![spare parts catalog CLAAS Parts Doc Offline Update v919 [02.2026]](/imgs/type_zapch.gif)

Case Magnum 255 Tractors PDF Operator’s manuals

[2007]These manuals contain important information for the safe operation, setup and maintenance of your Case tractor. The Operator's Manuals contain a wealth of information needed to use the Magnum 255 Series tractor safely and efficiently.

Use these manuals as a safety guide and the tractor will remain a reliable work tool if it is in good working order and properly maintained. These guides will help you do just that.

These manuals are divided into several groups, such as maintenance, special repair instructions, safety information, operating instructions, troubleshooting, as well as all additional information that is provided specifically for the CASE tractor (see Table of Contents below)

Make sure you understand the content of this manual and use it to the fullest extent possible. The manual is supplied in PDF format, and in order to display all diagrams and information correctly, we advise you to install Adobe PDF Reader. You can contact us if you have any questions or need our help.

Model:

Magnum 255

Contents:

- 1 – TO THE OWNER

- STATEMENT OF TRACTOR INTENDED USE

- OPERATOR’S MANUAL STORAGE COMPARTMENT

- TRANSPORT TOWED EQUIPMENT AT SAFE SPEEDS

- PRODUCT IDENTIFICATION AND SERIAL NUMBERS

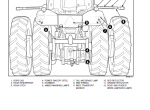

- MACHINE COMPONENTS

- BUSINESS BAND RADIOS

- FRAME REINFORCEMENT KITS

- 2 – SAFETY/DECALS

- SAFETY RULES

- PERSONAL SAFETY

- INSTRUCTIONAL SEAT SAFETY

- MAINTENANCE SAFETY

- FIRE SAFETY

- BATTERY SAFETY

- MACHINE OPERATION AND ROLL-OVER SAFETY

- HAZARDOUS CHEMICALS

- SAFETY DECALS

- ROLLOVER PROTECTIVE STRUCTURE (ROPS)

- CAB STRUCTURAL FRAME (CSF)

- CLEANING CAB WINDOWS

- INTERIOR REAR VIEW MIRROR

- SEAT BELTS

- TRACTOR WARNING LAMPS AND SLOW MOVING VEHICLE (SMV) SYMBOL

- IMPLEMENT WARNING LAMPS AND SMV SYMBOL

- SAFETY CHAIN

- 3 – OPERATING CONTROLS

- TRACTOR ACCESS

- OPERATOR SEAT AND CONTROLS

- INSTRUCTIONAL SEAT (IF EQUIPPED)

- STEERING COLUMN CONTROLS

- CENTER CONSOLE CONTROLS

- FOOT PEDALS

- RIGHT HAND CONSOLE CONTROLS

- ARMREST CONSOLE CONTROLS

- RIGHT HAND FENDER CONTROLS

- AUTOMATIC TEMPERATURE CONTROL SYSTEM (IF EQUIPPED)

- AFS 200 DISPLAY

- AFS PRO 600 DISPLAY

- REAR WINDOW

- DOME LAMP

- MAP LAMP (IF EQUIPPED)

- STORAGE COMPARTMENT

- RADIO (IF EQUIPPED)

- MP3 PLAYER JACK (EARLY VERSION) (IF EQUIPPED)

- MP3 PLAYER JACK (LATER VERSION) (IF EQUIPPED)

- SUN SHADE (IF EQUIPPED)

- INTERIOR REAR VIEW MIRROR

- EXTENDABLE MIRRORS (IF EQUIPPED)

- UTILITY CONSOLE

- REAR FENDER CONTROLS

- 4 – INSTRUMENTATION

- INSTRUMENTATION CLUSTER OVERVIEW

- PROGRAMMING THE INSTRUMENTATION DISPLAY

- PROGRAMMING THE OPERATOR ADJUST MENU

- WARNING/FAULT DISPLAYS

- INSTRUMENTATION CLUSTER OPERATION

- 5 – OPERATING INSTRUCTIONS

- BEFORE STARTING THE ENGINE

- SERVICE INDICATOR LAMPS AND DISPLAYS

- SEAT BELTS

- NORMAL ENGINE STARTING PROCEDURE

- STOPPING THE ENGINE

- COLD TEMPERATURE OPERATION

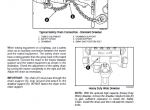

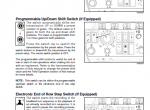

- POWER SHIFT TRANSMISSION

- TRANSMISSION

- SUSPENDED MFD AXLE OPERATION (IF EQUIPPED)

- CUSHION HITCH RIDE CONTROL OPERATION (IF EQUIPPED)

- CONSTANT ENGINE SPEED OPERATION

- TOWING THE TRACTOR

- HOW TO TRANSPORT THE TRACTOR

- 6 – FIELD OPERATION

- GENERAL PROCEDURES FOR CONNECTING IMPLEMENTS

- POWER TAKEOFF (PTO)

- THREE POINT HITCH

- HITCH OPERATION

- DRAWBAR PREPARATION

- REMOTE HYDRAULICS

- LOADER OPERATION

- CHEMICAL TANK MOUNTING

- AUXILIARY POWER CONNECTIONS

- MONITOR MOUNTING

- GROUND SPEED SENSOR CONNECTOR

- TRAILER BRAKE CONNECTOR (IF EQUIPPED)

- CAB STEPS

- 7 – IN-FIELD PERFORMANCE

- DIFFERENTIAL LOCK

- MFD OPERATION

- BALLASTING YOUR TRACTOR FOR OPTIMUM PERFORMANCE

- WHEEL SLIP

- POWER HOP

- MECHANICAL FRONT DRIVE (MFD) AXLES

- MFD STEERING AND OSCILLATION STOPS

- FRONT WHEEL FENDERS (IF EQUIPPED)

- REAR AXLE

- TRACTOR JACKING POINTS

- REAR WHEEL TREAD SETTING - SINGLES

- REAR WHEEL TREAD SETTING - DUALS

- REAR WHEEL TREAD SETTING - TRIPLES

- 8 – LUBRICATION/FILTERS/FLUIDS/MAINTENANCE

- ENVIRONMENT

- PLASTIC AND RESIN PARTS

- TOOL BOX (IF EQUIPPED)

- SYSTEM CAPACITIES

- OPENING THE HOOD

- LUBRICATION/MAINTENANCE CHART

- 9 – ELECTRICAL SYSTEM

- SPECIFICATIONS

- RADIO REGIONAL PROGRAMMING

- BATTERY SYSTEM SERVICING

- BULB AND LAMP REPLACEMENT

- 10 – SPECIFICATIONS

- DIESEL ENGINE

- POWER TRAIN

- TRAVEL SPEEDS

- MAXIMUM RECOMMENDED OPERATING WEIGHTS

- INDEX

Screenshots for Case Magnum 255 Tractors PDF Operator’s manuals:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Case Magnum 255 Tractors PDF Operator’s manuals:

eTimGo AGCE for CNH EST 2025 all brands OFFLINE

eTimGo AGCE for CNH EST 05/2025 all brands OFFLINE. Manuals, electrical bulletin diagrams, and diagnostic procedures are provided, including some spare parts catalogs.

1200$

[05/2025]

|

New Holland Electronic Service Tool CNH EST 9.14 [2026] Engineering Diagnostic Software![Diagnostic Software New Holland Electronic Service Tool CNH EST 9.14 [2026] Engineering Diagnostic Software](https://www.epcatalogs.com/file/base/7wA2eiQzaw96Mud+nQLe62FMZmZxTTk819fwjKwFzn9gZlueS7pErMi5cA5I4B9rnJjvyM2KHVeYq8dAqLFqg6eVylUigwGA14M6GWQO8C:2FaqSq5rLX38HGZjM8wALuylflj8yTHY6HQGzotXlCesqQ=/case-new-holland-electronic-service-tools-cnh-est-software-download.png)

The dealer software Electronic Service Tools CNH EST 9.14 update 1 (ex v9.3, v9.4, v9.5, 9.6, 9.7) with the highest engineering access Level available for download or shipping worldwide with online support!

250$

[03/2026]

|

Original CNH DPA5 Diagnostic Service Tool Adapter Cable Kit + CNH EST 9.12

The Case, New Holland (CNH) DPA5 adapter kit includes all the cables. This is a genuine CNH DPA5 kit. Include CNH 9.12 Engineering Software 2025

1699$

[2025]

|

CNH Display Codes for the Paid Features 2023 v1.1

The app generates codes for CNH displays to unlock paid features. Codes are entered through the display

3999$

[2024]

|