![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Claas Renault Ares 507 607 Service Repair Manual PDF

[06/2005]This workshop manual provides guidance on repair, operating instructions, installation instructions, maintenance and troubleshooting information, designed to serve Claas Renault Ares 507, 607.

Service manual contains detailed drawings and diagrams that help you to get a detailed description of repair and maintenance procedures, using which the user can determine the installation location, etc.

Service Manual comes in PDF and includes 1599 pages, which are printable & readable. To view the information you want the program installed Adobe Reader.

Online repair manual helps you to fast and simple calibrate and serve technique Claas Renault Ares, diagnose it, and troubleshoot and solve any problems that arise, to find information about the equipment.

CONTENTS:

- A1 – INJECTION SHEET CHECKING PROCEDURE

- CHECKING PROCEDURE

- MEASUREMENT AND CHECKING POINTS

- APPENDIX

- A2 – DE 10 INJECTION

- DESCRIPTION

- DESCRIPTION AND OPERATION

- ADDITIONAL TECHNICAL DETAILS

- TIGHTENING TORQUES

- FILTER ELEMENT

- INJECTOR PUMP

- INJECTOR

- ELECTRONIC CONTROL

- MANIFOLD AIR TEMPERATURE SENSOR

- ENGINE COOLANT TEMPERATURE SENSOR

- FUEL TEMPERATURE SENSOR

- CRANKSHAFT POSITION SENSOR

- PUMP CONTROL SOLENOID

- ACCELERATOR DETECTOR

- A3 – ENGINE TIER II

- GENERAL DESCRIPTION

- TECHNOLOGY OF NON-MOVING PARTS

- TECHNOLOGY OF MOVING PARTS

- LUBRICATION

- COOLING

- AIR

- TIGHTENING TORQUES

- DIMENSIONAL SPECIFICATIONS

- CHECK

- REMOVAL/REFITTING

- DIAGNOSTIC SHEETS

- B1 – MECHANICAL PART

- GENERAL DESCRIPTION

- "HEXASHIFT" MODULE

- REVERTER MODULE UNDER TORQUE

- ROBOT-DRIVEN RANGES MODULE

- CRAWLER RANGES MODULES

- CHARACTERISTICS GBA 25

- DISMANTLING PROCEDURE

- MAIN ADJUSTMENTS

- TORQUE SETTINGS AND SEALANTS

- "HEXASHIFT" MODULE

- REVERTER MODULE UNDER TORQUE

- ROBOT-DRIVEN RANGES MODULE

- SLOW RANGE

- EXTRA SLOW RANGE

- B2 – HYDRAULIC PART

- LOW PRESSURE CIRCUIT 20 BAR

- LOW PRESSURE LUBRICATION CIRCUIT

- CHARACTERISTICS OF LOW PRESSURE CIRCUITS

- OPEN CENTER 60 L/MIN

- "LOAD SENSING" 100 L/MIN

- CONTROL CIRCUIT TIGHTENING TORQUES

- SOLENOID VALVE MEASUREMENT AND CHECKING POINTS

- CONTROL UNIT GBA 25 MEASURING AND CHECKING POINTS

- GBA 25 "HYDRAULIC INSPECTION RESULTS" SHEET

- 60 L/MIN OPEN CENTRE MEASUREMENT AND CHECKING POINTS

- 60 L/MIN OPEN CENTRE "INSPECTION RESULTS" SHEET

- "LOAD SENSING" 100 L/MIN MEASURING AND CHECKING POINTS

- "LOAD SENSING" 100 L/MIN "INSPECTION RESULTS" SHEET

- "LOAD SENSING" 110 L/MIN MEASURING AND CHECKING POINTS

- "LOAD SENSING" 110 L/MIN "INSPECTION RESULTS" SHEET

- B3 – ELECTRONIC COMPONENTS

- ELECTRONIC TRANSMISSION CONTROL

- GEARBOX ELECTRONIC CONTROL

- COMPONENT LAYOUT

- ELECTRICAL TESTS

- ADJUSTMENTS AND CALIBRATION

- "SPEED AND SAFETY" MEASUREMENT AND CHECKING POINTS

- "SUPPLY" MEASUREMENT AND CHECKING POINTS

- "HEXASHIFT" MEASUREMENT AND CHECKING POINTS

- "ROBOT-DRIVEN RANGE" MEASUREMENT AND CHECKING POINTS

- "SHUTTLE REVERSER" MEASUREMENT AND CHECKING POINTS

- "MODE MANAGEMENT" MEASUREMENT AND CHECKING POINTS

- "OVERDRIVE" MEASUREMENT AND CHECKING POINTS

- "SLOW" MEASUREMENT AND CHECKING POINTS

- "DISPLAY" MEASURING AND CHECKING POINTS

- C1 – MECHANICAL PART

- PRESENTATION OF THE REAR AXLE

- TIGHTENING TORQUES AND PRINCIPAL ADJUSTMENTS

- "HD" AXLE TUBE

- "SHD" AXLE TUBE

- CROWN WHEEL AND PINION AND DIFFERENTIAL

- REAR POWER TAKE OFF CLUTCH

- REAR POWER TAKE-OFF UPPER SHAFT

- REAR POWER TAKE-OFF LOWER SHAFT

- POWER TAKE-OFF SENSOR AND CONTROL

- PROPORTIONAL PTO

- TRANSIMISSION SERVICE BRAKE 40 KM/H

- TRANSIMISSION SERVICE BRAKE 50 KM/H

- TRANSMISSION HAND BRAKE 40 KM/H

- TRANSMISSION HAND BRAKE 50 KM/H

- C2 – HYDRAULIC PART

- LOW PRESSURE CIRCUIT 20 BAR

- BRAKING 40 KM/H

- BRAKING 50 KM/H

- LUBRICATION SYSTEM

- OPEN CENTER 60 L/MIN

- "LOAD SENSING" 100 L/MIN

- TORQUE SETTINGS

- 60 L/MIN OPEN CENTRE MEASUREMENT AND CHECKING POINTS

- 60 L/MIN OPEN CENTRE "INSPECTION RESULTS" SHEET

- "LOAD SENSING" 100 L/MIN MEASURING AND CHECKING POINTS

- "LOAD SENSING" 100 L/MIN "INSPECTION RESULTS" SHEET

- "LOAD SENSING" 110 L/MIN MEASURING AND CHECKING POINTS

- "LOAD SENSING" 110 L/MIN "INSPECTION RESULTS" SHEET

- TRANSMISSION BRAKING CIRCUIT (40 KM/H VERSION)

- TRANSMISSION BRAKING CIRCUIT (50 KM/H VERSION)

- C3 – ELECTRONIC COMPONENTS

- ELECTRONIC REAR AXLE CONTROL

- COMPONENT LAYOUT

- ELECTRICAL TESTS

- "LOW PRESSURE HYDRAULIC SYSYTEM" MEASUREMENT AND CHECKING POINTS

- "ENGINE SPEED" MEASUREMENT AND CHECKING POINTS

- "SUPPLY" MEASUREMENT AND CHECKING POINTS

- "4-WHEEL DRIVE UNIT" MEASUREMENT AND CHECKING POINTS

- "DIFFERENTIAL LOCK" MEASUREMENT AND CHECKING POINTS

- "POWER TAKE-OFF" MEASUREMENT AND CHECKING POINTS

- "BRAKING" MEASUREMENT AND CHECKING POINTS

- D1 – MECHANICAL PART

- GENERAL

- MAIN TORQUES

- WHEEL ALIGNMENT

- PRELIMINARY OPERATIONS

- STEERING CYLINDER

- EPICYCLIC REDUCTION GEAR AND WHEEL HUB

- WHEEL SWIVEL PIN

- BEVEL GEAR AND DIFFERENTIAL

- 4 WHEEL DRIVE UNIT

- D2 – HYDRAULIC PART

- OPERATION

- MEASUREMENT AND CHECKING POINTS

- "INSPECTION RESULTS" SHEET

- D3 – ELECTRONIC PART

- FRONT AXLE

- 4 WHEEL DRIVE UNIT

- E1 – COMMON ELEMENTS

- PRESENTATION OF LINKAGE

- LINKAGE OPERATION

- "SNR" BRAKE VALVE OPERATION

- "CUNA" BRAKE VALVE OPERATION

- STEERING UNIT

- AUXILIARY SPOOL VALVE

- LINKAGE

- BRAKING VALVE

- E2 – OPEN CENTER 60 L/MIN

- DESCRIPTION

- COMPONENT LAYOUT

- RH COVER

- LH COVER

- HYDRAULIC MEASUREMENT AND CHECKING POINTS

- MEASUREMENT AND CHECKING POINTS

- "HYDRAULIC INSPECTION RESULTS" SHEET

- HYDRAULIC MEASUREMENT AND CHECKING POINTS

- "HYDRAULIC INSPECTION RESULTS" SHEET

- E3 – "LOAD SENSING" 100 L/MIN

- DESCRIPTION

- COMPONENT LAYOUT

- RH COVER

- LH COVER

- CIRCUIT SELECTOR

- HYDRAULIC MEASUREMENT AND CHECKING POINTS

- "HYDRAULIC INSPECTION RESULTS" SHEET

- HYDRAULIC MEASUREMENT AND CHECKING POINTS

- "HYDRAULIC INSPECTION RESULTS" SHEET

- E4 – "LOAD SENSING" 110 L/MIN

- DESCRIPTION

- OPERATION

- COMPONENT LAYOUT

- PRIORITY UNIT

- RH COVER

- LH COVER

- BOOSTER PUMP

- HYDRAULIC MEASUREMENT AND CHECKING POINTS

- "HYDRAULIC INSPECTION RESULTS" SHEET

- G1 – INSTRUMENT PANEL

- DESCRIPTION

- CHARACTERISTICS

- REMOVAL/REFITTING

- CONNECTORS "JX1" AND "JX2"

- ADJUSTMENTS

- G2 – TCE 15 T ELECTRONIC LIFT

- DESCRIPTION

- CHECKS AND ADJUSTMENTS

- G3 – TCE 15/25 ELECTRONIC LIFT

- DESCRIPTION

- CHECKS AND ADJUSTMENTS

- G4 – INFOTRAC AND ISO SOCKET

- PRESENTATION OF THE "INFOTRAC"

- PRESENTATION OF THE ISO SOCKET

- REMOVAL/REFITTING AND ELECTRICAL CHECKS

- ADJUSTMENTS

- G5 – ELECTROPILOT

- DESCRIPTION

- SPOOL VALVES

- ELECTROHYDRAULIC SPOOL VALVE ("DEH")

- ADDITIONAL TECHNICAL DETAILS

- REMOVAL/REFITTING

- CHECK

- MEASUREMENT AND CHECKING POINTS

- "INSPECTION RESULTS" SHEET

- H1 – CAB LIFTING AND GLASS BONDING

- DESCRIPTION

- REMOVING THE CAB

- REFITTING THE CAB

- REMOVAL/REFITTING OF GLAZING

- H2 – MANUAL HEATING/AIR CONDITIONING

- CHARACTERISTICS

- GENERAL DESCRIPTION

- POSITIONING OF COMPONENTS

- DESCRIPTION AND OPERATION

- SAFETY INSTRUCTIONS

- GAS CHARGING AND DISCHARGING

- REMOVAL/REFITTING

- DIAGNOSTICS

- H3 – REGULATED HEATING AND A/C

- CLIMATE CONTROL

- J1 – LIFT AND FRONT POWER TAKE-OFF

- FRONT LINKAGE

- MEASUREMENT AND CHECKING POINTS

- "INSPECTION RESULTS" SHEET

- FRONT POWER TAKE-OFF

- MEASUREMENT AND CHECKING POINTS

- "INSPECTION RESULTS" SHEET

- J2 – PNEUMATIC BRAKING

- HOW IT WORKS

- MAIN COMPONENTS

- TOOLS

- J3 – PNEUMATIC BRAKE

- GENERAL DESCRIPTION

- PRESENTATION OF THE DIFFERENT SYSTEMS

- TECHNOLOGICAL CONCEPTS

- DESCRIPTION

- OPERATING PRINCIPLE

- TORQUE SETTINGS AND SEALANTS

- MEASUREMENT AND CHECKING POINTS

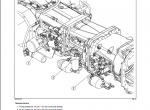

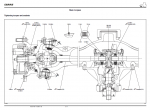

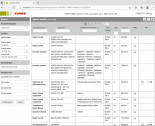

Screenshots for Claas Renault Ares 507 607 Service Repair Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Claas Renault Ares 507 607 Service Repair Manual PDF:

![spare parts catalog CLAAS Parts Doc Offline Update v919 [02.2026]](/imgs/type_zapch.gif)

CLAAS Parts Doc Offline Update v919 [02.2026]![spare parts catalog CLAAS Parts Doc Offline Update v919 [02.2026]](https://www.epcatalogs.com/file/base/7wCEvBLSdZwzQV0mrB3OWQimnRBfeEUrrqpTXj6xyw3ZttGvdD6hzIPdGd5SYFSxRpHSvUhTyhSb33aVo2WeZrr386LQrnRP8s24+UD651Y+8g==/claas-doc-2.1-parts-catalog-2018.png)

The Claas parts catalog 02/2026 Upd 915 features step-by-step service procedures, repair illustrations, detailed wiring diagrams, and manufacturer specifications and are easy to follow.

200$

[02/2026]

|

CLAAS WebTIC Offline 07.2025 Service Information Database

Claas WebTIC 07/2025 is a Windows desktop offline workshop service and repair manuals database, the best research service for your Claas equipment.

250$

[07/2025]

|

Claas CDS CANUSB Interface Activation Key

The CLAAS activation key is needed to activate the Claas diagnostic interface when the CDS application is run on the machine for the first time.

50$

[2025]

|

Claas Parts DOC v.2.0. (Agricultural)

New program Claas Parts DOC v.2.0. (Agricultural) is a catalog of spare parts and accessories for all models of agricultural machinery Claas.

100$

[08/2012]

|