![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Claas Renault Axion 810 820 830 840 850 Tractor Service Manual PDF

[02/2008]This manual contains repair and technical service manuals, special repair instructions, operating instructions, wiring electrical diagrams, technical and troubleshooting information for Claas Renault Axion tractors.

Program contains helps you to diagnose and troubleshoot of Claas Renault Axion tractors, to solve any problems.

Electronic program is very simple and convenient. This information is presented in the format of PDF.

Software has a nice and friendly interface, the software after installing Adobe Reader, which allows you to find the necessary information to the user, as well as to print out individual pages or the entire text as a whole.

Workshop manual is a system of manuals for the owners of tractors Claas Renault Axion, and which contains the data to diagnose and troubleshoot computer system.

CONTENTS:

- A - ENGINE DPS TIER III

- A1 – GENERAL

- SPECIFIC TORQUE

- BLOCKING BETWEEN THE MOTOR OIL CASING/FRONT AXLE CHASSIS

- A2 – CYLINDER HEAD AND VALVES

- LOCAL MANUFACTURING TOOL

- INSPECTING VALVE BRIDGES

- INSPECTING THE ROCKER PIN

- INSPECTING THE ROCKERS

- MEASURING VALVE SHRINKAGE

- CYLINDER HEAD FLATNESS

- MEASURING CYLINDER HEAD THICKNESS

- VALVE GUIDE MEASUREMENT

- MEASURING THE VALVE SEAT BORE IN THE CYLINDER HEAD

- MEASURING THE VALVE SPRINGS

- MEASURING THE VALVES

- INSPECTING THE TURBOCHARGER

- CHECKING THE BELT TENSIONER SPRING

- REMOVING THE ALTERNATOR AND ALTERNATOR BRACKET

- REFITTING THE ALTERNATOR AND BRACKET

- REMOVING THE VISCOUC COUPLING

- REFITTING THE VISCOUS COUPLING

- REMOVING THE FAN HUB AND BRACKET

- REFITTING THE FAN HUB AND BRACKET

- REMOVING THE TURBOCHARGER

- REFITTING THE TURBOCHARGER

- REMOVING THE TURBOCHARGER ROD LINKAGE

- REFITTING THE TURBOCHARGER LINKAGE

- REMOVING THE EXHAUST MANIFOLD

- REFITTING THE EXHAUST MANIFOLD

- REMOVING THE COOLER AND DUCTS EGR

- REFITTING THE COOLER AND DUCTS EGR

- REMOVING THE THERMOSTAT COVER

- REFITTING THE THERMOSTAT COVER

- REMOVING THE THERMOSTAT MANIFOLD

- REFITTING THE THERMOSTAT COVER

- REMOVING THE CYLINDER HEAD COVER

- REFITTING THE CYLINDER HEAD COVER

- REMOVING THE ROCKER ARM ASSEMBLY

- REFITTING THE ROCKER SHAFT

- ADJUSTING THE VALVE ROCKERS

- REMOVING THE ROCKER CARRIER

- REFITTING THE ROCKER CARRIER

- REMOVING THE INJECTOR SOCKET

- REMOVING THE INJECTOR SOCKET

- REMOVING THE CYLINDER HEAD

- PREPARATION

- REFITTING THE CYLINDER HEAD

- REFITTING THE VALVE AND JOINT

- REFITTING THE VALVE AND GASKET

- REMOVING THE VALVE SEATS

- REFITTING THE VALVE SEATS

- REMOVING THE INTAKE MANIFOLD

- REFITTING THE INTAKE MANIFOLD

- REMOVING THE AIR DIFFUSER

- REFITTING THE AIR DIFFUSER

- REMOVING THE EGR VALVE

- REFITTING THE EGR VALVE

- A3 – LINERS, PISTONS AND CONNECTING RODS

- MEASURING THE COUNTERBORING DEPTH OF THE LINER FLANGE IN THE BLOCK

- MEASURING THE LINER FLANGE

- MEASURING FLATNESS OF THE PLATE AND THE PLATE/CRANKSHAFT BEARING DISTANCE

- MEASURING THE PISTON PIN BOREHOLE

- MEASURING THE PISTON SKIRT

- MEASURING THE PISTON HEIGHT

- MEASURING PISTON - LINER CLEARANCE

- INSPECTING AND MEASURING CONNECTING ROD BEARINGS

- INSPECTING THE CONNECTING ROD AND THE CAP

- INSPECTING THE PISTON PINS AND RINGS

- MEASURING THE BORE OF THE CONNECTING ROD PIN

- MEASURING THE CENTRE DISTANCE BETWEEN CONNECTING ROD BORES

- MEASURING THE PISTON OVERLAP

- DISMANTLING OF THE CONNECTING ROD/PISTON ASSEMBLY

- REMOVING THE PISTONS/CONNECTING RODS AND RINGS

- REMOVING THE PISOTN PIN BUSH

- DISASSEMBLING THE LINERS

- REMOVING THE CYLINDER BLOCK

- REFITTING THE CYLINDER BLOCK

- REFITTING THE LINERS

- REFITTING PISTON PIN RINGS

- REFITTING THE PISTONS/CONNECTING RODS AND PISTON RINGS

- REASSEMBLING PISTONS AND CONNECTING RODS

- A4 – FLYWHEEL, BEARING, AND CRANKSHAFT

- MEASURING THE INNER DIAMETER OF THE CRANKSHAFT JOURNALS AND BEARINGS

- MEASURING THE WIDTH OF JOURNALS AND THRUST BEARINGS

- CHECKING AXIAL CLEARANCE OF THE CRANKSHAFT

- REMOVING THE DAMPER PULLEY

- REFITTING THE DAMPER PULLEY

- REMOVING THE FRONT BEARING GASKET

- REFITTING THE FRONT BEARING SEAL

- REMOVING THE FLYWHEEL

- REFITTING THE FLYWHEEL

- REMOVING THE REAR BEARING GASKET

- REFITTING THE REAR BEARING GASKET

- REMOVING THE FLYWHEEL COVER

- REASSEMBLING THE ENGINE FLYWHEEL CASING

- REMOVING THE TIMING WHEEL

- REFITTING THE TIMING WHEEL

- REMOVING THE CRANKSHAFT PINION

- REFITTING THE CRANKSHAFT PINION

- REMOVING THE CRANKSHAFT BEARINGS AND THE CRANKSHAFT

- REFITTING THE CRANKSHAFT BEARINGS AND THE CRANKSHAF

- A5 – TIMING AND BALANCING SHAFT

- MEASURING THE BORE OF THE CAMSHAFT BUSH

- MEASURING AXIAL CLEARANCE OF THE CAMSHAFT

- MEASURING THE DIAMETER OF THE CAMSHAFT BUSH AND JOURNALS

- MEASURING THE CAM HEIGHT

- MEASURING AXIAL CLEARANCE OF THE IDLE GEAR

- MEASURING CLEARANCE BETWEEN THE TEETH OF THE TIMING GEARS

- DISASSEMBLY OF THE WATER PUMP

- DISASSEMBLY OF THE WATER PUMP

- REASSEMBLING THE WATER PUMP

- REFITTING THE WATER PUMP

- DISASSEMBLY OF THE DISTRIBUTOR CASING

- REFITTING THE PRESSURE REGULATOR

- REFITTING THE PRESSURE REGULATOR

- REMOVING THE CAMSHAFT AND WEAR BUSH

- REFITTING THE CAMSHAFT AND WEAR BUSH

- REMOVING THE FRONT PLATE

- REASSEMBLY OF THE FRONT PLATE

- INJECTION TIMING SETTING

- REFITTING THE TIMING COVER

- A6 – INJECTION ASSEMBLY

- REMOVING THE SUPPLY PUMP

- REFITTING THE SUPPLY PUMP

- REMOVING THE HIGH PRESSURE COMMON RAIL

- REFITTING THE HIGH PRESSURE COMMON RAIL

- REMOVING THE FLOW REGULATORS

- REFITTING THE FLOW REGULATORS

- REMOVING THE PRESSURE RESTRICTER

- REFITTING THE PRESSURE RESTRICTER

- REMOVING THE HIGH PRESSURE PUMP

- REFITTING THE HIGH PRESSURE PUMP

- REMOVING THE HIGH PRESSURE PUMP FILTER

- REFITTING THE HIGH PRESSURE PUMP FILTER

- REMOVING THE SOLENOID VALVE

- REFITTING THE SOLENOID VALVE

- REMOVING THE ELECTRONIC INJECTORS

- REFITTING ELECTRONIC INJECTORS

- A7 – LUBRICATION SYSTEM

- REMOVING THE OIL FILTER AND HOLDER

- REFITTING THE OIL FILTER AND HOLDER

- REMOVING THE OIL COOLER

- REFITTING THE OIL COOLER

- REMOVING THE ENGINE OIL PAN

- DISASSEMBLY OF THE OIL PUMP

- REASSEMBLING THE OIL PUMP

- REFITTING THE ENGINE OIL PAN

- B - GEARBOX

- B1 – GENERAL

- MAIN ADJUSTMENTS

- SPECIFIC TORQUES AND SEALING COMPOUNDS

- DISMANTLING PROCEDURE

- OPERATION OF CONTROL UNIT 60 05 006 155/ROBOT-DRIVEN RANGES

- B2 – HEXASHIFT

- LOCAL MANUFACTURING TOOL

- SUPPORT RODS OF THE HEXASHIFT AND REVERSHIFT CASING

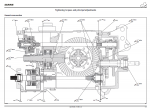

- EXPLODED VIEW

- REMOVING THE HEXASHIFT MODULE

- REMOVING THE “B228-2” ENGINE SPEED SENSOR(ON GEARBOX ENTRY SHAFT)

- REMOVING THE “HEXASHIFT” MODULE

- REFITTING THE “HEXASHIFT” MODULE

- ADJUSTING THE “B228-2” ENGINE SPEED SENSOR WITH TRACTOR UNCOUPLED

- REFITTING THE “B228-2” ENGINE SPEED SENSOR

- B3 – “REVERSHIFT”

- LOCALLY MADE TOOL

- ELASTIC WASHER COMPRESSOR ON FORWARD CLUTCH

- EXPLODED VIEW

- REMOVING THE “REVERSHIFT” MODULE

- REMOVING THE REVERSE CLUTCH

- DÉREMOVING THE FORWARD CLUTCH

- REFITTING THE “REVERSHIFT” MODULE

- REFITTING THE CLUTCH (FORWARD GEAR)

- REFITTING THE CLUTCH (REVERSE GEAR)

- REFITTING THE “REVERSHIFT” MODULEREPOSE DU MODULE

- ACCESS TO FORWARD CLUTCH WITHOUT REMOVAL

- B4 – ROBOT-DRIVEN RANGES

- LOCALLY MADE TOOL

- SUPPORT RODS OF THE ROBOT-DRIVEN RANGES MODULE

- PNEUMATIC FITTING (FOR SUPPLY OF THE ROBOT-DRIVEN RANGES CIRCUIT)

- ROD FOR DIMENSIONING THE REVERSE GEAR

- EXPLODED VIEW

- REMOVING THE RANGES MODULE

- REMOVING THE PRIMARY AND SECONDARY LINES

- REMOVING THE PRIMARY LINE

- SHIMMING OF TAPERED ROLLER BEARINGS

- SYNCHRONISER COVER ADJUSTMENT

- REFITTING THE PRIMARY LINE

- REMOVING THE SECONDARY LINE

- REFITTING THE SECONDARY LINE

- SHIMMING OF TAPERED ROLLER BEARINGS

- ADJUSTING THE SHAFTS IN THE HOUSING

- MEASURING SHAFT CLEARANCE IN THE CASING

- REFITTING THE RANGES MODULE

- ADJUSTING THE STOP NUTS OF THE RANGES MODULE

- ADJUSTING THE RANGES MODULE BANNING LOCK

- REFITTING THE RANGES MODULE

- B5 – 4 WHEEL DRIVE SHAFT

- LOCALLY MADE TOOL

- GUIDE OF THE 4 WHEEL DRIVE SHAFT

- PREPARATION

- EXPLODED VIEW

- REMOVING THE 4 WHEEL DRIVE SHAFT

- REFITTING THE 4 WHEEL DRIVE SHAFT

- PROCEDURE FOR SHIMMING THE 4 WHEEL DRIVE SHAFT

- REFITTING THE 4 WHEEL DRIVE SHAFT

- B6 – SLOW RANGE

- EXPLODED VIEW

- REMOVING THE SLOW RANGE

- REMOVING THE REDUCER ASSEMBLY

- REFITTING THE REDUCER ASSEMBLY

- REFITTING THE SLOW RANGE

- ADJUSTING THE ACTUATION DEVICE

- ADJUSTING THE SLOW RANGE LEVER

- C1 - GENERAL

- TIGHTENING TORQUES AND PRINCIPAL ADJUSTMENTS

- GENERAL CROSS-SECTION

- "ND" AXLE TUBES

- "HD" AXLE TUBES

- "HDE" AXLE TUBES

- COMPOSITE AXLE TUBES

- GEARBOX/REAR AXLE COUPLING

- REAR AXLE/PTO HOUSING COUPLING

- LOCAL MANUFACTURING TOOL

- REAR POWER TAKE-OFF TOOLS

- SERVICE BRAKE TOOLS

- C2 -DRIVE PINION

- GPA 40 DRIVE PINION

- GENERAL

- EXPLODED VIEW

- REMOVAL/REFITTING

- SETTING AND ADJUSTING THE PROTRUSION DISTANCE OF THE DRIVE PINION

- C3 - DIFFERENTIAL

- GENERAL

- EXPLODED VIEW

- REMOVING/REFITTING THE BEARINGS

- REMOVING/REFITTING THE DIFFERENTIAL HOUSING

- REMOVING/REFITTING THE DIFFERENTIAL LOCK

- REMOVING/REFITTING THE PLANET GEARS, SUN GEARS AND RING GEAR

- ADJUSTING THE BACKLASH

- SHIMMING THE DIFFERENTIAL CASE ROLLER BEARINGS

- C4 - REAR POWER TAKE-OFF

- POWER TAKE-OFF CLUTCH

- REAR POWER TAKE-OFF UPPER SHAFT

- REAR POWER TAKE-OFF LOWER SHAFT

- PROPORTIONAL PTO

- C5 - AUTOMATIC BRAKE

- EXPLODED VIEW OF THE AUTOMATIC BRAKE ACTUATION UNIT EXPLODED VIEW OF BRAKE MECHANISM

- REMOVING/REFITTING THE ACTUATION UNIT

- REMOVING/REFITTING THE PARKING BRAKE

- REMOVAL/REFITTING OF BRAKE MECHANISM

- REMOVING/REFITTING THE ACTUATION UNIT

- BASIC PARKING BRAKE ADJUSTMENT

- ADJUSTING THE PARKING BRAKE CONTROL

- C6 - SERVICE BRAKE 40 AND 50 KM/H

- BRAKE PISTONS AND SEALS

- REPLACING THE MASTER CYLINDERS

- ADJUSTMENT OF THE BRAKE PEDALS

- BLEEDING THE BRAKE CIRCUIT

- C7 – AXLE TUBES

- "ND" AXLE TUBES

- "HD" AXLE TUBES

- "HDE" AXLE TUBES

- COMPOSITE AXLE TUBES

- D - SUSPENDED FRONT AXLE

- D1 – GENERAL

- SPECIFIC TORQUES AND SEALING PRODUCTS FOR THE JOINT BOX

- SPECIFIC TORQUE AND SEALING PRODUCTS FOR THE SUSPENSION

- SPECIFIC TORQUE AD SEALING PRODUCTS OF THE BEVEL GEAR

- SPECIFIC TORQUE AND SEALING PRODUCTS OF THE DIFFERENTIAL

- SPECIFIC TORQUE AD SEALING PRODUCTS OF THE BEVEL GEAR

- SPECIFIC TORQUE AND SEALING PRODUCTS OF THE EPICYCLICAL REDUCER

- REMOVING THE FRONT AXLE

- REFITTING THE FRONT AXLE

- D2 – EPICYCLOID REDUCER

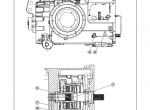

- EXPLODED VIEW OF THE EPIXYXLIX REDUCER

- PREPARATION

- REMOVING THE EPICYCLIC REDUCER

- REFITTING THE EPICYCLIC REDUCER

- D3 – JOINT UNIT

- EXPLODED VIEW

- PREPARATION TO REMOVING THE JOINT BOX

- REMOVING THE JOINT BOX

- DISMANTLING

- REFITTING

- REFIT THE JOINT BOX

- ADJUSTMENT

- D4 – SUSPENSION

- EXPLODED VIEW OF THE SUSPENSION

- REMOVING THE SUSPENSION

- REFITTING THE SUSPENSION

- SHIMMING THE SUSPENSION

- D5 – CROWN WHEEL AND PINION AND DIFFERENTIAL

- LOCAL MANUFACTURING TOOL

- EXPLODED VIEW OF THE BEVEL GEAR

- EXPLODED VIEW OF DIFFERENTIAL

- PREPARATION

- REMOVING THE CASING

- DIFFERENTIAL REMOVAL

- REMOVING THE DRIVE PINION

- REFITTING THE DRIVE PINION

- DISMANTLING THE DIFFERENTIAL

- INSTALLING THE DIFFERENTIAL

- REFITTING THE DIFFERENTIAL

- REFITTING THE CASING

- D6 – 4WD POWER TAKE-OFF HOUSING

- GENERAL

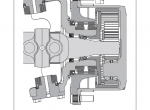

- CROSS-SECTION OF THE 4-WHEEL DRIVE HOUSING

- CROSS-SECTION OF THE 4-WHEEL DRIVE HOUSING

- EXPLODED VIEW OF THE 4-WHEEL DRIVE HOUSING

- REMOVING THE 4-WHEEL DRIVE CLUTCH

- REMOVING THE CLUTCH

- REFITTING THE CLUTCH

- FITTING SHIMS TO THE CLUTCH "J1"

- FITTING SHIMS TO THE SHAFT "J2"

- REFITTING THE SHAFT

- COUPLING THE REAR AXLE/GEARBOX

- E1 – GENERAL

- SPECIFIC TORQUES AND SEALING COMPOUNDS

- E2 – HYDRAULIC SOURCE

- DESCRIPTION

- LOCATION OF COMPONENTS ON LEFT AND RIGHT SIDE COVER

- EXPLODED VIEW OF LEFT AND RIGHT SIDE COVER

- INTERNAL VIEW OF THE LEFT-HAND COVER

- SECTIONAL VIEW OF THE LEFT-HAND COVER

- LOCATION OF THE COMPONENTS ON THE PRIORITY BLOCK

- IDENTIFICATION OF HOLES AND PIPES ON RIGHT COVER

- REMOVING THE PRIORITY BLOCK

- REMOVAL OF RIGHT COVER

- REMOVING THE VARIABLE DISPLACEMENT PUMP

- REFITTING THE VARIABLE DISPLACEMENT PUMP

- REPLACING THE RH COVER

- REFITTING THE PRIORITY BLOCK

- REMOVING THE LEFT-HAND COVER

- REFITTING THE LEFT-HAND COVER

- REMOVING THE BOOSTER PUMP

- REFITTING THE BOOSTER PUMP

- REPLACEMENT OF PUMP SEALS

- E3 – REAR LIFT

- LOCATION OF COMPONENTS ON REAR LIFTING

- EXPLODED VIEW OF LINKAGE SPOOL VALVE

- REMOVING THE LIFTING VALVE

- REFIT THE LINKAGE SPOOL VALVE

- REMOVING THE LIFTING JACK

- DISMANTLING THE LINKAGE ACTUATOR

- REFITTING THE LINKAGE ACTUATOR

- REFITTING THE LIFTING JAC

- E4 – ELECTROHYDRAULIC SPOOL VALVE ("DEH")

- EXPLODED VIEW OF AN ELECTROHYDRAULIC COMMAND AUXILIARY SPOOL VALVE

- REMOVING THE SPOOL VALVE BLOCK

- REFITTING THE SPOOL VALVE UNIT

- CHANGING THE GASKETS BETWEEN SPOOL VALVES

- CHANGING THE ELECTRIC CONTROL BLOCK OF A SPOOL VALVE

- REMOVING THE VALVE SPOOL

- REFITTING THE VALVE SPOOL

- REMOVING THE VALVE SPOOL AND FLOW REGULATOR

- REFITTING THE VALVE SPOOL AND FLOW REGULATOR

- E5 – STEERING

- EXPLODED VIEW OF THE STEERING UNIT

- EXPLODED VIEW OF THE STEERING ACTUATOR

- REMOVE THE STEERING UNIT

- OVERHAULING THE STEERING UNIT

- REFITTING THE STEERING UNIT

- PREPARATION FOR OVERHAULING THE STEERING ACTUATOR

- REMOVE THE STEERING ACTUATOR

- REMOVING THE STEERING ACTUATOR

- REFITTING THE STEERING ACTUATOR

- F - ELECTRICAL SERVICES

- F1 - FUNCTION DIAGRAMS

- WORK LIGHTS

- ROAD SIGNALLING

- VENTILATION AND A/C

- LINKAGE

- PTO

- STARTING AND LOADING CIRCUIT

- TRANSMISSION

- ACCESSORIES

- WIPER/WASHER

- DEFROSTING

- REAR VIEW MIRRORS

- NETWORKS

- SUPPLY

- TRACTOR/TOOL LINK

- BRAKE SYSTEM

- SEAT

- RADAR

- TRANSMISSION SPEED

- SUSPENSION

- LEVELS

- ENGINE

- INSTRUMENT PANEL

- ELECTROHYDRAULIC SPOOL VALVES

- AUTOMATION

- F2 – ELECTRICAL SYSTEM

- F3 – IMPLANTATION DIAGRAMS

- 01 - Cab bottom harness

- 02 - Instrument panel harness

- 03 - Fender harness

- 04 - Cab top harness

- 05 - Under cab harness

- 06 - Suspended front axle harness

- 07 - Cab supply harness

- 08 - Internal transmission harness

- 09 - Transmission harness

- 10 - Engine harness

- 11 - Radiator cowling harness

- 12 - Electronic injection harness

- 13 - Transmission control harness

- 14 - Command harness REH

- 15 - Harness REH

- 16 - Harness UBM

- 17 - Front lifting and PTO harness

- 18 - Rear work light harness

- 19 - Railing harness

- 20 - Right console harness

- 21 - Police plate lighting harness

- 22 - High/low low beam switching harness

- 24 - Automatic handbrake harness

- 25 - Braking harness

- 26 - Rotating lights harness

- 27 - Internal supply harness

- 50 - Extension of front lifting and power take-off harness

- 53 - Radar adapter

- C1 - Supply cable PSP

- C2 - Short-circuit cable

- C3 - Cable of positive launch before contact

- C4 - Cable of positive launch under contact

- C5 - Ground cable

- C6 - Negative launch cable

- C7 - Preheating cable

- G1 - LIST OF ERROR CODES

- "CEBIS" PANEL (MFT A30)

- LIST OF ERROR CODES

- G2 - CONTROL PANEL "WLP"

- GENERAL DESCRIPTION

- WORKING LIGHTS

- CAB LIGHTING

- ROTATING BEACONS

- DEFROSTING

- H - CAB

- H1 – CAB LIFT

- SAFETY

- REMOVING THE CAB

- REFITTING THE CAB

- H2 – HEATING/AIR CONDITIONING

- CAPACITIES

- REMOVING THE COMPRESSOR

- REFITTING THE COMPRESSOR

- REMOVING THE DEHYDRATOR FILTER

- REFITTING THE DEHYDRATOR FILTER

- REMOVAL OF THE CONDENSER

- REFITTING THE CONDENSER

- REMOVAL OF THE EXPANSION VALVE

- REFITTING THE PRESSURE REGULATOR

- REMOVING THE MOTOR FAN

- REFITTING THE MOTOR FAN

- REMOVING THE HEATING/AIR CONITIONING UNIT

- REFITTING THE HEATING/AC UNIT

- REMOVING THE EVAPORATOR AND HEATING RADIATOR

- REFITTING THE EVAPORATOR AND HEATING RADIATOR

- J1 - FRONT LINKAGE

- GENERAL DESCRIPTION

- MECHANICAL PART

- HYDRAULIC PART

- ELECTRONIC COMPONENTS

- J2 - FRONT POWER TAKE-OFF

- GENERAL DESCRIPTION

- ELECTRONIC COMPONENTS

- MECHANICAL PART

- HYDRAULIC PILOTING PART

- RESULTS RECORD FORM

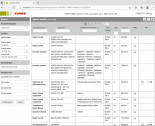

Screenshots for Claas Renault Axion 810 820 830 840 850 Tractor Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Claas Renault Axion 810 820 830 840 850 Tractor Service Manual PDF:

![spare parts catalog CLAAS Parts Doc Offline Update v919 [02.2026]](/imgs/type_zapch.gif)

CLAAS Parts Doc Offline Update v919 [02.2026]![spare parts catalog CLAAS Parts Doc Offline Update v919 [02.2026]](https://www.epcatalogs.com/file/base/7wCEvBLSdZwzQV0mrB3OWQimnRBfeEUrrqpTXj6xyw3ZttGvdD6hzIPdGd5SYFSxRpHSvUhTyhSb33aVo2WeZrr386LQrnRP8s24+UD651Y+8g==/claas-doc-2.1-parts-catalog-2018.png)

The Claas parts catalog 02/2026 Upd 915 features step-by-step service procedures, repair illustrations, detailed wiring diagrams, and manufacturer specifications and are easy to follow.

200$

[02/2026]

|

CLAAS WebTIC Offline 07.2025 Service Information Database

Claas WebTIC 07/2025 is a Windows desktop offline workshop service and repair manuals database, the best research service for your Claas equipment.

250$

[07/2025]

|

Claas CDS CANUSB Interface Activation Key

The CLAAS activation key is needed to activate the Claas diagnostic interface when the CDS application is run on the machine for the first time.

50$

[2025]

|

Claas Parts DOC v.2.0. (Agricultural)

New program Claas Parts DOC v.2.0. (Agricultural) is a catalog of spare parts and accessories for all models of agricultural machinery Claas.

100$

[08/2012]

|