![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Massey Ferguson MF 5300 Series Tractors Service Manual PDF

[2013]Presented at the site new information for Massey Ferguson MF 5300 series tractors these are manuals of repair and service, special instructions for maintenance, technical specifications, wiring diagrams, step by step instructions for operation and maintenance, machine data, the diagnostic program, technical service instructions for agricultural equipment.

Also in these service manuals, you find troubleshooting information, assembly, and disassembly, inspection, and control, safety precautions, technical specification, pictures with step by step descriptions and etc.

The set of service manuals is your irreplaceable assistant which helps use, maintenance, and repair Massey Ferguson MF 5300 series tractors. This set includes PDF manuals that work with Adobe PDF Reader. If necessary, you can print the entire document or selected partitions. Make sure you understand the contents of this manual and use it to full effect at every opportunity.

The following manual is a part of the massive Massey Ferguson dealer database for Service and Spare parts research.

Applied models:

MF 5335

MF 5340

MF 5355

MF 5360

MF 5365

Structure of the Manual:

- A - Introduction

- 1 - Presentation

- 2 - Safety

- 3 - Correct workshop techniques

- 4 - Basics of measurement

- 5 - General table of recommended torques for bolts

- 6 - Technical units

- 7 - Loctite products for the workshop

- 8 - AGCO environmental policy

- 9 - Compulsory recycling of batteries

- B - Splitting the tractor

- 1- Introduction

- 2 - Splitting the tractor between the engine and front axle

- 3 - Splitting the tractor between the engine and gearbox

- 4 - Splitting the tractor between the gearbox and rear axle

- 5 - Splitting the tractor between the gearbox and rear axle

- 6 - Front hood sheet metal removal

- C - 2WD front axle

- 1 - Introduction

- 2 - Front wheel alignment

- 3 - Wheel Hubs

- 4 - Sleeve and master pin

- 5 - Front axle central beam

- 6 - Pivot and steering cylinder

- D - Carraro 4WD front axle: Ca 20.19 and 20.21

- 1 - Introduction

- 2 - 4WD front axle engagement

- 3 - Final drive

- 4 - Final drive pivoting

- 5 - Half-shaft spiders

- 6 - Bushings and retainers of trumpets and pivots

- 7 - Pinion and differential assy

- 8 - Steering cylinder

- 9 - Bearing lift axis

- 10 - General tightening torques

- E - Perkins engines

- 1 - Adjustment of valve tip clearance

- 2 - Nozzles' inspection

- 3 - Adjustment of the injection point

- 4 - Compression test for cylinders

- 5 - Basic technical specifications

- 6 - Workshop specifications - P4001 / 4001T engines

- 7 - Workshop specifications - 1000 Series

- F - Clutches

- 1 - Clutches and flywheels fitted on the MF 5300 Series tractors

- 2 - General information and recommendations about clutches

- 3 - Split-torque clutch

- 4 - Engine flywheel

- 5 - Clutch refitting and final adjustments

- 6 - Clutch troubleshooting

- 7 - Clutch engagement mechanism

- G1 - Eaton Synchromesh 12*4 gearbox

- 1 - Introduction

- 2 - Gearbox removal and adaptation to service support

- 3 - Gear selector system

- 4 - Slow and Fast range assy

- 5 - Front flange (input housing) and input shafts

- 6 - Main shaft (or output shaft)

- 7 - PTO output shaft and layshaft (lower shaft

- 8 - Reverse gear assy

- 9 - Synchronizer assemblies

- 10 - Component inspection and failure diagnosis (troubleshooting)

- G2 - 18*6 speed gearbox - SpeedShift

- 1 - Presentation

- Part 1: Gearbox (selection of High/Low range and 1st, 2nd, 3rd and Reverse)

- 2 - Gearbox

- 3 - Main gear shift lever

- 4 - Gearbox cover and selector rails

- 5 - Main shaft and clutch bearing

- 6 - Main shafts and front flange (input housing)

- 7 - SpeedShift clutch

- 8 - FRONT PTO shaft bearing

- 9 - PTO output shaft, layshaft, and main shaft

- 10 - Presentation

- 11 - Gear change selector

- 12 - General maintenance

- 13 - Adjusting output (upper) shaft pre-load

- 14 - Warning system encoder L - M - H ranges

- G3 - 8*8 speed gearbox

- 1 - Presentation

- 2 - Gearbox - removal, and refitting

- 3 - Control tie-rods and levers

- 4 - Main gear shift lever

- 5 - Gearbox top cover

- 6 - Selector mechanism

- 7 - Selector forks and guides

- 8 - Epicyclic unit

- 9 - PTO drive shaft front bearing

- 10 - Front flange and input shafts

- 11 - PTO output shaft, main shaft, lower shaft and gears

- G4 - 12*12 speed gearbox

- 1 - Introduction

- 2 - Gearbox - removal and refitting

- 3 - Control tie-rods and levers

- 4 - Main gear shift lever

- 5 - Gearbox top cover

- 6 - Selector mechanism, shafts, forks and rails

- 7 - PTO drive shaft front bearing

- 8 - Front flange and input shafts

- 9 - PTO output shaft, main shaft, layshaft and gears

- 10 - Speed range selector box - L - M - H

- G5 - 12*12 speed gearbox with creeper

- 1 - Presentation

- 2 - Creeper controls

- 3 - Creeper gear train assembly

- H - Rear axle

- 1 - Description and operation

- 2 - Final drive

- 3 - Trumpets

- 4 - Brakes

- 5 - Differential

- 6 - Pinion

- 7 - Adjustments and reinstallation of the crown gear and pinion

- 8 - Technical specifications

- I 1 - Ferguson hydraulic lift system

- 1 - Presentation

- 2 - Ferguson hydraulic linkage system operation

- 3 - Combined flow selector valve

- 4 - Ferguson hydraulic linkage pump

- 5 - Control spring (or master-spring)

- 6 - Hydraulic lift cover

- 7 - Internal lift ram cylinder

- 8 - Control lower levers, shafts and supports

- 9 - Cross-shaft and upper links

- 10 - Lift system external adjustments

- I 2 - Boschtronic hydraulic lift system

- Part 1: information in common between the system equipped with levers and the one with control panel

- 1 - General specifications

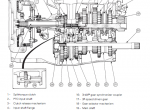

- 2 - Hydraulic diagram

- 3 - Hydraulic circuit

- 4 - Maintaining the system in good condition

- 5 - Lift control electro-valve

- 6 - Hydraulic adjustments

- 7 - Hydraulic lift cover, cross-shaft, and upper links

- 8 - Inner hydraulic cylinder

- 9 - Combined flow selector valve

- Part 2: Electronic system operated by levers

- 10 - Presentation

- 11 - Identification of controls fitted in the system with levers

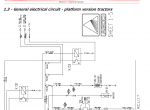

- 12 - Electrical diagram

- 13 - Troubleshooting (system with levers

- 14 - Electrical tests and adjustments

- Part 3: Electronic system operated by the control panel

- 15 - Presentation

- 16 - Identification of controls

- 17 - Electrical diagram

- 18 - Troubleshooting

- 19 - Control panel

- 20 - Tests and adjustments: are identical to the ones described in Chapter 14, concerning the system with levers.

- J - Power take-off: live and independent

- 1 - Presentation

- 2 - IPTO assy removal and refitting

- 3 - IPTO side cover and control valve assy

- 4 - Clutch disc pack assembly

- 5 - IPTO dual rotation - 1000 / 540 rpm

- 6 - IPTO output shaft, bearing shell and retainer

- 7 - IPTO controls

- L - Electrical system

- 1 - Presentation

- 2 - Electrical board: fuses, relays, and diodes

- 3 - Prestolite alternator

- 4 - Prestolite starter motor

- 5 - Instrument panel

- 6 - Miscellaneous components

- M - Auxiliary hydraulic system

- 1 - Introduction

- 2 - Technical specifications

- 3 - Auxiliary circuit general diagram

- 4 - General hydraulic circuits

- 5 - Description and overhaul of components

- 6 - Hydrostatic unit (Danfoss

- 7 - Hydraulic testing

- 8 - Hydraulic pump(s)

- N - Cab, ar conditioning system and heating

- 1 - Introduction

- 2 - Operation

- 3 - Technical features

- 4 - Safety Recommendations

- 5 - General maintenance

- 6 - Preventive maintenance control

- 7 - Electrical diagram

- 8 - Coolant refilling

- 9 - Troubleshooting

- 10 - Windshield wiper (front)

- 11 - Fan and heating system

- O - Tractor's general specifications

- Engine

- Electrical system - power and capacities

- Clutch

- Gearbox

- Theoretical maximum speed on road, in km / h (engine @ 2200 rpm)

- Rear Axle

- Front axle

- Brakes

- Hydraulic lift system

- Auxiliary hydraulic systems

- Independent Power-Take-Off

- Tractor weights - in kg

- Tractors general dimensions - in mm

- Filling Capacities - in liters

- Wheels nuts torques - kgf.m

- Drawbar

- Cab and air conditioning system (Optional)

- General electric diagram

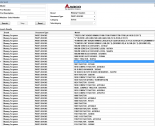

Screenshots for Massey Ferguson MF 5300 Series Tractors Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Massey Ferguson MF 5300 Series Tractors Service Manual PDF:

Full Agriculture Parts Literature Set 2021

Full Agriculture Parts and Service Literature Set 2022 is an electronic database catalog of spare parts of agricultural machinery, which combines outstanding performance and high reliability, such brands as Case, Deutz-Fahr, Fendt, John Deere, Massey Ferguson, New Holland, Same, Valtra.

1299$

[2015-2021]

|

Massey Ferguson AG USA 09/2020 Parts Catalog & Workshop Service Manuals

The 01/2020 version of the MF OEM software for Repair Manuals and Spare Parts research. Works with Windows 10, download or delivery on USB HDD.

150$

[09/2020]

|

Massey Ferguson Epsilon Europe 09/2020 Parts Books and Workshop Manuals

Massey Ferguson Epsilon is an electronic catalog of spare parts for all agricultural and other types of equipment Massey Ferguson, for the processing of materials. All the technical information contained in the catalog is designed for agricultural equipment Massey Ferguson, namely: food tractors, Italian tractors, tractor parts of Massey Ferguson.

150$

[09/2020]

|

Massey Ferguson Tractors 600

The program Massey Ferguson Tractors 600 series is an electronic directory that contains a repair manuals and maintenance manuals of tractors of models 600 Massey Ferguson, that contains describes the technical characteristics accessories, step by step instruction, service manuals, technical specifications, fitting instructions, repair manuals and diagnostics programs for tractor series 600 of company Massey Ferguson.

150$

[06/2009]

|