![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Features of the Manual

- Comprehensive Repair Information: Step-by-step procedures for repairing and servicing your equipment.

- Maintenance Schedules: Detailed plans for routine maintenance to extend equipment lifespan.

- Technical Specifications: In-depth technical data for all components.

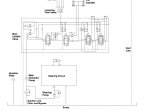

- Electrical Schematics: Detailed diagrams of electrical systems for troubleshooting.

- Fitting Instructions: Guidance on proper installation of parts and components.

- User-Friendly Search Function: Quickly locate the information you need using Acrobat's search feature.

Designed with the user in mind, this manual helps you perform repairs accurately and safely, minimizing downtime and ensuring optimal performance.

Manual Contents

- Truck Models Covered by This Manual

- Arrangement and Use of This Manual

- Foreword

- Contents

- Group SA - Safe Maintenance

- Safety

- Lifting, Jacking, and Blocking

- Group PS - Periodic Service

- Maintenance Schedules

- Planned Maintenance

- The PM Inspection Form

- Group 12 - Battery

- Battery Handling

- Battery Tests

- Group 13 - Electrical Switches

- Foot and Hand Brake Switches

- Lift and Tilt Pump Switches

- Forward and Reverse Switches

- Group 16 - Electrical Motors

- General Information

- Drive Motor

- Hydraulic Pump Motor

- Steering Pump Motor

- Group 17 - Electrical Schematics

- Wiring Schematics and Diagrams

- Group 19 - Electrical Controls

- Control Panel

- EW200LX Troubleshooting

- Recommended Tests, Equipment, and Procedures

- Periodic Electrical Checks

- Battery Tests

- EV100 LXT Control Panel

- Status Codes

- Group 20 - Drive Axle

- Specifications and Description

- Troubleshooting

- Removal and Installation

- Overhaul Practices

- Axle Ends Overhaul

- Differential Adaptor Overhaul

- Differential Overhaul

- Group 22 - Wheels and Tires

- Specifications and Description

- Cushion Wheels and Tires

- Group 23 - Brake System

- Specifications and Descriptions

- Service Brake Troubleshooting

- Pedal and Linkage Adjustments

- Brake System Bleeding

- Master Cylinder Service

- Service Brake Overhaul

- Park Brake Service

- Group 25 - Steering Column and Gear

- Specifications and Description

- Troubleshooting

- Column Removal and Installation

- Relief Pressure Check and Adjustment

- Gear Overhaul

- Group 26 - Steering Axle

- Specifications and Description

- Wheel Bearing Maintenance and Adjustment

- Axle Removal and Installation

- Axle Overhaul

- Cylinder Removal and Installation

- Cylinder Overhaul

- Pump Removal and Installation

- Pump Overhaul

- Group 29 - Hydraulic Sump, Filters, and Pump

- Specifications and Description

- Pump Troubleshooting

- Filters and Fluid Maintenance

- Pump Removal and Installation

- Pump Overhaul

- Group 30 - Hydraulic Control Valves

- General Description

- Valve Removal and Installation

- Valve Disassembly, Inspection, and Assembly

- Group 32 - Tilt Cylinders

- Specifications and Description

- Checks and Adjustments

- Removal and Installation

- Overhaul

- Group 34 - Uprights

- Specifications and Descriptions

- Troubleshooting

- Inspection

- Roller Clearance Checks and Shim Adjustments

- Chain Inspection, Adjustment, and Installation

- Fork and Carriage Removal and Installation

- Group 38 - Counterweight and Chassis

- Specifications and Description

- Counterweight Removal and Installation

- Overhead Guard Removal and Installation

- Floor Plate and Seat Deck Removal and Installation

- Operator’s Seat Removal and Installation

- Group 40 - Specifications

- Nameplate and Decals

- General Specifications

- Hydraulic Fitting Tightening Procedure

Digital PDF Format

The manual is provided in a convenient PDF format that is compatible with both Windows and Mac operating systems and mobile OS like Android and iOS. Key features include:

- Language: English

- User-Friendly Interface: Easy navigation with a searchable text function using Acrobat Reader.

- Printable Pages: Print individual sections or the entire manual as needed.

- Accessibility: Viewable on personal computers and laptops for on-the-go reference.

It is recommended that you use Adobe Acrobat Reader to ensure that all images and graphics display correctly for the best experience.

Why This Manual Is Essential

Utilizing this service manual allows you to:

- Perform Accurate Repairs: Follow detailed instructions to fix issues correctly the first time.

- Maintain Equipment Properly: Adhere to maintenance schedules to prevent breakdowns.

- Understand Technical Details: Access in-depth information on all equipment components.

- Troubleshoot Effectively: Use electrical schematics and troubleshooting guides to identify problems.

- Ensure Safety: Follow safe maintenance practices to protect yourself and others.

This manual is an invaluable tool for maintaining the performance and safety of your Clark EC500 60/80B equipment.

Need Additional Information?

If you have questions or need further details to enhance your understanding of the manual's content, please don't hesitate to contact our support team. We're here to assist you in making the most of this valuable resource.

![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](https://www.epcatalogs.com/file/base/7wCEvBLSdZwzQVInrh3OWQimnRBMYEUrrqpTXmOny0OE6JTuaHb8mc3MB9RffUXzWJnD5Esf2wGck3mbsCqCZ7ql9PGG5zYOq8W8tx67/clark-forklift-trucks-partsproplus-electronic-parts-catalog.png)