![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

New Holland L175 C175 Skid Steer and Track Loaders Repair Manual PDF

[05/2007]Repair manual contains complete technical information and instructions for the proper execution of the current and capital repairs, maintenance for L175 skid steer and C175 track loaders New Holland.

This repair manual is an assistant to users for self-service, overhaul and repair, all maintenance procedures, diagnostic tests that can help you quickly find the faults and repair them.

Also repair manual provides detailed and clear images which contains much more information about the repair and maintenance.

This manual is presented in the format of PDF.

Repair manual has a nice and friendly interface, the software works after installing Adobe Reader, which allows you to find the necessary information to the user, as well as to print out individual pages or the entire text as a whole.

Section Index:

- Section 00 - GENERAL INFORMATION

- Introduction

- About Improvements

- Company Policy

- Parts and Accessories

- Model Codes

- Precautionary Statements

- Safety Precaution Information

- General Safety Information

- Machine Model and Serial Number Location

- Engine Model and Serial Number Location

- Hardware Torque Specifications

- Installation of Adjustable Fittings in Straight Thread O Ring Bosses

- Standard Torgue Data for Hydraulic Tubes and Fittings

- Pipe Thread Fitting Torgue

- Lubricants and Coolants

- Sealants

- Properly Support a Raised Machine

- Properly Support Boom on Boom Lock Pins

- Raising Boom Without Hydraulic Oil Flow

- Raising Boom Without Battery Voltage (12V)

- Reattaching Cylinders After Repair with Boom Resting on Boom Lock Pins

- Major Unit Overhaul

- Cab and Boom Tilt Procedure

- Craning the Skid Steer

- Special Tools

- specifications

- Cab and Boom Tilt Procedure (Cab Upgrade Machines Only)

- Section 10 - ENGINE - L175 - N844LT, C175 - N844LT

- General Engine Information

- General Description

- Engine Component Descriptions

- Engine Model and Serial Number Location

- Turbocharger Lubrication

- Safety Precautions

- General Engine Specifications

- Troubleshooting

- L175 - Excessive Oil Consumption

- Specifications - Service Standards

- Torque Specifications

- Engine Components Electrical Diagram

- Engine Removal

- Engine Disassembly Sequence

- Engine Component Maintenance

- Valve Seat

- Cylinder Block

- Piston and Piston Rings

- Connecting Rod

- Bearing Holder

- Front Crankshaft Bearing (Bushing)

- Crankshaft

- Flywheel and Ring Gear

- Camshaft Assembly

- Camshaft Gear and Bearing Assembly

- Timing Gear

- Oil Pump

- Oil Filter

- Water Pump Assembly and Thermostat Housing

- Thermostat

- Governor

- Governor Operation

- Engine Reassembly Sequence

- Crankshaft and Bearing Holder Assembly

- Rear Oil Seal

- Backplate/Flywheel Housing

- Flywheel

- Piston and Connecting Rod

- Oil Intake and Oil Strainer

- Oil Sump

- Dipstick and Tube

- Front Plate

- Idler Gear and Oil Pump Assembly

- Timing Gear Case Installation

- Crankshaft Pulley

- Injection Pump Installation

- Adjusting the Fuel Injection Timing

- Spill Timing Procedure

- Reinstallation of Engine into Skid Steer Frame

- How to Operate the Engine After Overhaul

- Cooling System

- Cooling System Operation

- Water Pump Assembly and Thermostat Housing

- Radiator

- Fuel System

- Fuel Specifications

- Diesel Fuel

- Diesel Fuel Storage

- Fuel System Components

- Fuel Guage

- Cold Start Aid

- Fuel Filter System

- Priming the Fuel System

- Fuel System Testing

- Fuel System Components

- Fuel Injection Timing

- Turbocharger - L175 N844LT Engine

- Turbocharger Removal

- Miscellaneous Engine Electrical

- Shut-off Solenoid

- Special Tools

- Labor Guide

- Section 27 - TRACKS AND MOTORS

- Specifications

- Special Torques

- Wheel Hub Housing - Remove

- Wheel Hub Housing - Install

- Drive Sprocket - Remove

- Drive Sprocket - Install

- Rubber Track - Remove

- Rubber Track - Install

- Rubber Track - Tension Adjust

- Track Tension Mechanism - Remove

- Track Tension Mechanism - Install

- Track Roller - Remove

- Track Roller - Install

- Idler Wheel - Remove

- Idler Wheel - Install

- Track Drive Motor - Remove

- Track Drive Motor - Install

- Track Drive Motor - Disassembly

- Track Drive Motor - Assembly

- Section 29 - HYDROSTATIC TRANSMISSION

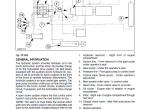

- General Information

- Operation

- Specifications

- Troubleshooting

- Hydrostatic Drive System Testing

- Hydrostatic System Oil Flow

- Hydrostatic Charge System Pressure Test

- Hydrostatic Pump Case Drain Test

- Hydrostatic Pump High Pressure Test

- Hydrostatic Pump Efficiency Test

- Hydrostatic Motor Case Drain Test

- Hydrostatic Motor Efficiency Test

- Hydraulic, Hydrostatic System Air Ingress Test

- Hydrostatic Pumps

- Hydrostatic Pump Removal

- Hydrostatic Pump Disassembly

- Hydrostatic Pump Parts Inspection

- Hydrostatic Pump Reassembly

- Hydraulic System Pump Installation (Without High Flow)

- Hydraulic System Pump/High Flow Pump Installation

- Hydrostatic Pump Reinstallation

- Hydrostatic Motor

- Hydrostatic Motor Removal

- Hydrostatic Motor Disassembly

- Hydrostatic Motor Parts Inspection

- Hydrostatic Motor Reassembly

- Hydrostatic Motor Reinstallation

- Hydraulic System Cleaning Procedure

- Start-up Procedure After Rebuild (After Pump or Motor Replacement)

- Charge Check Valve

- Charge Check Valve Removal and Replacement

- Section 33 - BRAKES AND CONTROLS

- PARKING BRAKE

- Parking Brake Removal

- Parking Brake Reinstallation

- Parking Brake Disassembly

- Parking Brake Reassembly

- Troubleshooting - Parking Brake Button - Testing

- Troubleshooting - Electrical Solenoid - Testing

- Brake Valve - Illustration

- Brake / Two-Speed Valve - Illustration

- Section 35 - HYDRAULIC SYSTEM

- General Information

- Hydraulic System Compatibility

- Boom Cylinder Pivot Pins

- Boom Cylinder Pivot Pin Location and Machine Usage

- Control Valve Power Beyond

- Specificatios

- Troubleshooting

- Auxiliary Boom Hydraulics Troubleshooting

- Hydraulic System Testing

- Hydraulic System Oil Flow

- Control Valve - Bucket Spool Shifted

- Control Valve - Boom Spool Shifted

- Control Valve - Auxiliary Spool. Shifted

- Main System Pressure Tests

- Checking Main System Pressure at Boom Cylinders

- Checking Main System Pressure at Bucket Cylinders

- Checking Main System Pressure at Auxiliary Boom Hydraulic Quick Couplers

- Boom Circuit Relief Valve Test

- Gear Pump Flow Efficiency Test

- Boom and Bucket Spool Lock Solenoid Test

- Hydraulic, Hydrostatic System Air Ingress Test Control Valve Specifications

- Control Valve Removal

- Control Valve Disassembly and Inspection

- Control Valve Parts Inspection

- Control Valve Reassembly

- Control Valve Reinstallation

- Hydraulic Pump Specifications

- Hydraulic Pump Removal

- Hydraulic Pump Removal/Disassembly (Without High Flow)

- High Flow Pump Parts Inspection

- Hydraulic Pump Parts Inspection

- Hydraulic Pump Reassembly/Installation (Without High Flow)

- Hydraulic Pump and High Flow Pump Reassembly/Installation

- New Hydraulic Pump Installation (Without High Flow)

- New Hydraulic Pump/High Flow Pump Installation

- Gear Pump Start-up Procedure

- Cylinders, Boom and Bucket

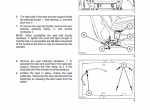

- Boom Cylinder Removal

- Boom Cylinder Disassembly

- Boom Cylinder Parts Inspection

- Boom Cylinder Reassembly

- Boom Cylinder Reinstallation

- Bucket Cylinder Removal

- Bucket Cylinder Disassembly

- Bucket Cylinder Parts Inspection

- Bucket Cylinder Reassembly

- Bucket Cylinder Reinstallation

- Pedal Controls

- Pedal Removal (With Boom and Bucket Pedal Controls)

- Pedal Inspection (With Boom and Bucket Pedal Controls

- Pedal Reinstallation (With Boom and Bucket Pedal Controls

- Pedal Removal (With Boom and Bucket Hand Controls

- Pedal Inspection (With Boom and Bucket Hand Controls

- Pedal Reinstallation (With Boom and Bucket Hand Controls

- Hydraulic Cooling, Filter, Reservoir System

- Filter System

- Filter Removal

- Base Remova

- Reassembly

- Oil Cooler

- Oil Cooler Removal

- Oil Cooler Reassembly

- Oil Reservoir

- Oil Reservoir Removal

- Oil Reservoir Reinstallation

- Adapting Attachments

- Labor Guide

- Machines Equipped With Pilot Controls

- Specifications

- Loader Function Troubleshooting

- Pilot Pressure Test

- Illustration - Loader Control

- Right Control Handle - Removal

- Right Control Handle - Installation

- Hydraulic Schematic - Frame 1- (Mechanical Control Machines)

- Hydraulic Schematic - Frame 2- (Mechanical Control Machines)

- Hydraulic Schematic - Frame 3-(Mechanical Control Machines)

- Hydraulic Schematic - Frame 4- (Mechanical Control Machines)

- Hydraulic Schematic - Frame 5- (Mechanical Control Machines)

- Hydraulic Schematic - Frame 6- (Mechanical Control Machines)

- Hydraulic Schematic - Frame 7- (Mechanical Control Machines)

- Hydraulic Schematic - Frame 8- (Pilot Control Machines)

- Hydraulic Schematic - Frame 9- (Pilot Control Machines)

- Hydraulic Schematic - Frame 10- (Pilot Control Machines)

- Hydraulic Schematic - Frame 11- (Pilot Control Machines)

- Hydraulic Schematic - Frame 12- (Pilot Control Machines)

- Hydraulic Schematic - Frame 13- (Pilot Control Machines)

- Hydraulic Schematic - Frame 14- (Pilot Control Machines)

- Hydraulic Schematic - Frame 15- (Pilot Control Machines)

- Hydraulic Schematic - Frame 16- (Pilot Control Machines)

- Section 37 - TOWING HOOKS AND BALLASTING

- Rear Counterweights

- Rear Counterweight Support Removal

- Section 39 - FRAMES

- General Information

- ROPS

- ROPS Frame

- ROPS Remival

- ROPS Reinstallation

- Labor Guide

- ROPS Removal (Cab Upgrade Machines Only)

- ROPS Reinstallation (Cab Upgrade Machines Only)

- Section 44 - AXLES AND WHEELS

- General Information

- Specifications

- Troubleshooting

- Testing

- Axles

- Axle Housing Assembly Removal

- Axle Disassemby

- Axle Parts Inspection

- Axle Reassembly

- Axle Housing Reinstallation

- Final Drive

- Drive Chain and Sprocket Removal

- Final Drive Parts Inspection

- Final Drive Reassemby

- Drive Chain - Tension Adjust

- Tire/Wheels

- Labor Guide

- Section 50 - CAB CLIMATE CONTROL

- Heater/Defroster (Cab)

- Labor Guide

- Air Conditioning Sytem Special Tools

- Air Conditioning Sytem General Specifications

- Air Conditioning Sytem Discharging and Evacuate and Recovery

- Air Conditioning Sytem Charging

- Compressor Removal

- Compressor Installation

- Compressor Oil Level Check

- Compressor Belt Measure and Tension Adjust

- Compressor Magnetic Clutch Disassemble

- Compressor Magnetic Clutch Assembly

- Air Conditioning Sytem Removal

- Air Conditioning Sytem Installation

- Air Conditioning Sytem Condenser Removal

- Air Conditioning Sytem Condenser Installation

- Air Conditioning Sytem Evaporator Removal

- Air Conditioning Sytem Evaporator Installation

- Receiver/Drier Removal and Installation

- Air Conditioning Sytem Visual Inspection and Troubleshooting

- Air Conditioning Sytem Testing

- Air Conditioning Sytem Leakage Test

- Air Conditioning Sytem Problem Solving

- Air Conditioning Sytem Problem Solving

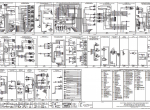

- Section 55 - ELECTRICAL SYSTEM

- General Electrical Information

- Definition of Terms

- Adapting Attachments Requiring 12V Electrical Power

- Specifications

- Wire Identification and Circuit Diagram Legend

- Electrical Diagram - Starting System

- Electrical Diagram - Power Distribution

- Electrical Diagram -Safety Interlock and Fuel Supply System

- Electrical Diagram - Instrument Cluster Monitoring System

- Electrical Diagram - Standard Lamps

- Electrical Diagram - Loader Arm Auxiliary Electrical Control Box (Optional)

- Electrical Diagram - Loader Arm Auxiliary Electric Power Controls (Optional)

- Electrical Diagram - Flasher and Turn Signals North America Electrical

- Electrical Diagram - Main Electrical European On-Road Regulations

- Electrical Diagram - Boom/Rear Electrical European On-Road Regulations

- Electrical Diagram - Right-Hand Handle (Option) Electrical Multifunction Adaptation

- Electrical Diagram - Left-Hand Handle (Options)

- Electrical Diagram - Right-Hand Handle (Options)

- Electrical Diagram - Glow Plugs

- Electrical Diagram - Rotating Beacon (Optional)

- Electrical Diagram - Two Speed (Optional)

- Electrical Diagram - Horn (Optional)

- Electrical Diagram - Accessory Outlet (Optional)

- Electrical Diagram - Back-up Alarm (Optional)

- Electrical Diagram - Wiper/Washer (Optional)

- Electrical Diagram - Auxiliary Hydraulics (Optional)

- Electrical Diagram - High Flow (Optional)

- Electrical Diagram - Hydraulic Coupler (Optional)

- Electrical Diagram - Heating and Air Conditioning (Optional)

- Electrical Diagram - Pilot Hydraulic Controls

- Electrical Diagram - Ground Connections

- Electrical Diagram - Ground Connections

- Wire Identification and Circuit Diagram Legend (Cab Upgrade Machines)

- Electrical Diagram - Starting System (Cab Upgrade Machines)

- Electrical Diagram - Power Distribution (Cab Upgrade Machines)

- Electrical Diagram -Safety Interlock and Fuel Supply System (Cab Upgrade Machines)

- Electrical Diagram - Instrument Cluster Monitoring System (Cab Upgrade Machines)

- Electrical Diagram - Standard Lamps (Cab Upgrade Machines)

- Electrical Diagram - Loader Arm Auxiliary Electrical Control Box (Optional)

- (Cab Upgrade Machines)

- Electrical Diagram - Loader Arm Auxiliary Electric Power Controls (Optional)

- (Cab Upgrade Machines)

- Electrical Diagram - Flasher and Turn Signals North America Electrical

- (Cab Upgrade Machines)

- Electrical Diagram - Main Electrical European On-Road Regulations

- (Cab Upgrade Machines)

- Electrical Diagram - Boom/Rear Electrical European On-Road Regulations

- (Cab Upgrade Machines)

- Electrical Diagram - Work Lamps (Cab Upgrade Machines)

- Electrical Diagram - Control Lever Interface (Cab Upgrade Machines)

- Electrical Diagram - Left-Hand Handle (Options) (Cab Upgrade Machines)

- Electrical Diagram - Right-Hand Handle (Options) (Cab Upgrade Machines)

- Electrical Diagram - Grid Heater System (Cab Upgrade Machines)

- Electrical Diagram - Rotating Beacon (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Two Speed (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Horn (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Accessory Outlet (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Back-up Alarm (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Wiper/Washer/Door Switch (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Auxiliary Hydraulics (Optional) (Cab Upgrade Machines)

- Electrical Diagram - High Flow (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Hydraulic Mount Plate (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Heating and Air Conditioning (Optional) (Cab Upgrade Machines)

- Electrical Diagram - Pilot Hydraulic Controls

- Electrical Diagram - Ground Connections (Cab Upgrade Machines)

- Electronic Instrument Cluster (EIC) Panel

- Electronic Instrument Cluster (EIC) Panel (Cab Upgrade Machines)

- Electronic Instrument Cluster Operating Instructions

- Electronic Instrument Cluster Troubleshooting

- Advanced Instrument Cluster (AIC) Panel (Optional)

- Advanced Instrument Cluster (AIC) Panel (Optional) (Cab Upgrade Machines)

- Advanced Instrument Cluster Operating Instructions

- Advanced Instrument Cluster Troubleshooting

- Removal, Installation and Wiring of Electrical Components

- Battery Removal and Installation

- Cab Fuse Block and Panel Removal and Installation

- Seat Switch Removal

- Seat Switch Installation

- Seat Belt Buckle and Switch Assembly Removal and Installation

- Road Light and Work Light Switch Removal and Installation

- Engine Fuse and Relay Panel

- Start Interlock Relay Removal and Installation

- Engine Fuse Block Removal and Installation

- Preheat Relay Removal and Installation

- Preheat Glow Plug Removal and Installation

- Fuel System Components

- Electric Fuel Pump

- Electric Fuel Pump Removal

- Fuel Shutoff Solenoid

- Fuel Shutoff Solenoid Testing

- Replacement of Fuel Shutoff Solenoid

- Air Filter Restriction Indicator Switch Removal and Installation

- Engine Coolant Temperature Sender Removal and Installation

- Engine Oil Pressure Switch Removal and Installation

- Hydrostatic Charge Pressure Switch Removal and Installation

- Hydraulic Oil Filter Restriction Switch Removal and Installation

- Hydraulic Oil Temperature Sender Removal

- Hydraulic Oil Temperature Sender Installation

- Boom/Bucket Control Valve Spool Lock Solenoid Removal and Installation

- Road/Work Lights

- Alternator (55 Amp Version)

- Alternator Service Specifications

- Alternator - System Testing and Troubleshooting

- Initial Tests

- Alternator Removal

- Alternator Disassembly

- Alternator Installation

- Starter

- Starter Motor Troubleshooting

- Starter Motor Removal

- Starter Motor Disassembly

- Starter Motor Inspection and Repair

- Starter Motor Reassembly

- Starter Motor Installation

- Miscellaneous Engine Components

- Glow Plugs and Glow Plug Troubleshooting

- Oil Pressure Switch

- Fuel Shutoff Solenoid

- Labor Guide

- Section 82 - FRONT LOADER (BOOM AND MOUNTING PLATE)

- General Information

- Buckets

- Boom Lock Pins and Linkage

- Boom

- Attachment Mounting Plate

- Boom and Cylinder Pivot Pins

- Boom and Cylinder Pivot Pin Location and Machine Usage

- Boom and Cylinder Pivot Pins Size

- Pallet Fork

- Utility Fork

- Bucket Cutting Edge (Replacement)

- Bucket Latch Plate Installation Procedure

- Dirt Tooth Kit Installation

- Bucket Tooth Spacing

- Boom Lock Pin/Linkage

- Boom Lock Pin/Linkage Removal

- Boom Lock Pin/Linkage Reinstallation

- Boom, Upper and Lower Link

- Boom, Upper and Lower Link Removal

- Front Boom Mounting Plate Pivot Hub Replacement

- Boom, Upper and Lower Link Reinstallation

- Attachment Mounting Plate

- Attachment Mounting Plate Removal

- Repair/Rebuild Mounting Plate

- Latch Lever and Pin Removal/Repair

- Attachment Mounting Plate Parts Inspection

- Checking Procedure for Buckets and Attachments

- Checking Procedure

- Checking the Loader Faceplate

- Labor Guide

- Section 88 - ACCESSORIES

- General Information

- Adapting Attachments Requiring 12V Electrical Power

- Hydraulic System Compatibility

- Arm Pads For Cab Side Panels

- Armrests for Deluxe Seat

- Forearm Rests

- Back-up Alarm

- Block Heater (Engine)

- Electric Power Supply (12 Volt, 15 Amp)

- Exhaust (Engine)

- Aspirator Precleaner Muffler

- High Flow Hydraulics

- High Flow Hydraulics Troubleshooting

- High Flow Hydraulics Component Replacement

- Horn

- Shoulder Belt (Seat)

- Slow-moving Vehicle (SMV) Sign Kit

- Warning Light (Rotary Beacon)

- Warning Lights (Four-way Flashers/Turn Signal/Horn)

- Labor Guide

- Section 90 - PLATFORMS, CAB, BODYWORK, AND DECALS

- General Information

- Seat and Seat Pan Support

- Cab Inner Shell

- Seat Removal

- Seat Pan Support Removal

- Seat, Switch and Pan Reinstallation

- Cab Inner Shell

- Cab Inner Shell Removal

- Cab Inner Shell Reinstallation

- Safety Decals

- Labor Guide

- ELECTRICAL SCHEMATICS

- HYDRAULIC SCHEMATICS

Screenshots for New Holland L175 C175 Skid Steer and Track Loaders Repair Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for New Holland L175 C175 Skid Steer and Track Loaders Repair Manual PDF:

eTimGo AGCE for CNH EST 2025 all brands OFFLINE

eTimGo AGCE for CNH EST 05/2025 all brands OFFLINE. Manuals, electrical bulletin diagrams, and diagnostic procedures are provided, including some spare parts catalogs.

1200$

[05/2025]

|

New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software![Diagnostic Software New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software](https://www.epcatalogs.com/file/base/7wA2eiQzaw96Mud+nQLe62FMZmZxTTk819fwjKwFzn9gZlueS7pErMi5cA5I4B9rnJjvyM2KHVeYq8dAqLFqg6eVylUigwGA14M6GWQO8C:2FaqSq5rLX38HGZjM8wALuylflj8yTHY6HQGzotXlCesqQ=/case-new-holland-electronic-service-tools-cnh-est-software-download.png)

The dealer software Electronic Service Tools CNH EST 9.13 update 3 (ex v9.3, v9.4, v9.5, 9.6, 9.7) with the highest engineering access Level available for download or shipping worldwide with online support!

250$

[01/2026]

|

Original CNH DPA5 Diagnostic Service Tool Adapter Cable Kit + CNH EST 9.12

The Case, New Holland (CNH) DPA5 adapter kit includes all the cables. This is a genuine CNH DPA5 kit. Include CNH 9.12 Engineering Software 2025

1699$

[2025]

|

CNH Display Codes for the Paid Features 2023 v1.1

The app generates codes for CNH displays to unlock paid features. Codes are entered through the display

3999$

[2024]

|