![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

New Holland E16 - E18 Excavators Workshop Manual PDF

[01/2005]Workshop manual is intended for serve and repair New Holland E16 - E18 Excavators.

This workshop manual has been prepared in order to increase repair quality, providing to the technicians the elements for a good knowledge of the product and showing the proper procedures to carry out the maintenance operations. We recommend to thoroughly read the content and follow it when necessary.

It is a concise guide. It covers construction features, operation principle, troubleshooting, disassembly and assembly of components and repair action.

Using this manual in the systematic and rational way it is possible to reduce the repairing errors and delay that could cause machine stop with a detriment of cost management.

Workshop manual comes in PDF format, includes 636 pages. All pages are printable. For work with the manual, you should use Adobe PDF Reader, to be sure all images/graphics will display correctly.

SECTION INDEX:

- SECTION 1 - HOW TO USE

- Sections index

- Introduction

- Features of the manual

- SECTION 2 - SAFETY RULES

- Safety rules

- Safety signs

- SECTION 3 - PRELIMINARY

- General precautions for repairs

- Escaping procedure in case of emergency

- International unit conversion system

- SECTION 4 - SPECIFICATION

- Foreword

- Identification data

- Noise levels (2000/14/EC)

- Summary plate for maintenance operations

- Basic components of the mini excavator

- Technical specifications

- Digging performances (canopy)

- Digging performances (cab)

- Transport dimensions (canopy)

- Transport dimensions (cab)

- Lifting capacities (cab)

- Lifting capacities (canopy)

- Machine and components weight (dry)

- Buckets application

- Filling chart

- SECTION 5 - TOOLS

- Tools of cylinders

- Tool of hydraulic pump

- Tool of pilot valve track

- Tool of roller track

- Tool of idler adjuster

- Tools of engine

- Tools of travel motor

- SECTION 6 - STANDARD MAINTENANCE TIMETABLE

- Preface

- Standard working timetable for the maintenance

- SECTION 7 - MAINTENANCE STANDARDS AND TEST PROCEDURES

- How to use maintenance standards and precautions

- Performance inspection standard table

- Measuring engine speed

- Measuring hydraulic oil pressure

- Measuring travel performances

- Measuring slew performances

- Measuring attachment operating performances

- Measuring slew bearing performances

- Measuring crawler tension

- SECTION 8 - HYDRAULIC SYSTEM

- Function and features of hydraulic circuit

- Hydraulic circuits and components

- Hydraulic circuit operation

- SECTION 9 - ELECTRICAL SYSTEM

- How to read circuit diagram

- SECTION 10 - ATTACHMENT

- Attachment assy and name

- Bucket

- Arm

- Boom

- Swing

- Dozer

- Hydraulic cylinders

- SECTION 11 - UPPER STRUCTURE

- Canopy

- Cab

- Guard

- Floor plate

- Battery

- Counterweight

- Fuel tank

- Hydraulic oil tank

- Air cleaner

- Muffler

- Hydraulic pump

- Radiator

- Engine

- Control valve

- Solenoid valve

- Pilot valve

- Pilot valve travel

- Slew motor

- Joint swivel

- Selector valve

- Upper frame

- SECTION 12 - TRAVEL SYSTEM

- Low structure

- Crawler

- Slide plate

- Roller tracks

- Idler adjuster

- Sprocket

- Travel motor

- Slew bearing

- Lower frame

- SECTION 13 - TROUBLESHOOTING HYDRAULIC SYSTEM

- General precautions

- Trouble diagnosis: Hydraulic

- Troubleshooting

- SECTION 14 - TROUBLESHOOTING ELECTRICAL SYSTEM

- Trouble diagnosis: Electrical

- Troubleshooting

- SECTION 15 - TROUBLESHOOTING ENGINE

- Trouble diagnosis: Engine

- Troubleshooting

- SECTION 16 - ENGINE

- Specifications and Performance

- Cross-Sectional Views

- Cooling water, lubricating oil, and fuel oil

- Troubleshooting

- Measuring instruments

- Measurement, inspection, and adjustment

- Adjustment the valve head clearance

- Checking the v-belt tension

- Measuring and checking the injection pressure and spray patterns of the fuel injection valve

- Checking and adjustment the fuel injection timing

- Adjustment the no-load maximum (or minimum) revolutions

- Checking the cooling water system and radiator for water leakage

- Checking the battery

- Checking the sensors

- Checking the oil cooler

- Checking the piston cooling nozzle

- Measuring Procedure, Service Data, and Corrective Action

- Disassembly and reassembly

- Service data

- Tightening torque

- Fuel injection pump for indirect injection system

- Fuel Injection Pump for Direct Injection System

- Governor

- Turbocharger

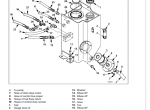

Screenshots for New Holland E16 - E18 Excavators Workshop Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for New Holland E16 - E18 Excavators Workshop Manual PDF:

eTimGo AGCE for CNH EST 2025 all brands OFFLINE

eTimGo AGCE for CNH EST 05/2025 all brands OFFLINE. Manuals, electrical bulletin diagrams, and diagnostic procedures are provided, including some spare parts catalogs.

1200$

[05/2025]

|

New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software![Diagnostic Software New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software](https://www.epcatalogs.com/file/base/7wA2eiQzaw96Mud+nQLe62FMZmZxTTk819fwjKwFzn9gZlueS7pErMi5cA5I4B9rnJjvyM2KHVeYq8dAqLFqg6eVylUigwGA14M6GWQO8C:2FaqSq5rLX38HGZjM8wALuylflj8yTHY6HQGzotXlCesqQ=/case-new-holland-electronic-service-tools-cnh-est-software-download.png)

The dealer software Electronic Service Tools CNH EST 9.13 update 3 (ex v9.3, v9.4, v9.5, 9.6, 9.7) with the highest engineering access Level available for download or shipping worldwide with online support!

250$

[01/2026]

|

Original CNH DPA5 Diagnostic Service Tool Adapter Cable Kit + CNH EST 9.12

The Case, New Holland (CNH) DPA5 adapter kit includes all the cables. This is a genuine CNH DPA5 kit. Include CNH 9.12 Engineering Software 2025

1699$

[2025]

|

CNH Display Codes for the Paid Features 2023 v1.1

The app generates codes for CNH displays to unlock paid features. Codes are entered through the display

3999$

[2024]

|