief valve

- REPAIR PROCEDURES

- Track chain (removal / installation)

- Replacing a damaged link and re-installation

- Idler (removal / installation / overhaul)

- Track chain support rollers (removal/installation/ overhaul)

- Track chain bottom rollers (removal / installation / overhaul)

- SPECIFICATIONS AND DATA

- Idler

- Sprockets

- Track chains

- Bottom rollers

- Support rollers

- Track tensioner device

- Front cross-member pivots

- Wear limits

- 6. DOZER EQUIPMENT

- GENERAL DESCRIPTION

- Operation of the hydraulic circuit

- Diagram of dozer equipment hydraulic system

- TESTS

- Use of flow-meter

- Delivery test in the single circuits

- REPAIR PROCEDURES

- Hydraulic oil tank (removal/installation)

- Equipment hydraulic pump

- Hydraulic control valve (removal/disassembly/overhaul)

- Installation of blade

- SPECIFICATIONS AND DATA

- Hydraulic control valve

- Power hydraulic valve

- Pilot valve power valve block

- Blade lifting cylinder joint

- Blade lifting control cylinder (Angledozer version)

- Blade lifting control cylinder (Bulldozer version)

- Blade tilt cylinder (PAT version)

- Blade tilt cylinder (Bulldozer version)

- Blade angle cylinder (version PAT for LT and XLT)

- Blade angle cylinder (PAT version for LGP)

- Ripper RP12F cylinder

- Ripper RP10F cylinder

- Push beams and blade rods

- C-frame and rods

- Ripper (Version LT, XLT)

- Ripper (Version LGP)

- 7. HYDRAULIC SYSTEM

- SAFETY RULES

- PROTECTION TREE ELECTRIC DIAGRAM

- Fuses

- Fuse links and cold starting fuse

- Main switch

- Engine starting switch

- Back-up alarm

- Starter motor

- ANGLE CONTROL

- INSTRUMENT PANEL/MONITOR

- Electric diagram of the monitor instrument panel

- MONITOR SENDERS

- DISPLAY

- Diagnosis on display

- BUZZER

- RELAY GROUP - DIODE BOXES - DIVERTER BOX

- 19 - 21 - 23 WAYS CONNECTORS

- 8. ELECTRICAL SYSTEM

- AIR CONDITIONING UNIT

- Operating instructions

- Technical data

- Cab climate conditioner and error codes

- Service precautions

- Tool connections

- Discharging

- Refrigerant charging

- Leak inspection

- Special tools

- Troubleshooting

Screenshots for New Holland Crawler Dozer DC150.B (Tier 2) Workshop Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for New Holland Crawler Dozer DC150.B (Tier 2) Workshop Manual PDF:

eTimGo AGCE for CNH EST 2025 all brands OFFLINE

eTimGo AGCE for CNH EST 05/2025 all brands OFFLINE. Manuals, electrical bulletin diagrams, and diagnostic procedures are provided, including some spare parts catalogs.

1200$

[05/2025]

|

New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software![Diagnostic Software New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software](https://www.epcatalogs.com/file/base/7wA2eiQzaw96Mud+nQLe62FMZmZxTTk819fwjKwFzn9gZlueS7pErMi5cA5I4B9rnJjvyM2KHVeYq8dAqLFqg6eVylUigwGA14M6GWQO8C:2FaqSq5rLX38HGZjM8wALuylflj8yTHY6HQGzotXlCesqQ=/case-new-holland-electronic-service-tools-cnh-est-software-download.png)

The dealer software Electronic Service Tools CNH EST 9.13 update 3 (ex v9.3, v9.4, v9.5, 9.6, 9.7) with the highest engineering access Level available for download or shipping worldwide with online support!

250$

[01/2026]

|

Original CNH DPA5 Diagnostic Service Tool Adapter Cable Kit + CNH EST 9.12

The Case, New Holland (CNH) DPA5 adapter kit includes all the cables. This is a genuine CNH DPA5 kit. Include CNH 9.12 Engineering Software 2025

1699$

[2025]

|

CNH Display Codes for the Paid Features 2023 v1.1

The app generates codes for CNH displays to unlock paid features. Codes are entered through the display

3999$

[2024]

|