![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Caterpillar Telehandler TH255, TH255C Axle Service Manual PDF

[09/2014]This PDF Service Manual provides general directions for accomplishing service and repair procedures of the Caterpillar Telehandlers TH255, TH255C Models. Following the procedures in this manual will help assure safety and equipment reliability.

The efficiency and continued operation of mechanical units depend on constant, correct maintenance and also on efficient repair work, should there be a break-down or malfunction. The instructions contained in this manual have been based on a complete overhaul of the unit. However, it is up to the mechanic to decide whether or not it is necessary to assemble only individual components when partial repair work is needed. The manual provides a quick and sure guide which, with the use of photographs and diagrams illustrating the various phases of the operations, allows accurate work to be performed.

You can study this pdf manual using screenshots and a list of content, which is presented in the manual description. You can also follow the link 'Caterpillar pdf manual instant preview', and preview the pages of this manual.

You are buying a factory service manual for Caterpillar Telehandlers. After your purchase, within 3-5 minutes we send to your email address the link for download with all necessary recommendations. If you want the same factory information shipped to you on a DVD please pay the Shipping charge during checkout or write to us about it.

Serial numbers:

SN TBS00100 to Present

SN JK200150 to Present

SN JK300150 to Present

Contents:

- Section 1 - Safety Practices

- 1.1 Introduction

- 1.2 Disclaimer

- 1.3 Operation & Maintenance Manual

- 1.4 Do Not Operate Tags

- 1.5 Safety Information

- 1.6 Safety Alert System and Signal Words

- 1.7 Safety Instructions

- 1.8 Safety Decals

- Section 2 - General Information and Specifications

- 2.1 Introduction

- 2.2 Specifications

- 2.3 Conversion Tables

- 2.4 Torque Specifications

- 2.5 Maintenance

- 2.6 Safety Precautions

- Section 3 - Planetary Reduction 1:6 and Steering Case

- 3.1 Exploded View

- 3.2 Planetary Reduction - 1.6 and Steering Case - Disassembly

- 3.3 Planetary Reduction - 1.6 and Steering Case - Assembly

- Section 4 - Steering Cylinder

- 4.1 Exploded View

- 4.2 Steering Cylinder - Disassembly

- 4.3 Steering Cylinder - Assembly

- Section 5 - Brake: Service Brake, Negative Brake, 45% Locked & 100% Locked

- 5.1 Exploded View

- 5.2 Brake Working Conditions

- 5.3 Emergency Release Instructions

- 5.4 Reset of Fails Safe Brake Function

- 5.5 Brake: Service Brake, Negative Brake, 45% Locked & 100% Locked- Disassembly

- 5.6 Brake: Service Brake, Negative Brake, 45% Locked & 100% Locked - Assembly

- 5.7 Brake Piston Gap Check

- Section 6 - Brake: Negative Brake 4 Cup Springs Version

- 6.1 Exploded View

- 6.2 Brake: Negative Brake 4 Cup Springs Version - Disassembly

- 6.3 Brake: Negative Brake 4 Cup Springs Version - Assembly

- Section 7 - Normal Preloaded Differential Unit (Old Version)

- 7.1 Exploded View

- 7.2 Normal Preloaded Differential Unit (Old Version) - Disassembly

- 7.3 Normal Preloaded Differential Unit (Old Version) - Assembly

- Section 8 - Normal Preloaded Differential Unit (Intermediate Version)

- 8.1 Exploded View

- 8.2 Normal Preloaded Differential Unit (Intermediate Version) - Disassembly

- 8.3 Normal Preloaded Differential Unit (Intermediate Version) - Assembly

- Section 9 - Normal Preloaded Differential Unit (Last Version)

- 9.1 Exploded View

- 9.2 Normal Preloaded Differential Unit (Last Version) - Disassembly

- 9.3 Normal Preloaded Differential Unit (Last Version) - Assembly

- Section 10 - Flanged Reduction Gear 603 Type: Integral 603 Input Gear

- 10.1 Exploded View

- 10.2 Flanged Reduction Gear 603 Type: Integral 603 Input Gear - Disassembly

- 10.3 Flanged Reduction Gear 603 Type: Integral 603 Input Gear - Assembly

- Section 11 - Bevel Pinion: Normal Flange and Nut Revolution Counter Version

- 11.1 Exploded View

- 11.2 Bevel Pinion: Normal Flange and Nut Revolution Counter Version- Disassembly

- 11.3 Bevel Pinion: Normal Flange and Nut Revolution Counter Version - Assembly

- Section 12 - Ring and Pinion Adjusting: Step for Preloaded Differential

- 12.1 Exploded View

- 12.2 Ring and Pinion Adjusting: Step for Preloaded Differential - Install and Adjust

- Section 13 - Swinging Support

- 13.1 Exploded View

- 13.2 Swinging Support - Disassembly

- 13.3 Swinging Support - Assembly

- Section 14 - Planetary Reduction: 1:4, 23

- 14.1 Exploded View

- 14.2 Planetary Reduction: 1:4, 23 - Disassembly

- 14.3 Planetary Reduction: 1:4, 23 - Assembly

- Section 15 - Brake: Incoming Disc Brake

- 15.1 Exploded View

- 15.2 Brake: Incoming Disc Brake - Disassembly

- 15.3 Brake: Incoming Disc Brake - Assembly

- 15.4 Checking Wear and Replacing the Braking Pads

- Section 16 - Brake: Service and Mechanical Parking Brake

- 16.1 Exploded View

- 16.2 Brake: Incoming Disc Brake - Disassembly

- 16.3 Brake: Incoming Disc Brake - Assembly

- Section 17 - Brake: Parking Brake and Differential Hydraulic 100%

- 17.1 Exploded View

- 17.2 Brake: Incoming Disc Brake- Disassembly

- 17.3 Brake: Incoming Disc Brake- Assembly

- Section 18 - Differential With Block to Spheres 100% (Old Version)

- 18.1 Exploded View

- 18.2 Differential With Block to Spheres 100% (Old Version) - Disassembly

- 18.3 Differential With Block to Spheres 100% (Old Version) - Assembly

- Section 19 - Differential With Block to Spheres 100% (Last Version)

- 19.1 Exploded View

- 19.2 Differential With Block to Spheres 100% (Last Version)- Disassembly

- 19.3 Differential With Block to Spheres 100% (Last Version)- Assembly

- Section 20 - Normal Differential (Old Version)

- 20.1 Exploded View

- 20.2 Normal Differential (Old Version) - Disassembly

- 20.3 Normal Differential (Old Version) - Assembly

- Section 21 - Normal Differential (Last Version)

- 21.1 Exploded View

- 21.2 Normal Differential (Last Version) - Disassembly

- 21.3 Normal Differential (Last Version) - Assembly

- Section 22 - Limited Slip Differential Unit 45% (Old Version)

- 22.1 Exploded View

- 22.2 Limited Slip Differential Unit 45% (Old Version) - Disassembly

- 22.3 Limited Slip Differential Unit 45% (Old Version) - Assembly

- Section 23 - Limited Slip Differential Unit 45% (Last Version)

- 23.1 Exploded View

- 23.2 Limited Slip Differential Unit 45% (Last Version) - Disassembly

- 23.3 Limited Slip Differential Unit 45% (Last Version) - Assembly

- Section 24 - Preloaded Limited Slip Differential Unit 45% Unit (Old Version)

- 24.1 Exploded View

- 24.2 Preloaded Limited Slip Differential Unit 45% Unit (Old Version) - Disassembly

- 24.3 Preloaded Limited Slip Differential Unit 45% Unit (Old Version) - Disassembly

- Section 25 - Preloaded Limited Slip Differential Unit 45%(Intermediate Version)

- 25.1 Exploded View

- 25.2 Preloaded Limited Slip Differential Unit45% (Intermediate Version) - Disassembly

- 25.3 Preloaded Limited Slip Differential Unit 45%(Intermediate Version) - Assembly

- Section 26 - Preloaded Limited Slip Differential Unit 45%(Last Version)

- 26.1 Exploded View

- 26.2 Preloaded Limited Slip Differential Unit 45%(Last Version) - Disassembly

- 26.3 Preloaded Limited Slip Differential Unit 45%(Last Version) - Assembly

- Section 27 - Bevel Pinion: Flanged to Reduction Gear 603

- 27.1 Exploded View

- 27.2 Bevel Pinion: Flanged to Reduction Gear 603 - Disassembly

- 27.3 Bevel Pinion: Flanged to Reduction Gear 603 - Assembly

- Section 28 - Ring and Pinion Adjusting: Version Pinion Cover and Single Arm

- 28.1 Exploded View

- 28.2 Ring and Pinion Adjusting: Version Pinion Cover and Single Arm - Install and Adjust

- Section 29 - Ring and Pinion Adjusting: Version Pinion Integral and Double Arm

- 29.1 Exploded View

- 29.2 Ring and Pinion Adjusting: Version Pinion Integral and Double Arm -install and Adjust

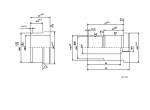

- Section 30 - Special Tools

- 30.1 T1

- 30.2 T2

- 30.3 T3

- 30.4 T4

- 30.5 T5

- 30.6 T6

- 30.7 T7

- 30.8 T8

- 30.9 T9

- 30.10 T10

- 30.11 T11

- 30.12 T12

- 30.13 T13

- 30.14 T14

- 30.15 T16

- 30.16 T17

- 30.17 T18

Screenshots for Caterpillar Telehandler TH255, TH255C Axle Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Caterpillar Telehandler TH255, TH255C Axle Service Manual PDF:

Caterpillar Lift Trucks 2025 (MCFS) Asia Parts Catalog and Service Manuals

The Caterpillar Lift Trucks 2025 (MCFS Parts & Service Information Database contains information on parts and accessories, instructions, and service manuals for Caterpillar lift trucks for the Asia market.

299$

[12/2024]

|

Caterpillar Lift Trucks 2025 (MCFA) USA Parts Catalog and Service Manuals

The Caterpillar Lift Trucks 2025 (MCFA) Parts & Service Information Database contains information on parts and accessories, instructions, and service manuals for Caterpillar lift trucks for the US market.

299$

[12/2024]

|

Caterpillar ET 2025C (CAT ET 2022A, 2021B, 2020A, 2019B) Electronic Technician Diagnostic Software

Caterpillar ET 2025C (replaces CAT ET 2022, 2023C) + WinFlash and 10-bit factory password generator is software Caterpillar dealers use.

250$

[11/2025]

|

Caterpillar Lift Trucks 2025 (MCFE) Europe Parts Catalog and Service Manuals

The Caterpillar Lift Trucks 2025 (MCFE) Parts & Service Information Database contains information on parts and accessories, instructions, and service manuals for Caterpillar lift trucks for the EU market.

299$

[12/2024]

|