![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Fiat Kobelco E200SR Evolution Crawler Excavator Workshop Manual PDF

[04/2003]This workshop manual is intended for serve and repair Fiat Kobelco Crawler Excavator E200SR Evolution.

Workshop manual contains the technical information necessary for

machine/engine service and repair, service equipment, information on maintenance standards, remove and install procedures, disassembly and assembly procedures.

This workshop manual is a file PDF, which contains 915 pages, any one of which we can be printed easily. We recommend using Adobe PDF Reader, to be sure all images/graphics will display correctly.

Workshop manual helps to identify existing and potential problems, to carry out maintenance and repair problem areas and troubleshooting.

INDEX:

- SPECIFICATIONS

- Section 1 - Outline

- 1. GENERAL PRECAUTIONS FOR MAKING REPAIRS

- 2. INTERNATIONAL UNIT CONVERSION SYSTEM

- Section 2 - Specification

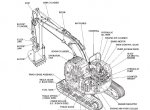

- 1. NAME OF COMPONENTS

- 2. GENERAL DIMENSION

- 3. WEIGHT OF COMPONENTS

- 4. TRANSPORTATION DIMENSION AND WEIGHT

- 5. SPECIFICATIONS AND PERFORMANCE

- 6. TYPE OF CRAWLER

- 7. TYPE OF BUCKET

- 8. COMBINATIONS OF ATTACHMENT

- 9. ENGINE SPECIFICATION

- Section 3 - Attachment dimension

- 1. BOOM

- 2. ARM

- 3. BUCKET

- MAINTENANCE

- Section 11 - Tools

- 1.TIGHTENING TORQUES FOR CAPSCREWS AND NUTS

- 2. SCREW SIZE

- 3. TIGHTENING TORQUES FOR NUTS AND SLEEVES

- 4. PLUG

- 5. SPECIAL SPANNER FOR TUBE

- 6. SPECIAL TOOLS

- 7. APPLICATION OF SCREW LOCKING COMPOUND AND SEALING COMPOUND

- 8. SUCTION STOPPER

- 9. COUNTERWEIGHT LIFTING JIG

- 10. UPPER FRAME LIFTING JIG

- 11. ENGINE MOUNTING PEDESTAL

- 12. TRACK SPRING SET JIG

- Section 12 - Standard maintenance time schedule

- 1. STANDARD MAINTENANCE TIME SCHEDULE FOR EXCAVATOR

- 2. STANDARD WORKING TIME TABLE FOR THE MAINTENANCE OF ENGINE

- Section 13 - Maintenance standard and test procedure

- 1. HOW TO USE THE MAINTENANCE STANDARD AND CAUTIONS TO BE EXERCISED

- 2. PERFORMANCE INSPECTION STANDARD TABLE

- 3. MEASUREMENT OF ENGINE SPEED

- 4. MEASUREMENT OF HYDRAULIC PRESSURE

- 5. MEASURING TRAVEL PERFORMANCES

- 6. MEASURING SWING PERFORMANCES

- 7. MEASURING ATTACHMENT OPERATING PERFORMANCES

- 8. MEASURING PERFORMANCES OF SWING BEARING

- 9. MECHATRO CONTROLLER “A” ADJUSTMENT

- SYSTEM

- Section 21 - Mechatro control system

- 1. SUMMARY OF MECHATRO CONTROL SYSTEM

- 2. MECHATRO CONTROLLER

- Section 22 - Hydraulic system

- 1. SUMMARY

- 2. HYDRAULIC CIRCUITS AND COMPONENT

- 3. OPERATION EXPLANATION OF HYDRAULIC CIRCUITS

- 4. PILOT PIPING

- 5. MAIN PIPING

- Section 23 - Electric system

- 1. ELECTRIC CIRCUIT DIAGRAM

- 2. ELECTRICAL EQUIPMENT LIST

- 3. HARNESS

- Section 24 - Components system

- I. HYDRAULIC COMPONENTS

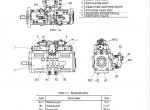

- 1. Hydraulic Pump_Regulator

- 2. Pilot Valve (ATT)

- 3. Pilot Valve (Travel)

- 4. Control Valve

- 5. Swing Motor Unit

- 6. Travel Motor

- 7. Swivel Joint

- 8. Hydraulic Cylinder

- II. ELECTRIC EQUIPMENT

- 1. List of Electric Equipments

- 2. Specification of Electric Equipments

- Section 25 - Air-conditioner system

- 1. CONSTRUCTION AND PIPING

- 2. CONSTRUCTION OF MAIN COMPONENTS

- 3. FUNCTION

- 4. DISASSEMBLY AND ASSEMBLY

- 5. CHARGING REFRIGERANT

- 6. ELECTRIC CIRCUIT

- 7. TROUBLESHOOTING

- DISASSEMBLING

- Section 31 - Disassembling and assembling

- 1. EXPLAINING CHAPTER OF WHOLE DISASSEMBLY & ASSEMBLY

- Section 32 - Attachment

- [Part I. Removing and Installing Assy]

- 1. ATTACHMENT ASSY AND NAME

- 2. BUCKET

- 3. ARM

- 4. BOOM

- [Part II. Disassembling and assembling equipment]

- 1. CYLINDER

- Section 33 - Upper structure

- [Part I. Removing and Installing Assy]

- 1. CAB

- 2. OPERATOR SEAT

- 3. BATTERY

- 4. GUARD

- 5. UNDERCOVER

- 6. FUEL TANK

- 7. HYDRAULIC TANK

- 8. HYDRAULIC PUMP

- 9. AIR CLEANER

- 10. MUFFLER

- 11. COUNTERWEIGHT

- 12. RADIATOR & OIL COOLER

- 13. ENGINE

- 14. INSTRUMENT PANEL

- 15. MULTI CONTROL VALVE (OPT)

- 16. CONTROL VALVE

- 17. PILOT VALVE (FOR ATT)

- 18. PILOT VALVE (FOR TRAVEL)

- 19. SWING MOTOR UNIT

- 20. SWIVEL JOINT

- 21. UPPER FRAME

- [Part II. Disassembling and assembling equipment]

- 1. PUMP

- 2. CONTROL VALVE

- 3. PILOT VALVE (FOR ATT)

- 4. PILOT VALVE (FOR TRAVEL)

- 5. SWING MOTOR UNIT

- 6. SWIVEL JOINT

- Section 34 - Travel system

- [Part I. Removing and Installing]

- 1. TRAVEL SYSTEM

- 2. CRAWLER

- 3.UPPER ROLLER

- 4. LOWER ROLLER (TRACK ROLLER)

- 5. FRONT IDLER

- 6. SPROCKET

- 7. TRAVEL REDUCTION UNIT

- 8. SWING BEARING

- [Part II. Disassembling and assembling equipment]

- 1. TRAVEL MOTOR

- TROUBLESHOOTING

- Section 41 - Troubleshooting (mechatro control)

- 1. OUTLINE

- 2. TABLE OF ACTUATOR FOR TROUBLESHOOTING

- 3. TROUBLESHOOTING OUTLINE

- 4. CHECKPOINT FOR MECHATRO SYSTEM

- Section 42 - Troubleshooting (Hydraulic)

- 1. TROUBLE DIAGNOSIS TABLE

- 2. TROUBLESHOOTING

- Section 43 - Troubleshooting (Electric)

- 1. TROUBLE DIAGNOSIS TABLE

- 2. SELF DIAGNOSIS TABLE

- 3. SERVICE DIAGNOSIS TABLE

- 4. TROUBLESHOOTING

- Section 44 - Troubleshooting (Engine)

- 1. TROUBLE DIAGNOSIS TABLE

- 2. TROUBLESHOOTING

- ENGINE

- Section 51 - Engine

- 1. GENERAL INFORMATION

- 2. MAINTENANCE

- 3. DISASSEMBLY

- 4. INSPECTION & REPAIR

- 5. REASSEMBLY

- 6. LUBRICATING SYSTEM

- 7. COOLING SYSTEM

- 8. FUEL SYSTEM

- 9. TURBOCHARGER

- 10. AIR COMPRESSOR

- 11. ENGINE ELECTRICALS

- 12. TROUBLESHOOTING

- 13. SPECIAL TOOL LIST

- 14. CONVERSION TABLE

- OPT

- Section 63 - Mounting the breaker and nibbler & breaker

- 1.LIST OF ADDITIONAL PARTS

- 2. SUMMARY

- 3. HYDRAULIC CIRCUIT DIAGRAM

- 4. ELECTRIC SYSTEM DIAGRAM FOR NIBBLER & BREAKER

- 5. MODIFICATION PROCEDURE FOR NIBBLER & BREAKER

- 6. MODIFICATION PROCEDURE FOR BREAKER

- 7. MODIFICATION PROCEDURE FOR ATTACHMENT

- 8. REMINDERS ON THE USE OF NIBBLER & BREAKER

- 9. PRECAUTIONS TO BE EXERCISED ON BREAKERS OF DIFFERENT MANUFACTURES

- 10. REFERENCE

Screenshots for Fiat Kobelco E200SR Evolution Crawler Excavator Workshop Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Fiat Kobelco E200SR Evolution Crawler Excavator Workshop Manual PDF:

Fiat Kobelco EX95W Compact Line Excavator Workshop Manual PDF

PDF workshop manual provides service information, adjustment and testing instructions, troubleshooting information for Fiat Kobelco Excavator EX95W.

50$

[07/2002]

|

Fiat Kobelco EX455 Tier2 Excavator Technical Manual PDF

PDF technical manual includes service and repair information, installation instructions, maintenance information for Fiat Kobelco excavators EX455 Tier2.

40$

[07/2002]

|

Fiat Kobelco T13, T14, T17 Telehandlers Service Manual PDF

PDF service guide includes repair instructions, technical service information, diagrams, specifications for Fiat Kobelco Telehandlers T13, T14, T17.

50$

[03/2004]

|

Fiat Kobelco SL65B Compact Loader With Accessories Workshop Manual PDF

To service Fiat Kobelco Compact Loader SL65B, you need to use this PDF workshop manual.

50$

[07/2002]

|