![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

JCB Backhoe Loaders Service Manual PDF

[03/2015]This service manual includes maintenance and repair information of JCB Backhoe Loaders. This repair publication contains a separate section 'Operator's Manual'. It is intended to give you a good overview of the product and its safe operation. The workshop manual also contains maintenance and technical data.

This operator's manual provides service information for the following models in the JCB machine range:

Model From: To:

3CX T4F 02254521 02274521

4CX T4F 02254521 02274521

Service Manual Publication No. 9813/0250-07

Operator's Manual Publication No. 9831/0400 - ISSUE 2

Contents:

- Section 1 - General Information

- Introduction

- Safety

- Use

- Routine Maintenance

- General Procedures

- Service Consumables

- Torque Settings

- Stall Speed Combinations

- Service Tools

- Section 2 - Operator Manual

- Introduction

- About the Product

- Operation

- Attachments

- Preservation and Storage

- Maintenance

- Technical Data

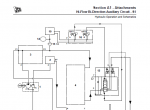

- Section A - Attachments

- Applications

- Hi-Flow Bi-Direction Auxiliary Circuit - S1

- Hi-Flow Bi-Direction Auxiliary Circuit - S2

- Hi-Flow Bi-Direction Auxiliary Circuit - S3

- Hi-Flow Bi-Direction Auxiliary Circuit - S4

- Hi-Flow Hammer Circuit - S1

- Hi-Flow Hammer Circuit - S2

- Hi-Flow Hammer Circuit - S3

- Hydraulic Tool Circuit (HTC) - S1

- Hydraulic Tool Circuit (HTC) - S2

- Hydraulic Tool Circuit (HTC) - S3

- Hydraulic Tool Circuit (HTC) - S4

- Excavator Hydraulic Quick hitch

- Automatic Excavator Quick hitch SYSTEM

- Hydraulic Thumb (Excavator)

- Section B - Body and Framework

- Applications

- Cab Air Conditioning SYSTEM

- Overload Warning SYSTEM

- Stabiliser Leg Alarm SYSTEM - S1

- Stabiliser Leg Alarm SYSTEM - S2

- Air Conditioning Condenser

- Cab HVAC Unit

- Binary Switch

- Air Conditioning Compressor

- Heater Valve

- Stabiliser Legs - Sideshift

- Stabiliser Legs - Centremount

- Boom

- Dipper

- Inner Dipper

- Kingpost

- Carriage

- Hydraclamps

- Power Sideshift - S1

- Power Sideshift - S2

- Hydraulic Tank - S1

- Hydraulic Tank - S2

- Fuel Tank - S1

- Fuel Tank - S2

- Engine Cover

- Front Grille Housing

- Engine Cover Support Frame - S1

- Engine Cover Support Frame - S2

- Front Bumper / Counterweight

- Chassis Panels - Side Rails

- Inner Dipper Wear Pads

- Cold Climate Heating SYSTEM

- Auto Boom Lock

- Routine Maintenance Procedures

- Section C - Electrics

- Applications

- Fuses and Relays

- Schematics

- Electrical Harness SYSTEM

- Alternator (C-04-01)

- Alternator (C-04-02)

- Battery

- Routine Maintenance Procedures

- Section E - Hydraulics

- Applications

- Systems and Schematics

- Manual Controls Hydraulic SYSTEM

- Manual Controls - Vari Hydraulic SYSTEM

- EasyControl Hydraulic SYSTEM

- EasyControl - Vari Hydraulic SYSTEM

- Advanced EasyControl Hydraulic SYSTEM

- Advanced EasyControl Plus Hydraulic SYSTEM

- Auto Smooth Ride SYSTEM (SRS)

- Ram Creep Tests

- Excavator Valve - Parallel Type - S1

- Excavator Valve - Closed Centre Type

- Loader Valve - Parallel Type

- Loader Valve - Closed Centre Type

- Pilot Pressure Supply Valve

- Pilot Changeover Valves

- Hydraclamp Valve

- Shovel Reset Valve

- HPCO Manifold

- Hose Burst Check Valves (HBCV) - S1

- Hose Burst Check Valves (HBCV) - S2

- Main Pump - Gear Type (P1/P2)

- Main Pump - Gear Type (Pump 3)

- Main Pump - Variflow Type

- Rams

- Excavator Control Levers

- Loader Control Levers

- Joystick Controllers

- Stabilisers Controller

- Auxiliary Foot Pedal Control

- Oil Cooler Matrix

- Routine Maintenance Procedures

- Section F - Transmission

- Applications

- Wheels and Tyres

- Front Axles

- Rear Axles

- SS700 Gearbox SYSTEM

- SS750 Gearbox SYSTEM

- PS764 Gearbox SYSTEM

- PS766 Gearbox SYSTEM

- Torque Converter Lock Up SYSTEM

- Gearbox Systems FAULT FINDING

- Torque Converter Stall Tests

- Flushing the Transmission Oil

- Shiftmaster ECU

- SS700 Gearbox

- SS750 Gearbox

- PS760 Gearbox

- Torque Converter

- Oil Cooler Matrix

- Propshafts

- Speed Sensors

- Gearbox Mountings

- Routine Maintenance Procedures

- Section G - Brakes

- Applications

- Service Brakes SYSTEM

- Internal Park Brake SYSTEM

- External Park Brake SYSTEM

- Brake Valve

- Combined Priority/Charge Valve - S1

- Combined Priority/Charge Valve - S2

- Park Brake Calliper

- Park Brake Disc

- Park Brake Switch

- Routine Maintenance Procedures

- Section H - Steering

- Applications

- Steering SYSTEM

- Hydraulic Steer Unit

- Priority Valve

- Power Track Rod

- Steering Column

- Auto Steer Mode Valve

- Steer Mode ECU

- Steer Mode Select Switch

- Section K - Engine

- Applications

- Start and Stop SYSTEM (Mechanical F.I. Engines)

- Inlet Manifold Heater SYSTEM

- Starter Motor

- Coolant Expansion Tank - S1

- Coolant Expansion Tank - S2

- Cooling Pack - S1

- Cooling Pack - S2

- Cooling Pack - S3

- Cooling Fan Viscous Coupling

- Fuel Cooler

- Throttle Cable

- JCB Dieselmax and Ecomax

- Air Filter Housing and Ducts

- Air Filter Vacuum Switch

- Silencer - Mechanical F.I. Engines

- Silencer - Electronic F.I. Engines

- Electronic F.I. Engine - Machine Devices

- SCR Systems

- Routine Maintenance Procedures

- Section M - Electronic Control Systems

- Applications

- CANbus SYSTEM

- RH Instrument Cluster - S1

- RH Instrument Cluster - S2

- Immobiliser Devices

- Automate Systems

- Fault Code SYSTEM

- Servicemaster SYSTEM

- Servicemaster Tools Set

- Shiftmaster 2.3 Diagnostics Tool

- Immobiliser Setup Tool (M-05-15)

- Immobiliser Diagnostics Tool (M-05-17)

- RH Instrument Cluster Setup Tool

- Pulse Width Modulation Theory

- Electronic Control Unit Theory

This comprehensive manual is suitable for professional technicians and novice mechanics alike.

Features of the Manual

Format: PDF

Language: English

Pages: 3619

Compatible with all versions of Windows, Mac, Linux, iPhone, iPad, and Android

This service guide contains procedures for routine maintenance tasks, technical service schedules, describes daily and weekly procedures, detailed original instructions, a variety of pictures and diagrams, and descriptions of the necessary tools.

FAQs

How do I download the manual?

To purchase these PDF guides, click the 'Buy Now' button. Fill out the proposed form, and within a few minutes, a letter with all the recommendations and installation instructions will be sent to your email. Please check your spam/junk folder if you don't see it in your inbox.

Is the manual printable?

This application helps you to copy, save, and print the needed repair and service information.

Still have questions?

If you have any questions or suggestions - write to us.

Screenshots for JCB Backhoe Loaders Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for JCB Backhoe Loaders Service Manual PDF:

JCB ServiceMaster 4 2026 v25.12.0 Diagnostic Software

JCB ServiceMaster SM4 [12.2025] v25.12.0 is dealer-level (OEM) diagnostic software for agricultural and construction machinery and engines.

150$

[12/2025]

|

JCB PartsPlus+ Electronic Parts Catalog v2 (2.00.0004) 2017/01

OEM Electronic Parts Catalog for JCB - PartsPlus+ v2 (2.00.0004) 2017/01 is intended for searching parts of all JCB equipment. The JCB EPC application is available with the digital download and worldwide shipping.

200$

[01/2017]

|

JCB ServiceMaster Unlock Key generator (Normal, High Security, WinEEM4) v2.0

JCB ServiceMaster Security Unlock Key generator (Normal, High Security, WinEEM4) v2.0 Allows you to calculate response values for security unlock for all facilities in ServiceMaster 2 and 4 programs along with security parameters: reset EMS hours, change speed limit and many more.

300$

[2017]

|

JCB Wheel Loader 411HT, 413S, 417HT Service Manual PDF

PDF tutorial contains detailed information about the working device, technical information, safety, engine section, maintenance, and correct repair.

49$

[2016]

|