![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

JCB Side Engine Loadalls 540-140, 540-170, 535-125 Hi-Viz, 535-140 Hi-Viz Service Manual PDF

[]When a machine is correctly operated and properly maintained, it is a safe machine to work with. But when it is carelessly operated or poorly maintained it can become a danger to you (the operator) and others. That's why we recommend purchasing the PDF service manual.

This service manual covers detailed technical service information, routine maintenance instruction, description of current repair, lots of pictures and illustrations. This service repair manual is intended for JCB Side Engine Loadalls 540-140, 540-170, 535-125 Hi-Viz, 535-140 Hi-Viz.

In this manual and on the machine you will find warning messages. They tell you of potential hazards and how to avoid them.

To work with the service workshop manual, you need to use Adobe PDF Reader (or any other analog). This application will allow you to print out the manual in full or in part, or work with the manual on a computer/laptop.

We advise you to print the entire book, as the manual must always remain near the machine.

Publication No. 9813-1450-2

Models covered:

540-170,

540-140,

535-125 Hi Viz,

535-140 Hi Viz.

Note: this manual contains topics that relate to some or all JCB Loadall machines in the 5A group. There are several machine model codes in the family.

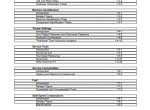

Contents:

- Section 1 - General Information

- Applications

- Use

- Machine Identification

- Torque Settings

- Service Tools

- Service Consumables

- Fuel

- Stall Speed Combinations

- Section 2 - Care and Safety

- Safety Notices

- General Procedures

- Section 3 - Routine Maintenance

- Related Topics

- Service Requirements

- Health and Safety

- Service Schedules

- Fluids, Lubricants and Capacities

- Prepare the Machine for Maintenance

- Cleaning the Machine

- Checking for Damage

- Greasing

- Access Panels

- Cab Heater and Air Conditioning

- Boom

- Brakes

- Electrical System

- Engine

- Fuel System

- Hydraulic System

- Transmission

- Tyres and Wheels

- Wheel Alignment

- Wear Pads

- Windscreen Washer

- Fire Extinguisher (if fitted)

- Section B - Body and Framework

- Applications

- Fork Carriage

- Cab Heating and Ventilation SYSTEM

- Cab Air Conditioning SYSTEM

- Longitudinal Load Moment SYSTEM (B-19-12)

- Longitudinal Load Moment SYSTEM (B-19-13)

- Fault Finding and Testing - LLMI

- Fault Finding and Testing - LLMC

- Cab

- Air Conditioning Condenser - Cooling Pack Mounted

- Air Conditioning Condenser - Cab Roof Mounted

- Cab HV and HVAC Unit

- Air Conditioning Binary Switch

- Heater Valve

- Fuel Tank

- Valve Block Covers

- Engine Cover

- Mudguards

- Chaff Guards

- Deckplate

- Boom

- Stabilisers

- Cab Side Cover

- Section C - Electrics

- Applications

- Fuses and Relays

- Schematics

- Electrical Harness SYSTEM

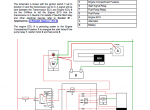

- Battery Charging SYSTEM

- Alternator (C-04-02)

- Battery

- Section E - Hydraulics

- Applications

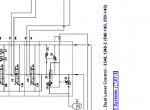

- Systems and Schematics

- Parallel Hydraulic SYSTEM (E-01-29)

- Parallel Servo Hydraulic SYSTEM (E-01-28)

- Parallel Circuit Operation (E-60-01)

- Parallel Servo Circuit Operation (E-60-10)

- Main Relief Valve (MRV)/Load Sense Relief Valve (LSRV) Operation

- Auxiliary Relief Valve (ARV) Operation

- Parallel Lift Operation (E-60-05)

- Hydraulic Interlock SYSTEM

- Boom Pressure Balance SYSTEM

- Universal Hydraulic Circuit Faults

- Parallel Circuit Faults

- Parallel Servo Circuit Faults

- Parallel SYSTEM Pressure Tests (E-61-05)

- Parallel Servo SYSTEM Pressure Tests (E-61-06)

- Pump Flow Tests - Gearpump (E-61-03)

- Parallel Control Valve - 6 Section

- Parallel Control Valve - 5 Section

- Parallel Control Valve - 2 Section

- Servo Control Valves

- Servo Solenoid Diverter Valve Block

- Stabiliser Isolation Valve

- Sway/Fan Changeover Valve

- Gearpump Operation

- Gearpump Removal and Replacement

- Hydraulic Cooling Fan Motor - Fixed Speed

- Variable Hydraulic Cooling Fan Control SYSTEM

- Hydraulic Operation and Schematics

- Hydraulic Cooling Fan Motor - Variable Speed

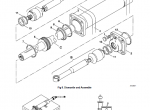

- Extension Ram

- Lift Rams

- Tilt Ram

- Displacement Ram

- Sway Ram

- Stabiliser Ram

- Ram Maintenance

- 3 Stage Boom - Extend Circuit - Bleed Procedure

- 4 Stage Boom - Extend Circuit - Bleed Procedure

- Tilt Circuit - Bleed Procedure

- Sway Circuit - Bleed Procedure

- Section F - Transmission

- Applications

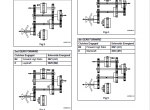

- CONFIGURATION

- Wheels and Tyres

- Front Axles

- Rear Axles

- PS750 Mk IV Gearbox SYSTEM

- PS764 Gearbox SYSTEM

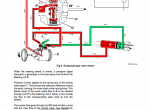

- PS750 Mk IV Hydraulic Operation

- PS760 Gearbox Hydraulic Operation

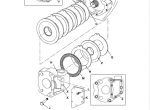

- Torque Converter Operation

- Gearbox Systems FAULT FINDING

- Flushing the Transmission Oil

- Torque Converter Stall Tests

- PS750 Mk IV Gearbox - Hydraulic Testing

- PS760 Gearbox - Hydraulic Testing

- Torque Converter

- PS750 Mk IV Gearbox

- PS760 Gearbox

- Bevel Gearbox

- Transmission Oil Cooler - Liquid to Liquid

- Transmission Oil Cooler - Air Blast

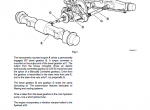

- Propshafts (F-10-06)

- Section G - Brakes

- Applications

- Twin Axle Service Brakes SYSTEM

- External Park Brake SYSTEM

- Internal Park Brake SYSTEM

- Park Brake Calliper

- Park Brake Disc

- Park Brake Switch

- Servo Exhauster Unit

- Servo Unit, Twin Axle Brakes

- Master Cylinder

- Fluid Reservoir

- Section H - Steering

- Applications

- Steering SYSTEM

- Manual Steer Mode SYSTEM

- Auto Steer Mode SYSTEM

- Hydraulic Steering Unit H-02-07

- Priority Valve

- Power Track Rod (H-07-06)

- Steer Rams

- Steering Column

- Manual Steer Mode Valve

- Auto Steer Mode Valve

- Steer Proximity Switches

- Section K - Engine

- Applications

- Engine Start/Stop SYSTEM

- Cold Start Heater SYSTEM

- Starter Motor (K-04-05)

- Cooling Pack (K-02-15)

- Coolant Expansion Tank (K-05-06)

- Throttle Position Sensor (TPS) (K-07-12)

- Air Cleaner Housing

- Exhaust Silencer (K-06-10)

- Fuel Cooler Matrix

- JCB EcoMax (SH, SL and DH)

- Section M - Electronic Data Systems

- Applications

- CANbus SYSTEM (M-01-07)

- Sub Section

- Fault Code SYSTEM

- Servicemaster SYSTEM

- Servicemaster Tool Set (M-04-08)

- Machine Diagnostic Tool User Guide (M-05-25)

- Cluster Set Up Tool User Guide (M-05-23)

- IFM Transmission Diagnostic Tool User Guide

- JCB EcoMax (SH,SL,DH) Engine Set Up Tool User Guide (M-05-21)

- JCB EcoMax (SH,SL,DH) Engine Diagnostics Tool User Guide (M-05-20)

- Boom Angle Sensor Calibration Tool - User Guide (M-05-14)

- Loadall Datalogger Tool - User Guide (M-05-12)

- Immobiliser Setup Tool (M-05-15)

- Immobiliser Diagnostics Tool (M-05-17)

- Pulse Width Modulation Theory

- Electronic Control Unit Theory

- Sub Section

- Devices

- Electronic Controllers

- Brake System Devices

- Cooling Fan Devices

- Engine and Fuel System Devices

- General Control Devices

- HVAC Devices

- Main Hydraulic Control Devices

- Boom/Chassis Sensor Devices

- Sub Section

- Stabiliser and Sway Devices

- Steer Mode Devices

- Transmission Devices

- Harness Interconnections

- Device Ground Points

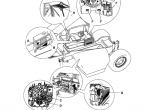

Screenshots for JCB Side Engine Loadalls 540-140, 540-170, 535-125 Hi-Viz, 535-140 Hi-Viz Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for JCB Side Engine Loadalls 540-140, 540-170, 535-125 Hi-Viz, 535-140 Hi-Viz Service Manual PDF:

JCB ServiceMaster 4 2026 v25.12.0 Diagnostic Software

JCB ServiceMaster SM4 [12.2025] v25.12.0 is dealer-level (OEM) diagnostic software for agricultural and construction machinery and engines.

150$

[12/2025]

|

JCB PartsPlus+ Electronic Parts Catalog v2 (2.00.0004) 2017/01

OEM Electronic Parts Catalog for JCB - PartsPlus+ v2 (2.00.0004) 2017/01 is intended for searching parts of all JCB equipment. The JCB EPC application is available with the digital download and worldwide shipping.

200$

[01/2017]

|

JCB ServiceMaster Unlock Key generator (Normal, High Security, WinEEM4) v2.0

JCB ServiceMaster Security Unlock Key generator (Normal, High Security, WinEEM4) v2.0 Allows you to calculate response values for security unlock for all facilities in ServiceMaster 2 and 4 programs along with security parameters: reset EMS hours, change speed limit and many more.

300$

[2017]

|

JCB Wheel Loader 411HT, 413S, 417HT Service Manual PDF

PDF tutorial contains detailed information about the working device, technical information, safety, engine section, maintenance, and correct repair.

49$

[2016]

|