![spare parts catalog CLAAS Parts Doc Offline Update v919 [02.2026]](/imgs/type_zapch.gif)

Komatsu Articulated Dump Truck HM300-5 Operation and Maintenance Manual PDF

[2014]This Operation and Maintenance Manual has been written in PDF format that is designed to meet the needs of technicians worldwide and to assist them in the efficient use, repair and maintenance of Komatsu Articulated Dump Truck HM300-5 models. Information is disclosed in more detail in all colorful illustrations, parts diagrams, wiring circuits, many tables, and different schemes.

Also, safety rules, specification instruction, operation information, system section, service recommendation, etc. Importantly for you, before any procedures with this Komatsu equipment, you should read all sections in this factory guide, especially the safety section to avoid injuries and technical failures.

This Komatsu information is prepared in PDF format and has 515 pages for reading. Immediately after purchase, you will receive this PDF file, sent by email to your email address, within several minutes after purchase. You can work with this factory guide information after installing Adobe PDF Reader.

TABLE OF CONTENTS:

FOREWORD

BEFORE READING THIS MANUAL

SAFETY INFORMATION

INTRODUCTION

MAIN USE OF MACHINE

DIRECTIONS OF MACHINE

VISIBILITY FROM OPERATOR'S SEAT

ACTIONS TAKEN TO MEET EXHAUST GAS REGULATIONS INFORMATION

LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

LOCATION OF EPA REGULATIONS, ENGINE NUMBER PLATE

SERVICE METER LOCATION

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

SAFETY

SAFETY

SAFETY LABELS

LOCATION OF SAFETY LABELS

CONTENTS OF SAFETY LABELS

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

PRECAUTIONS BEFORE STARTING OPERATION

PREPARATIONS FOR SAFE OPERATION

PRECAUTIONS TO PREVENT FIRE

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

DO NOT GET CAUGHT IN WORK EQUIPMENT

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES

UNAUTHORIZED MODIFICATION

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

PRECAUTIONS FOR OPERATION

PRECAUTIONS FOR JOBSITE

START ENGINE

PRECAUTIONS FOR OPERATION

TRANSPORTATION

TOWING AND BEING TOWED

PRECAUTIONS FOR MAINTENANCE

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

PRECAUTIONS FOR INSPECTION AND MAINTENANCE

TIRES

PRECAUTIONS FOR AdBlue/DEF

GENERAL CHARACTER AND PRECAUTIONS FOR HANDLING

PRECAUTIONS FOR ADDING

PRECAUTIONS FOR STORING

PRECAUTIONS FOR FIRE HAZARD AND LEAKAGE

OTHER PRECAUTIONS

OPERATION

GENERAL VIEW

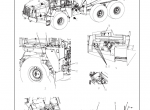

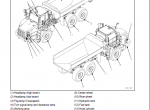

MACHINE EQUIPMENT NAME

CONTROLS AND GAUGES NAMES

OTHER EQUIPMENT NAME

EXPLANATION OF COMPONENTS

EXPLANATION OF MACHINE MONITOR EQUIPMENT

SWITCHES

CONTROL LEVERS AND PEDALS

OTHER EQUIPMENT

MACHINE OPERATIONS AND CONTROLS

CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

METHOD FOR STARTING ENGINE

METHOD FOR OPERATIONS AND CHECKS AFTER STARTING ENGINE

METHOD FOR STOPPING ENGINE

METHOD FOR CHECKING AFTER STOPPING ENGINE

START MACHINE (TRAVEL FORWARD AND REVERSE) AND STOP MACHINE

METHOD FOR SHIFTING GEARS

METHOD FOR TRAVELING DOWNHILL

METHOD FOR TURNING MACHINE

OPERATE WITH INTER-AXLE DIFFERENTIAL LOCK

HANDLE AUTOMATIC RETARDER, ACCELERATOR CONTROL (ARAC)

OPERATION OF ARAC SYSTEM

HANDLE KOMATSU TRACTION CONTROL SYSTEM (KTCS)

OPERATION OF KTCS SYSTEM

OPERATION IF TROUBLES ON SYSTEM OCCUR

OPERATION IF TIRES ARE STUCK IN GROUND

METHOD FOR LOADING

METHOD FOR DUMPING

METHOD FOR OPERATING CAB TILT

PRECAUTIONS FOR OPERATION

METHOD FOR PARKING MACHINE

METHOD FOR CHECKING AFTER FINISHING WORK

LOCK

HANDLE TIRE

HANDLE AIR CONDITIONER.

EXPLANATION OF AIR CONDITIONER EQUIPMENT

METHOD FOR OPERATING AIR CONDITIONER

HANDLE RADIO

EXPLANATION OF RADIO EQUIPMENT

METHOD FOR CONTROLLING RADIO

DUMP BODY HEATING SPECIFICATIONS

DETERMINE AND MAINTAIN TRAVEL ROAD

TRANSPORTATION

PRECAUTIONS FOR TRANSPORTATION

PRECAUTIONS FOR TRANSPORTING MACHINE

SELECT TRANSPORTATION METHOD

METHOD FOR SECURING MACHINE

PRECAUTIONS FOR LIFTING MACHINE

COLD WEATHER OPERATION

COLD WEATHER OPERATION INFORMATION

PRECAUTIONS AFTER DAILY WORK COMPLETION

AFTER COLD WEATHER SEASON

PRECAUTIONS FOR LONG-TERM STORAGE

PREPARATION FOR LONG-TERM STORAGE

MAINTENANCE DURING LONG-TERM STORAGE

STARTING MACHINE AFTER LONG-TERM STORAGE

PREPARATION BEFORE TRAVELING AFTER LONG-TERM STORAGE

TROUBLES AND ACTIONS

ACTIONS WHEN RUNNING OUT OF FUEL

ACTIONS IF TRANSMISSION HAS TROUBLE

METHOD FOR LOWERING DUMP BODY IN EMERGENCY

PRECAUTIONS FOR TOWING MACHINE

PRECAUTIONS FOR DISCHARGED BATTERY

ACTIONS IF DUMP BODY HEATING EXHAUST PIPING IS BROKEN TROUBLE

MAINTENANCE

PRECAUTIONS FOR MAINTENANCE

CHECK SERVICE METER READING

ALWAYS USE CLEAN WASHER FLUID

FRESH AND CLEAN LUBRICANTS

CHECK DRAINED OIL AND USED FILTER

PRECAUTIONS FOR REFILLING OIL OR FUEL

PRECAUTIONS FOR ADDING AdBlue/DEF

PRECAUTIONS FOR WELDING

DO NOT DROP THINGS INSIDE MACHINE

PRECAUTIONS FOR KDPF

PRECAUTIONS FOR SCR ASSEMBLY

DUSTY JOB SITES

AVOID MIXING OIL

LOCK INSPECTION COVERS

BLEED AIR FROM HYDRAULIC CIRCUIT

PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES

CHECKS AFTER INSPECTION AND MAINTENANCE

FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE

OUTLINE OF MAINTENANCE

HANDLE OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

HANDLE ELECTRICAL COMPONENTS

STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE TABLE

MAINTENANCE PROCEDURE

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS) REQUIRED

CHECKS BEFORE STARTING

EVERY 50 HOURS MAINTENANCE

EVERY 250 HOURS MAINTENANCE

EVERY 500 HOURS MAINTENANCE

EVERY 1000 HOURS MAINTENANCE

EVERY 2000 HOURS MAINTENANCE

EVERY 4000 HOURS MAINTENANCE

EVERY 4500 HOURS MAINTENANCE

EVERY 6000 HOURS MAINTENANCE

EVERY 8000 HOURS MAINTENANCE

EVERY 9000 HOURS MAINTENANCE

SPECIFICATIONS

SPECIFICATIONS

ATTACHMENTS AND OPTIONS

HANDLE CAB POWER TILT

HANDLING PAYLOAD METER

OUTLINE OF SYSTEM

NORMAL OPERATION DISPLAY

EXTERNAL DISPLAY LAMP

DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER

METHOD FOR DOWNLOADING DATA FROM CONNECTOR FOR DOWNLOAD

DISPLAY TOTAL PAYLOAD AND NUMBER OF CYCLES

DISPLAY FUEL CONSUMPTION RECORD

SETTING MACHINE ID AND OPEN ID

METHOD FOR PERFORMING CALIBRATION

REPLACEMENT PARTS

PERIODIC REPLACEMENT OF DEFINED LIFE PARTS

DEFINED LIFE PARTS LIST

CONSUMABLE PARTS

CONSUMABLE PARTS LIST

RECOMMENDED FUEL, COOLANT, AND LUBRICANT

LUBRICATION CHART

KOMATSU GENUINE REPLACEMENT PARTS

METHOD FOR USING FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

RECOMMENDED BRANDS AND QUALITIES OTHER THAN KOMATSU GENUINE OILS

INDEX

Screenshots for Komatsu Articulated Dump Truck HM300-5 Operation and Maintenance Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Komatsu Articulated Dump Truck HM300-5 Operation and Maintenance Manual PDF:

Komatsu Japan ALL Parts Catalog 2022

Parts catalog is an electronic database that includes a detailed parts list and accessories information for Komatsu equipment, intended for the Japanese market.

150$

[03/2022]

|

Komatsu USA ALL (Construction, Mining, Forestry, Utility) Parts Catalog 2022

Parts catalog is intended for Komatsu Construction, Mining, Foresty, Utility Equipment for American market.

250$

[03/2022]

|

Komatsu Construction Europe Parts Catalog 2022

Parts catalog includes original spare parts and accessories information for Komatsu construction equipment.

200$

[03/2022]

|

Full Forklift Package 2022

This Pack contains Factory parts catalogs, repair/workshop manuals for Jungheinrich, Linde, STILL STEDS, Toyota, Caterpillar, Komatsu, Manitou, Crown.

799$

[2022]

|