![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

JCB Rear Engine Loadalls 526, 526S, 528-70, 528S Service Manual PDF

[]This manual explains how to properly operate and maintain the JCB Rear Engine Loadalls 526, 526S, 528-70, 528S. It contains instructions for safe use and preventative maintenance. All who are responsible for the work, maintenance and management should read and understand this manual. This is the only way to fully utilize all the capabilities of technology and ensure your safety.

The manual is compiled in sections, the first three are numbered and contain information as follows: General Information - includes torque settings and service tools; Care and Safety - includes warnings and cautions pertinent to aspects of workshop procedures etc; Maintenance - includes service schedules and recommended lubricants for all the machine.

The remaining sections are alphabetically coded and deal with Dismantling, Overhaul, etc. of specific components, for example, Attachments, Body, and Framework, etc.

This service repair manual is an electronic PDF book that works with any application that reads and supports PDF format. But we recommended using Adobe PDF Reader, that guarantee that all pages and pictures will open. For convenience, you can print some pages or the whole manual and use it as a handbook if necessary.

Publication No. 9803/3710-3

Models covered:

526 from SN 1182000,

526S from SN 1182000,

528-70 from SN 1182000,

528S from SN 1182000.

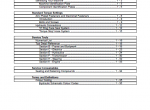

Contents:

- Section 1 - General Information

- Introduction

- Standard Torque Settings

- Service Tools

- Service Consumables

- Terms and Definitions

- Section 2 - Care and Safety

- Safety Notices

- Important Information

- Safety Checklist

- Safety Decals

- Section 3 - Routine Maintenance

- Health and Safety

- Service Schedules

- Fluids, Lubricants, and Capacities

- Cleaning the Machine

- Checking for Damage

- Seat Belt

- ROPS/FOPS Structure

- Boom Safety Strut

- Greasing

- Oiling

- Access Panels

- Brakes

- Electrical System

- Engine Air Filter

- Engine

- Fuel System

- Hydraulic System

- Transmission

- Tires and Wheels

- Axles

- Windscreen Washer

- Fire Extinguisher (if fitted)

- Section A - Attachments

- Service Procedures

- Section B - Body and Framework

- Technical Data

- Basic Operation

- Electrical Connections

- Fault Finding

- Service Procedures

- Air Conditioning (Option)

- Load Moment Indicator (LMI)

- Boom

- Cab

- Combined Fuel, Hydraulic Tank

- Engine Cover

- Section C - Electrics

- Technical Data

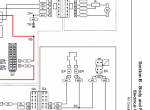

- Schematic Circuits

- Service Procedures

- Alternator

- Starter Motor

- Earth Points

- Harness Data

- Section E - Hydraulics

- Technical Data

- Basic Operation

- Schematic Circuits

- Circuit Descriptions

- Electrical Connections

- Fault Finding

- Service Procedures

- Main Pump

- Control Valve Block

- Servo Pilot Pressure Reducing Valve

- Solenoid Diverter Valve

- Hydraulic Rams

- Smooth Ride System (SRS)

- Section F - Transmission

- Technical Data

- Basic Operation

- Systems Description

- Electrical Connections

- Service Procedures

- Fault Finding

- Propshafts

- Removal and

- Front Axle SD70

- Rear Axle SD55

- Synchro Shuttle Gearbox

- Powershift Gearbox

- Torque Converter

- Oil Cooler

- Section G - Brakes

- Technical Data

- Basic Operation

- Fault Finding

- Service Procedures

- Master Cylinder

- Service Brakes

- Park Brake

- Section H - Steering

- Technical Data

- Basic System Operation

- Circuit Descriptions

- Electrical Connections

- Fault Finding

- Service Procedures

- Priority Valve

- Power Track Rod

- Steer Mode Valve (Option)

- Hydraulic Steer Unit

- Section K - Engine

- Technical Data

- Electrical Connections

- Cooling Pack

- Removal and Replacement

Screenshots for JCB Rear Engine Loadalls 526, 526S, 528-70, 528S Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for JCB Rear Engine Loadalls 526, 526S, 528-70, 528S Service Manual PDF:

JCB ServiceMaster 4 2026 v25.12.0 Diagnostic Software

JCB ServiceMaster SM4 [12.2025] v25.12.0 is dealer-level (OEM) diagnostic software for agricultural and construction machinery and engines.

150$

[12/2025]

|

JCB PartsPlus+ Electronic Parts Catalog v2 (2.00.0004) 2017/01

OEM Electronic Parts Catalog for JCB - PartsPlus+ v2 (2.00.0004) 2017/01 is intended for searching parts of all JCB equipment. The JCB EPC application is available with the digital download and worldwide shipping.

200$

[01/2017]

|

JCB ServiceMaster Unlock Key generator (Normal, High Security, WinEEM4) v2.0

JCB ServiceMaster Security Unlock Key generator (Normal, High Security, WinEEM4) v2.0 Allows you to calculate response values for security unlock for all facilities in ServiceMaster 2 and 4 programs along with security parameters: reset EMS hours, change speed limit and many more.

300$

[2017]

|

JCB Wheel Loader 411HT, 413S, 417HT Service Manual PDF

PDF tutorial contains detailed information about the working device, technical information, safety, engine section, maintenance, and correct repair.

49$

[2016]

|