![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Kohler Diesel KDI 1903TCR-2504TCR for JCB Workshop Manual PDF

[04/2013]This workshop manual contains the instructions needed to carry out proper use and maintenance of the Kohler engine. Therefore it must always be available, for future reference when required. The service information, description, and pictures in this manual reflect the state of the art at the time of the marketing of the engine.

Form No. ED0053029590

Models covered:

1903TCR-2504TCR

Contents:

- 1. General Information

- 1.1 Manufacturer and engine identification

- 1.2 Nameplate for EPA regulations

- 2. Technical Information

- 2.1 Engine specifications

- 2.2 Engine dimensions

- 2.3 Performance diagrams

- 2.4 Oil

- 2.5 Fuel

- 2.6 Coolant

- 2.7 Battery features

- 2.8 Periodic maintenance

- 2.9 Fuel system

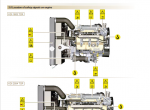

- 2.10 Lubrication circuit

- 2.11 Cooling circuit

- 2.12 Intake and exhaust circuit

- 2.13 Electric system

- 2.14 Sensors and switches

- 2.15 Electrical components

- 2.16 Timing system and tappets

- 2.17 Configurations with balancer shafts (optional)

- 2.18 Components handling

- 2.19 Turbocharger

- 3. Safety Information

- 3.1 Before start-up

- 3.2 Safety precautions

- 3.3 General remarks

- 3.4 Safety signal description

- 3.5 Information and safety signals

- 3.6 Safety and environmental impact

- 3.7 Safety signals

- 4. Storage Information

- 4.1 Product preservation

- 4.2 Engine storage (up to 6 months)

- 4.3 Engine storage (over 6 months)

- 4.4 Engine starting after storage

- 5. Liquid Drainage Information

- 5.1 Coolant

- 5.2 Engine oil

- 6. Information For Replacing The Functional Units

- 6.1 Electronic injector replacement

- 6.2 High-pressure pump replacement

- 6.3 Unit EGR cooler replacement

- 6.4 EGR valve replacement

- 6.5 Water pump replacement

- 6.6 Phonic wheel replacement

- 6.7 Oil pump replacement

- 6.8 Oil pressure valve replacement

- 6.9 Oil vapor separator replacement

- 6.10 Oil cooler unit and filter replacement

- 6.11 Fuel filter replacement

- 7. Disassembly Information

- 7.1 Recommendations for disassembly

- 7.2 Exhaust fumes recycle circuit disassembly (EGR)

- 7.3 Electric components disassembly

- 7.4 Turbocharger disassembly

- 7.5 Exhaust manifold disassembly

- 7.6 Water recirculation components disassembly

- 7.7 Engine pulley and phonic wheel disassembly

- 7.8 Lubrication circuit disassembly

- 7.9 Intake manifold disassembly

- 7.10 Injection circuit disassembly

- 7.11 Timing system gear disassembly

- 7.12 Flange unit disassembly

- 7.13 Cylinder head unit disassembly

- 7.14 Oil sump unit disassembly

- 7.15 Engine block disassembly

- 8. Information About Overhauling and Tuning

- 8.1 Recommendations for overhauls and tuning

- 8.2 Crankcase

- 8.4 Tappets and tapper housing

- 8.5 Crankshaft

- 8.6 Connecting rod - piston assembly

- 8.7 Cylinder head

- 8.8 Oil pump check

- 9. Assembly Information

- 9.1 Information on engine configuration

- 9.2 Assembly recommendations

- 9.3 Engine block assembly

- 9.4 Oil sump unit assembly

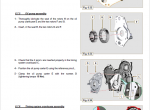

- 9.5 Flange unit assembly

- 9.6 Timing system gear assembly and high-pressure pump

- 9.7 Cylinder head unit assembly

- 9.8 Fuel system assembly

- 9.9 Intake manifold assembly

- 9.10 Exhaust manifold assembly

- 9.11 Assembly lubrication circuit

- 9.12 Engine pulley and phonic wheel assembly

- 9.13 Water circuit assembly

- 9.14 Turbo-compressor assembly

- 9.15 Electric component assembly

- 9.16 EGR circuit assembly

- 9.17 Summary table of tightening torques and the use of sealants

- 10. Fluids Supply Information

- 10.1 Engine oil

- 10.2 Coolant

- 11. Information About Optional Components

- 11.1 Oil dipstick in the cylinder head

- 11.2 Heater (replacement)

- 11.3 Poly-V alternator belt (replacement and adjustment)

- 11.4 Tightening pulley and alternator for Poly-V belt

- 11.5 Idler gear (for 3rd/4th PTO)

- 11.6 3rd PTO (replacement / installation)

- 11.7 4th PTO (replacement / installation)

- 11.8 Balancer shafts (replacement)

- 11.9 Air filter (cartridge replacement)

- 11.10 Remote oil filter (disassembly and assembly)

- 12. Information On Adjustments

- 12.1 Adjustment to "WASTE GATE" valve

- 13. Tools Information

- 13.1 Special tools

- 13.2 Commercial tools

- 14. Information About Failures

- 14.1 Possible causes and troubleshooting

- 15. Diagnostic Information

- 15.1 Diagnostic tool error list

- 15.2 Information on resources used in graphics software POLAR-XL

The workshop manual discusses the main malfunctions and in accordance with each case gives step-by-step instructions on how to fix the damage from the very beginning. This guide helps beginners and experienced professionals.

Features of the Manual

Format: PDF

Language: English

Pages: 204

Compatible with all versions of Windows, Mac, Linux, iPhone, iPad, and Android

The repair service manual is a rather narrowly specialized section of technical literature. This technical service manual presents detailed operating instructions, which are fully illustrated. Separately, the rules for maintenance of Kohler engines, taking into account the frequency of all preventive procedures. Carrying out the necessary inspections, checks, and adjustments, you can be calm for the excellent working condition of the equipment.

FAQs

How do I download the manual?

To purchase a catalog, click Buy Now. Fill out the proposed form and within a few minutes, a letter with all the recommendations and installation instructions will be sent to your e-mail.

Is the manual printable?

Yes, all pages are printable.

Still have questions?

If you have any questions or suggestions - write to us.

Screenshots for Kohler Diesel KDI 1903TCR-2504TCR for JCB Workshop Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Kohler Diesel KDI 1903TCR-2504TCR for JCB Workshop Manual PDF:

JCB ServiceMaster 4 2026 v25.12.0 Diagnostic Software

JCB ServiceMaster SM4 [12.2025] v25.12.0 is dealer-level (OEM) diagnostic software for agricultural and construction machinery and engines.

150$

[12/2025]

|

JCB PartsPlus+ Electronic Parts Catalog v2 (2.00.0004) 2017/01

OEM Electronic Parts Catalog for JCB - PartsPlus+ v2 (2.00.0004) 2017/01 is intended for searching parts of all JCB equipment. The JCB EPC application is available with the digital download and worldwide shipping.

200$

[01/2017]

|

JCB ServiceMaster Unlock Key generator (Normal, High Security, WinEEM4) v2.0

JCB ServiceMaster Security Unlock Key generator (Normal, High Security, WinEEM4) v2.0 Allows you to calculate response values for security unlock for all facilities in ServiceMaster 2 and 4 programs along with security parameters: reset EMS hours, change speed limit and many more.

300$

[2017]

|

JCB Wheel Loader 411HT, 413S, 417HT Service Manual PDF

PDF tutorial contains detailed information about the working device, technical information, safety, engine section, maintenance, and correct repair.

49$

[2016]

|