![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Lombardini 15LD Series Engines for JCB Workshop Manual PDF

[11/2003]This workshop manual contains pertinent information regarding the repair of Lombardini water-cooled, indirect injection Diesel engines type 15LD225, 15LD315, 15LD350, 15LD400, 15LD440.

This manual contains repair tips, instructions for overhaul and proper operation, the descriptions of the device engines, many diagrams, and illustrations for Lombardini diesel engines.

This repair manual you can download in just a few seconds (Instant Download) will stay with you forever and will ensure you in any situation. Even an inexperienced user can use the Lombardini engine electronic service manual in PDF format.

This PDF manual will allow you to better master the skills of managing and operating Lombardini engines. Specialists in repair shops will also find a lot of useful service information in this manual, because even with significant repair experience, it is impossible to know everything, and specific repair information is required to perform complex procedures.

Publication No. 1-5302-467

Models covered:

15 LD 225,

15 LD 315,

15 LD 350,

15 LD 400,

15 LD 440.

CONTENTS:

- I TROUBLESHOOTING

- II SAFETY DECALS - SAFETY INSTRUCTIONS

- III MODEL NUMBER AND IDENTIFICATION

- IV TECHNICAL DATA

- V CHARACTERISTIC CURVES

- VI OVERALL DIMENSIONS

- VII MAINTENANCE- RECOMMENDED OIL TYPE - REFILLING

- VIII DISASSEMBLY / REASSEMBLY

- Automatic decompression

- Availability of bearings

- Cam height (mm)

- Camshaft

- Camshaft – Antireverse system

- Camshaft endplay

- Camshaft journals and bore

- Camshaft timing

- Clearance

- Connecting rod

- Connecting rod alignment

- Connecting rod, piston pin

- Crankshaft - journal diameter (mm)

- Crankshaft endplay

- Cylinder

- Cylinder head

- Cylinder roughness

- Dimensions and clearance between guides and valve stems (mm)

- Dimensions of camshaft journals and bore (mm)

- Dimensions of pistons and cylinders, Logo

- Dynamic balancer timing

- Driveshaft - Main bearing inside diameter, connecting rod big end, crankshaft bearing and timing control gear and balancer - Clearance and interference between the corresponding journals

- Driveshaft oil seals

- The driveshaft, connection radius

- The driveshaft, lubrication ducts, bore thread on flywheel side and p.t.o.

- The driveshaft, main journal/crankpin diameter, gear cover bearing inside diameter on the timing side

- Dry air cleaner for 15LD 225

- Dry air cleaner for 15LD 315 and 15 LD 350

- Dry air cleaner for 15LD 400-440

- Dynamic balancer (on request)

- Flywheel

- Fuel filter 15 LD 225-400-440 (version with internal filter)

- Fuel filter for 15 LD 225 - 315 - 350 - 400 - 440 (version with external filter)

- Hydraulic tappets 15 LD 400-440

- Injector projection

- Muffler

- Oil-bath air cleaner (optional)

- Piston

- Piston - Refitting

- Piston protrusion check

- Piston rings, assembly order

- Piston rings, distance between the tips (mm)

- Piston rings play between the slots (mm)

- Prefilter for dry air filter

- Re-coil starting

- Refitting gear cover on the timing side

- Rocker arm cover - Breather recirculation

- Rocker arm cover breather system

- Shroud

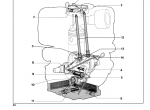

- Speed governor

- Speed governor removal

- Tank

- Timing angles for inspection (0.65-0.70 valve play).

- Timing angles for operation (0.15 valve play).

- Valve seat lapping

- Valve timing check

- Valve, springs

- Valve/rocker arm clearance ( 15 LD 225-315-350 )

- Valves - Disassembly

- Valves - Oil seal in the valve guide

- Valves seats and valve seat bores

- Valves, characteristics

- Valves, guide insertion

- Valves, guides, and housings

- IX LUBRICATION SYSTEM

- 15 LD 225 - 315 - 350 LUBRICATION SYSTEM

- 15 LD 400-440 LUBRICATION SYSTEM

- Calibrated

- Internal strainer

- Oil filter

- Oil pressure check

- Oil pressure curve at full speed

- Oil pressure curve at idle speed

- Oil pressure regulation valve

- Oil pump

- Oil pump - Clearance between rotors

- X FUEL SYSTEM

- Feed pump (optional)

- Fuel filter 15 LD 225-315-350-400-440

- Fuel filter 15LD 225 (version with the internal filter in the tank)

- Fuel pump, drive rod protrusion

- Fuelling/injection circuit for 15 LD 315-350-400-440

- Fuelling/injection circuit for 15LD 225

- Injection advance adjustment

- Injection pump

- Injection pump components and disassembly

- Injection pump delivery check on the test bench

- Injection pump fitting in the crankcase

- Injection pump non-return valve

- Injection pump refitting

- Injection pump, body, plunger, and delivery valve

- Injection pump, Rilsan tube refitting

- Injection pump, Rilsan tube removal

- Injector

- Injector calibration

- Nozzles

- References on the flywheel

- Static injection lead test on the flywheel

- Static injection timing

- XI ELECTRICAL SYSTEM

- 12V electric ignition layout with motor protection (optional)

- 12V electric starter diagram with the voltage regulator built into the ignition panel

- 12V, 12A electric ignition diagram

- 12V, 30A alternator battery recharging curve

- 24V, 9A alternator battery recharging curve

- Alternator

- Alternator battery charger graph (12V, 12A)

- Characteristic curves for starting motor type DW (L) 12V, 1.1 KW

- Characteristic curves of Bosch starter motor type DW (L) 12V, 0.9 kW

- Characteristic curves of Bosch starter motor type DW (L) 24V, 1.6 kW

- Diagram of electric starter motor protection with the sole self-winding starter - without battery - (optional)

- Ignition switch positions

- Starting motor

- Testing voltage regulator for proper operation

- Voltage regulator

- XII SETTINGS ADJUSTMENTS

- ADJUSTMENTS - 15 LD 315-350

- ADJUSTMENTS - 15 LD 225

- Full speed setting in no-load conditions (standard)

- Idle speed adjustment, for small car versions

- Idling speed setting in no-load conditions (standard)

- Injection pump delivery limiting and torque adapter (standard)

- Injection pump delivery setting

- Injection pump flow rate adjustment for 15LD 225-315-350

- No-load idling adjustment (standard)

- No-load top rate adjustment (standard)

- XIII STORAGE

- Temporary protection (1/6 months)

- Permanent protection (over 6 months)

- How to prepare the engine for operation

- XIV TORQUE SPECIFICATIONS

- Main torque specifications

- Use of sealant

- XV TORQUE SPECIFICATIONS

- Standard bolt torque specifications

Screenshots for Lombardini 15LD Series Engines for JCB Workshop Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Lombardini 15LD Series Engines for JCB Workshop Manual PDF:

Lombardini Gearbox for JCB Workshop Manual PDF

This PDF workshop manual contains the most important service information for the repair Lombardini GEARBOX (for JCB equipment).

49$

[03/2008]

|

Lombardini FOCS Series Engine for JCB Workshop Manual PDF

The PDF workshop manual gives the main instructions on how to repair Lombardini Diesel Engines LDW 502-602-903-1204-1204/T e LDW 702-1003-1404.

49$

[03/2008]

|

Lombardini CHD Series Engine for JCB Workshop Manual PDF

The PDF manual gives the main instructions on how to repair Lombardini diesel engines LDW 1503-1603-2004-2004/T-2204-2204/T, fluid cooling circuit.

49$

[12/2009]

|