![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Detroit Diesel MBE Series Set of PDF Manuals

[]This set includes following PDF files:

- Detroit Diesel MBE 4000 Service Manual (6SE412).

This manual contains complete instructions on operation, adjustment (tune-up), preventive maintenance, and repair (including complete overhaul) for the MBE 4000 engine. This manual was written primarily for persons servicing and overhauling the engine.

- Detroit Diesel Application and Installation Manual DDEC VI (7SA827).

This document is a guideline for qualified personnel. It is intended to be used by vehicle manufacturers and contains Detroit Diesel Corporation's recommendations for the ancillary systems supporting the Detroit Diesel engines covered by this document.

- Detroit Diesel Troubleshooting Guide MBE 4000 DDEC VI (6SE568).

This manual contains mechanical troubleshooting procedures and instructions for troubleshooting the electronic controls.

- Detroit Diesel MBE EGR Technician's Guide.

This guide was created to provide qualified service technicians with a detailed explanation of the Exhaust Gas Recirculation (EGR) system to facilitate quicker and more effective diagnosing of MBE EGR related issues.

- Detroit Diesel Troubleshooting Guide MBE Electronic Controls (6SE422).

This manual provides instruction for troubleshooting the MBE Electronics System.

This set includes PDF files. We recommend to use Adobe PDF Reader, to be sure all images / graphics will display correctly.

Contents of service manual:

- GENERAL INFORMATION

- SCOPE AND USE OF THIS MANUAL

- GENERAL DESCRIPTION

- ELECTRONIC ENGINE CONTROL SYSTEM

- ENGINE BRAKING POWER

- GENERAL SPECIFICATIONS AND ENGINE VIEWS

- ENGINE MODEL AND SERIAL NUMBER

- EXHAUST GAS RECIRCULATION (EGR) SYSTEM

- SAFETY INSTRUCTIONS AND PRECAUTIONS

- ENGLISH TO METRIC CONVERSION

- DECIMAL AND METRIC EQUIVALENTS

- TORQUE SPECIFICATIONS

- 1 ENGINE

- 1.1 CYLINDER HEAD COVER

- 1.2 CYLINDER HEAD

- 1.3 CYLINDER BLOCK

- 1.4 EGR CYLINDER HEAD AND BLOCK

- 1.5 EGR FRONT AND REAR LIFTER BRACKETS

- 1.6 ENGINE BRAKE

- 1.7 FRONT RADIAL SEAL

- 1.8 REAR RADIAL SEAL

- 1.9 CRANKSHAFT ASSEMBLY

- 1.10 FRONT COVER HOUSING

- 1.11 CRANKSHAFT VIBRATION DAMPER

- 1.12 FLYWHEEL

- 1.13 RING GEAR

- 1.14 PILOT BEARING

- 1.15 ENGINE CRANKING TOOL

- 1.16 FLYWHEEL HOUSING

- 1.17 PISTON, PISTON RING, AND CONNECTING ROD

- 1.18 EGR PISTON, PISTON RING, AND CONNECTING ROD

- 1.19 VALVES

- 1.20 EGR VALVES

- 1.21 ROCKER ARM

- 1.22 CAMSHAFT AND CAMSHAFT SENSOR

- 1.23 EGR CAMSHAFT

- 1.A ADDITIONAL INFORMATION

- 2 FUEL SYSTEM

- 2.1 INJECTOR UNIT PUMP

- 2.2 EGR INJECTOR UNIT PUMP

- 2.3 FUEL INJECTOR LINE

- 2.4 FUEL INJECTOR NOZZLE

- 2.5 EGR FUEL INJECTOR NOZZLE

- 2.6 PROTECTIVE SLEEVE

- 2.7 DDEC ELECTRONIC CONTROL UNIT

- 2.8 FUEL HEAT EXCHANGER

- 2.9 FUEL FILTER

- 2.10 EGR FUEL FILTER

- 2.11 FUEL PUMP

- 2.12 FUEL SYSTEM INSPECTION

- 2.A ADDITIONAL INFORMATION

- 3 LUBRICATION SYSTEM

- 3.1 OIL PAN

- 3.2 OIL SPRAY NOZZLE

- 3.3 EGR CAMSHAFT LUBRICATION SPRAYER

- 3.4 OIL PUMP

- 3.5 EGR OIL PUMP AND PICK UP TUBE

- 3.6 OIL FILTER

- 3.7 OIL HEAT EXCHANGER AND FILTER HOUSING

- 3.8 OIL PRESSURE AND TEMPERATURE SENSOR

- 3.9 ADDITIONAL INFORMATION

- 4 COOLING SYSTEM

- 4.1 COOLING SYSTEM

- 4.2 COOLANT PUMP

- 4.3 EGR COOLANT PUMP

- 4.4 FRONT IDLER AND TENSIONER SUPPORT

- 4.5 THERMOSTAT

- 4.6 EGR THERMOSTAT HOUSING

- 4.7 COOLANT TEMPERATURE SENSOR

- 4.8 ADDITIONAL INFORMATION

- 5 FUEL, LUBRICATING OIL, AND COOLANT

- 5.1 FUEL

- 5.2 LUBRICATING OIL

- 5.3 COOLANT

- 5.A ADDITIONAL INFORMATION

- 6 AIR INTAKE SYSTEM

- 6.1 INTAKE MANIFOLD

- 6.2 CHARGE PRESSURE/TEMPERATURE SENSOR

- 6.3 TURBOCHARGER

- 6.A ADDITIONAL INFORMATION

- 7 EXHAUST SYSTEM

- 7.1 EXHAUST MANIFOLD

- 7.2 EXHAUST BRAKE ASSEMBLY

- 7.3 EGR EXHAUST MANIFOLD

- 7.4 EGR COOLER AND COOLER SUPPORT BRACKET

- 7.5 EGR CONTROL VALVE, GAS OUTLET PIPE, AND GAS MIXER

- 7.6 EPV (ELECTRONIC PROPORTIONAL VALVE) AND WABCO® AIR SOLENOID VALVE

- 7.7 HENGST® BREATHER FILTER

- 7.A ADDITIONAL INFORMATION

- 8 ELECTRICAL EQUIPMENT

- 8.1 DRIVE BELTS

- 8.A ADDITIONAL INFORMATION

- 9 POWER TAKE-OFF

- 9.1 POWER TAKE-OFF

- 10 SPECIAL EQUIPMENT

- 10.1 AIR COMPRESSOR

- 10.A ADDITIONAL INFORMATION

- 11 OPERATION AND VERIFICATION

- 11.1 PREPARATION FOR A FIRST TIME START

- 11.2 STARTING THE ENGINE

- 11.3 RUNNING THE ENGINE

- 11.4 STOPPING THE ENGINE

- 12 ENGINE TUNE-UP

- 12.1 VALVE LASH CHECKING

- 12.2 ADJUSTING VALVE LASH

- 13 PREVENTIVE MAINTENANCE

- 13.1 SCHEDULED INTERVALS

- 14 ENGINE STORAGE

- 14.1 PREPARING ENGINE FOR STORAGE

- 15 MECHANICAL TROUBLESHOOTING

- 15.1 TROUBLESHOOTING THE ELECTRONIC ENGINE CONTROL SYSTEM

- 15.2 GENERAL TROUBLESHOOTING

- INDEX

Contents of application and installation manual:

- 1 INTRODUCTION

- 2 SAFETY PRECAUTIONS

- 2.1 STANDS

- 2.2 GLASSES

- 2.3 WELDING

- 2.4 WORK PLACE

- 2.5 CLOTHING

- 2.6 ELECTRIC TOOLS

- 2.7 AIR

- 2.8 DIAGNOSTIC TOOLS

- 2.9 FLUIDS AND PRESSURE

- 2.10 BATTERIES

- 2.11 FIRE

- 2.12 PAINT

- 2.13 FLUOROELASTOMER

- 3 HARDWARE AND WIRING

- 3.1 MOTOR CONTROL MODULE

- 3.2 COMMON POWERTRAIN CONTROLLER

- 3.3 WIRES AND WIRING

- 3.4 CONDUIT AND LOOM

- 3.5 TAPE AND TAPING

- 3.6 SENSORS

- 3.7 LAMPS

- 4 INPUTS AND OUTPUTS

- 4.1 INPUTS

- 4.2 SWITCH INPUTS RECEIVED OVER J1939 DATA LINK

- 4.3 DIGITAL OUTPUTS – CPC

- 4.4 ANALOG OUTPUTS – CPC

- 4.5 PWM OUTPUT — CPC

- 5 FEATURES

- 5.1 ACCELERATION LIMITER

- 5.2 COLD START – MBE900 AND MBE4000

- 5.3 CRUISE CONTROL

- 5.4 DIAGNOSTICS

- 5.5 DUAL SPEED AXLE

- 5.6 ENGINE BRAKE CONTROLS – MBE900 AND MBE4000

- 5.7 ENGINE BRAKE CONTROLS – SERIES 60

- 5.8 ENGINE PROTECTION

- 5.9 ENGINE STARTER CONTROL

- 5.10 ETHER STARTING – SERIES 60

- 5.11 FAN CONTROL

- 5.12 FLEET MANAGEMENT

- 5.13 FUEL ECONOMY INCENTIVE

- 5.14 IDLE ADJUST

- 5.15 IDLE SHUTDOWN TIMER AND PTO SHUTDOWN

- 5.16 LIMITERS

- 5.17 LOW GEAR TORQUE REDUCTION

- 5.18 OPTIMIZED IDLE

- 5.19 PARKED REGENERATION

- 5.20 PASSMART

- 5.21 PASSWORDS

- 5.22 PROGRESSIVE SHIFT

- 5.23 STARTER LOCKOUT

- 5.24 TACHOMETER DRIVE

- 5.25 THROTTLE CONTROL/GOVERNORS

- 5.26 TRANSMISSION INTERFACE

- 5.27 VEHICLE SPEED LIMITING

- 5.28 VEHICLE SPEED SENSOR ANTI-TAMPERING

- 6 COMMUNICATION PROTOCOLS

- 6.1 OVERVIEW

- 6.2 SAE J1587 DATA LINK

- 6.3 SAE J1939 MESSAGES AND MESSAGE FORMAT

- APPENDIX A: HARNESS WIRING DIAGRAMS

- APPENDIX B: ACRONYMS

- APPENDIX C: PARAMETER LIST

- INDEX

Contents of troubleshooting guide:

- 1 INTRODUCTION

- 1.1 OVERVIEW

- 1.2 SCOPE AND USE OF THIS GUIDE

- 1.3 SAFETY PRECAUTIONS

- 2 FUELINJECTION

- 2.1 PERFORMING TROUBLESHOOTING TESTS

- 2.2 TEST #1: FUEL PRESSURE TEST

- 2.3 TEST #2: PERCENTAGE OF FUEL DELIVERY FOR A SMOOTH IDLE

- 2.4 TEST #4: FUEL PUMP DRIVEN GEAR BOLT TORQUE

- 2.5 TEST #5: LEAK TEST

- 3 MISFIRING CYLINDER

- 3.1 POOR VEHICLE GROUND

- 3.2 AERATED FUEL

- 3.3 IMPROPER VALVE CLEARANCE, WORN OR DAMAGED CAMSHAFT LOBES AND ROLLERS

- 3.4 FAULTY FUEL NOZZLE/UNIT PUMP

- 3.5 FAULTY MCM

- 3.6 WORN OR DAMAGED VALVE OR CYLINDER KIT

- 4 STARTING DIFFICULTY (ENGINE ROTATES)

- 4.1 TROUBLESHOOTING PROCEDURE FOR DDEC-CPC WIRING HARNESS

- 4.2 VEHICLE CIRCUIT BREAKERS OR FUSES CHECK

- 4.3 DDEC-ECU POWER HARNESS VOLTAGE TEST

- 4.4 POWER HARNESS REPAIR

- 4.5 TROUBLESHOOTING PROCEDURE FOR AN EMPTY FUEL TANK

- 4.6 LOW FUEL LEVEL RESOLUTION

- 4.7 TROUBLESHOOTING PROCEDURE FOR LOW BATTERY VOLTAGE

- 4.8 BATTERY REPLACEMENT

- 4.9 TEST ENGINE WITH REPLACED BATTERY

- 4.10 TROUBLESHOOTING PROCEDURE FOR CORRODED OR DAMAGED BATTERY TERMINALS

- 4.11 CORRODED OR DAMAGED BATTERY TERMINAL REPAIR

- 4.12 TROUBLESHOOTING PROCEDURE FOR DEFECTIVE MAGNETIC SWITCH

- 4.13 MAGNETIC SWITCH REPLACEMENT

- 4.14 TROUBLESHOOTING PROCEDURE FOR A DEFECTIVE STARTER

- 4.15 STARTER REPLACEMENT

- 4.16 TROUBLESHOOTING PROCEDURE FOR LOW CRANKING SPEED

- 4.17 LOW CRANKING SPEED REPAIR

- 4.18 TROUBLESHOOTING PROCEDURE FOR THE FUEL SUPPLY VALVE

- 4.19 FUEL SUPPLY VALVE REPAIR

- 4.20 PLUGGED FUEL FILTER(S) REPLACEMENT

- 4.21 TROUBLESHOOTING PROCEDURE FOR FUEL PUMP

- 4.22 FUEL PUMP REPLACEMENT

- 4.23 TROUBLESHOOTING PROCEDURE FOR AERATED FUEL

- 4.24 AERATED FUEL RESOLUTION

- 4.25 TROUBLESHOOTING PROCEDURE FOR RESTRICTIVE AIR FILTER

- 4.26 AIR FILTER REPLACEMENT

- 4.27 TROUBLESHOOTING PROCEDURE FOR LOW COMPRESSION

- 4.28 LOW COMPRESSION REPAIR

- 5 NO START (ENGINE WILL NOT ROTATE)

- 6 EXCESSIVE OIL CONSUMPTION

- 6.1 MISCALIBRATED DIPSTICK

- 6.2 EXTERNAL OIL LEAKS

- 6.3 ENGINE OIL LEAK REPAIR

- 6.4 LEAKING OIL HEAT EXCHANGER

- 6.5 TEST ENGINE WITH NEW OIL HEAT EXCHANGER

- 6.6 DEFECTIVE AIR COMPRESSOR

- 6.7 TEST ENGINE WITH REPAIRED AIR COMPRESSOR

- 6.8 DEFECTIVE TURBOCHARGER

- 6.9 WORN OR DAMAGED VALVE OR CYLINDER KIT

- 6.10 WORN OR DAMAGED VALVE(S) OR CYLINDER KIT(S) REPAIR

- 7 EXCESSIVE CRANKCASE PRESSURE

- 7.1 OBSTRUCTION OR DAMAGE TO BREATHER SYSTEM

- 7.2 DEFECTIVE AIR COMPRESSOR

- 7.3 DEFECTIVE TURBOCHARGER

- 7.4 WORN OR DAMAGED VALVE OR CYLINDER KIT

- 8 EXCESSIVE EXHAUST SMOKE (BLACK OR GRAY)

- 9 EXCESSIVE BLUE SMOKE

- 10 EXCESSIVE WHITE SMOKE

- 11 ROUGH RUNNING OR STALLING

- 12 LACK OF POWER

- 13 HIGH ENGINE COOLANT TEMPERATURE

- 14 LOW OIL PRESSURE

- 15 LOW COOLANT TEMPERATURE

- 16 POOR FUEL ECONOMY

- 17 DDEC VI SYSTEM

- 17.1 DDEC VI SYSTEM--HOW IT WORKS

- 17.2 MOTOR CONTROL MODULE

- 17.3 COMMON POWERTRAIN CONTROLLER

- 17.4 WIRES AND WIRING

- 17.5 CONDUIT AND LOOM

- 17.6 TAPE AND TAPING

- 17.7 SENSORS

- 17.8 INSTRUMENT PANEL LAMPS

- 18 SPN 27 - EGR VALVE POSITION CIRCUIT FAULT

- 18.1 SPN 27/FMI 3

- 18.2 SPN 27/FMI 4

- 18.3 SPN 27/FMI 7

- 19 SPN 51 - INTAKE THROTTLE VALVE ABOVE OR BELOW NORMAL OPERATING RANGE

- 19.1 SPN 51/FMI 2, 3 OR 4

- 20 SPN 70 (CPC) - J1939 PARK BRAKE SWITCH SIGNAL ERRATIC OR MISSING

- 20.1 SPN 70/FMI 13

- 20.2 SPN 70/FMI 19

- 21 SPN 84 (CPC) - J1939 WHEEL-BASED VEHICLE SPEED SIGNAL ERRATIC OR MISSING

- 21.1 SPN 84/FMI 13

- 21.2 SPN 84/FMI 19

- 22 SPN 84 – VEHICLE SPEED SENSOR

- 22.1 SPN 84/FMI 2

- 22.2 SPN 84/FMI 3

- 22.3 SPN 84/FMI 4

- 22.4 SPN 84/FMI 6

- 22.5 SPN 84/FMI 8

- 23 SPN 86 – ADAPTIVE CRUISE CONTROL FAULT

- 23.1 SPN 86/FMI 14

- 24 SPN 91 – ACCELERATOR PEDAL SENSOR FAULT

- 24.1 SPN 91/FMI 2

- 24.2 SPN 91/FMI 3

- 24.3 SPN 91/FMI 4

- 25 SPN 94 – FUEL COMPENSATION PRESSURE SENSOR CIRCUIT FAULT

- 25.1 SPN 94/FMI 3 OR 4

- 26 SPN 100—ENGINE OIL PRESSURE OUTSIDE NORMAL OPERATING RANGE

- 26.1 SPN 100/FMI 1

- 26.2 SPN 100/FMI 2

- 26.3 SPN 100/FMI 3

- 26.4 SPN 100/FMI 4

- 26.5 SPN 100/FMI 18

- 27 SPN 103 – TURBO NO REVOLUTION

- 27.1 SPN 103/FMI 0

- 27.2 SPN 103/FMI 1

- 27.3 SPN 103/FMI 3

- 27.4 SPN 103/FMI 4

- 27.5 SPN 103/FMI 7

- 28 SPN 110—COOLANT TEMPERATURE ABOVE OR BELOW NORMAL OPERATING RANGE

- 28.1 SPN 110/FMI 0

- 28.2 SPN 110/FMI 2

- 28.3 SPN 110/FMI 3

- 28.4 SPN 110/FMI 4

- 28.5 SPN 110/FMI 14

- 29 SPN 111 – COOLANT LEVEL OUTSIDE NORMAL OPERATING RANGE

- 29.1 SPN 111/FMI 1

- 29.2 SPN 111/FMI 3

- 29.3 SPN 111/FMI 4

- 30 SPN 158 — BATTERY CHARGING FAULT

- 30.1 SPN 158/FMI 0

- 30.2 SPN 158/FMI 1

- 30.3 SPN 158/FMI 2

- 31 SPN 168 – BATTERY VOLTAGE OUTSIDE NORMAL OPERATING RANGE

- 31.1 SPN 168/FMI 0

- 31.2 SPN 168/FMI 1

- 32 SPN 174 – SUPPLY FUEL TEMPERATURE FAULT

- 32.1 SPN 174/FMI 3

- 32.2 SPN 174/FMI 4

- 33 SPN 175 – ENGINE OIL TEMPERATURE OUTSIDE NORMAL RANGE

- 33.1 SPN 175/FMI 2

- 33.2 SPN 175/FMI 3

- 33.3 SPN 175/FMI 4

- 34 SPN 190 - ENGINE SPEED HIGH

- 34.1 SPN 190/FMI 2

- 35 SPN 191 (CPC) - J1939 ETC1 MESSAGE MISSING AND TRANSMISSION OUTPUT SHAFT SPEED SIGNAL ERRATIC OR MISSING

- 35.1 SPN 191/FMI 9

- 35.2 SPN 191/FMI 13

- 35.3 SPN 191/FMI 19

- 36 SPN 274 (CPC) – MCM ENGINE HOURS DATA HIGHER OR LOWER THAN EXPECTED

- 36.1 SPN 274/FMI 0

- 36.2 SPN 274/FMI 1

- 37 SPN 411 — EGR DIFFERENTIAL PRESSURE OR DELTA P SENSOR CIRCUIT OUTSIDE OF NORMAL OPERATING RANGE

- 37.1 SPN 411/FMI 0

- 37.2 SPN 411/FMI 1

- 37.3 SPN 411/FMI 3

- 37.4 SPN 411/FMI 4

- 38 SPN 523 (CPC) - TRANSMISSION CURRENT GEAR SIGNAL ERRATIC OR MISSING

- 38.1 SPN 523/FMI 19

- 38.2 SPN 523/FMI 13

- 39 SPN 524 (CPC) - J1939 ETC2 MESSAGE IS MISSING

- 39.1 SPN 523/FMI 9

- 40 SPN 527 (CPC) - J1939 CCVS MESSAGE MISSING

- 40.1 SPN 527/FMI 9

- 41 SPN 558 - IDLE VALIDATION SWITCH

- 41.1 SPN 558/FMI 1

- 41.2 SPN 558/FMI 3

- 41.3 SPN 558/FMI 4

- 42 SPN 596 (CPC) - CRUISE CONTROL ENABLE SWITCH SIGNAL ERRATIC OR MISSING

- 42.1 SPN 596/FMI 13

- 42.2 SPN 596/FMI 19

- 43 SPN 597 (CPC) - SERVICE BRAKE SWITCH SIGNAL ERRATIC OR MISSING

- 43.1 SPN 597/FMI 13

- 43.2 SPN 597/FMI 19

- 44 SPN 599 - CRUISE CONTROL SWITCHES NOT FUNCTIONING PROPERLY

- 44.1 SPN 599/FMI 4

- 45 SPN 600 (CPC) - CRUISE CONTROL COAST SWITCH SIGNAL ERRATIC OR MISSING

- 45.1 SPN 600/FMI 13

- 45.2 SPN 600/FMI 19

- 46 SPN 602 (CPC) - CRUISE CONTROL ACCELERATE SWITCH SIGNAL ERRATIC OR MISSING

- 46.1 SPN 602/FMI 13

- 46.2 SPN 602/FMI 19

- 47 SPN 609 - MCM FAULT (ERRONEOUS DATA)

- 47.1 SPN 609/FMI 12

- 47.2 SPN 609/FMI 14

- 48 SPN 615 - INTAKE AIR DELTA PRESSURE OUTSIDE OF NORMAL OPERATING RANGE

- 48.1 SPN 615/FMI 3

- 48.2 SPN 615/FMI 4

- 49 SPN 615 (CPC) - J1939 DM1 MESSAGE FROM TRANSMISSION MISSING

- 49.1 SPN 615/FMI 9

- 50 SPN 625 - CAN FAULT

- 50.1 SPN 625/FMI 2

- 50.2 SPN 625/FMI 4

- 51 SPN 628 (CPC) - MULTIPLE FAULTS

- 51.1 SPN 628/FMI 13 (ALL FAULT DESCRIPTIONS)

- 51.2 SPN 628/FMI 14

- 52 SPN 629 (CPC) - MULTIPLE FAULTS

- 52.1 SPN 629/FMI 2

- 52.2 SPN 629/FMI 12

- 53 SPN 630 (CPC) - MULTIPLE FAULTS

- 53.1 SPN 630/FMI 14

- 54 SPN 636 — CRANKSHAFT POSITION SENSOR OUTSIDE OF NORMAL OPERATING CONDITIONS

- 54.1 SPN 636/FMI 1

- 54.2 SPN 636/FMI 3

- 54.3 SPN 636/FMI 4

- 54.4 SPN 636/FMI 7

- 54.5 SPN 636/FMI 8

- 55 SPN 651 – INJECTOR #1 NOT OPERATING NORMALLY

- 55.1 SPN 651/FMI 5

- 55.2 SPN 651/FMI 10

- 56 SPN 652 – INJECTOR #2 NOT OPERATING NORMALLY

- 56.1 SPN 652/FMI 5

- 56.2 SPN 652/FMI 10

- 57 SPN 653 – INJECTOR #3 NOT OPERATING NORMALLY

- 57.1 TROUBLESHOOTING SPN 653/FMI 5

- 57.2 TROUBLESHOOTING SPN 653/FMI 10

- 58 SPN 654 – INJECTOR #4 NOT OPERATING NORMALLY

- 58.1 TROUBLESHOOTING SPN 654/FMI 5

- 58.2 TROUBLESHOOTING SPN 654/FMI 10

- 59 SPN 655 – INJECTOR #5 NOT OPERATING NORMALLY

- 59.1 SPN 655/FMI 5

- 59.2 SPN 655/FMI 10

- 60 SPN 656 – INJECTOR #6 NOT OPERATING NORMALLY

- 60.1 SPN 656/FMI 5

- 60.2 SPN 656/FMI 10

- 61 SPN 701 - CONSTANT THROTTLE VALVE (AUX PWM #7) NOT OPERATING NORMALLY

- 61.1 SPN 701/FMI 3

- 61.2 SPN 701/FMI 4

- 61.3 SPN 701/FMI 5

- 62 SPN 703 (CPC) - ASG2 BACKUP LAMP

- 62.1 SPN 703/FMI 3

- 62.2 SPN 703/FMI 4

- 63 SPN 704 (CPC) - HIGH EXHAUST SYSTEM TEMPERATURE LAMP

- 63.1 SPN 704/FMI 3

- 63.2 SPN 704/FMI 4

- 64 SPN 705 (CPC) - MALFUNCTION INDICATOR LAMP

- 64.1 SPN 705/FMI 3

- 64.2 SPN 705/FMI 4

- 65 SPN 706 (CPC) - ASG2 CHECK TRANS TEMP LAMP

- 65.1 SPN 706/FMI 3

- 65.2 SPN 706/FMI 4

- 66 SPN 706 - ELECTRONIC PROPORTIONING VALVE CONTROL #2 NOT OPERATING NORMALLY

- 66.1 SPN 706/FMI 3

- 66.2 SPN 706/FMI 4

- 66.3 SPN 706/FMI 5

- 67 SPN 707 (CPC) - AMBER WARNING LAMP

- 67.1 SPN 707/FMI 3

- 67.2 SPN 707/FMI 4

- 68 SPN 708 (CPC) - ASG2 CHECK TRANS LAMP

- 68.1 SPN 708/FMI 3

- 68.2 SPN 708/FMI 4

- 69 SPN 709 - SINGLE-SPEED FAN (LOW-SIDE DIGITAL OUTPUT #3) FAULT

- 69.1 SPN 709/FMI 3

- 69.2 SPN 709/FMI 4

- 69.3 SPN 709/FMI 5

- 70 SPN 710 - ELECTRONIC PROPORTIONING VALVE 1 (ENTRY SHUTOFF FLAP) NOT OPERATING NORMALLY

- 70.1 SPN 710/FMI 3

- 70.2 SPN 710/FMI 4

- 70.3 SPN 710/FMI 5

- 71 SPN 711 (CPC) - DPF REGEN LAMP

- 71.1 SPN 711/FMI 3

- 71.2 SPN 711/FMI 4

- 72 SPN 713 (CPC) - TOP2 LOCKOUT SOLENOID

- 72.1 SPN 713/FMI 3

- 72.2 SPN 713/FMI 4

- 72.3 SPN 713/FMI 5

- 72.4 SPN 713/FMI 7

- 73 SPN 714 (CPC) - TOP2 SHIFT SOLENOID

- 73.1 SPN 714/FMI 3

- 73.2 SPN 714/FMI 4

- 73.3 SPN 714/FMI 5

- 74 SPN 715 (CPC) - VEHICLE POWER SHUTDOWN

- 74.1 SPN 715/FMI 3

- 74.2 SPN 715/FMI 4

- 74.3 SPN 715/FMI 5

- 75 SPN 729 - GRID HEATER NOT OPERATING NORMALLY

- 75.1 SPN 729/FMI 3

- 75.2 SPN 729/FMI 4

- 76 SPN 723 — CAMSHAFT POSITION SENSOR FAULT

- 76.1 SPN 723/FMI 3

- 76.2 SPN 723/FMI 4

- 76.3 SPN 723/FMI 8

- 76.4 SPN 723/FMI 14

- 77 SPN 904 (CPC) - J1939 EBC2 MESSAGE MISSING AND FRONT AXLE SPEED SIGNAL ERRATIC OR MISSING

- 77.1 SPN 904/FMI 9

- 77.2 SPN 904/FMI 13

- 77.3 SPN 904/FMI 19

- 78 SPN 973 (CPC) - J1939 EBC1 MESSAGE MISSING AND ENGINE RETARDER SELECTION SIGNAL IS ERRATIC OR MISSING

- 78.1 SPN 973/FMI 9

- 78.2 SPN 973/FMI 13

- 78.3 SPN 973/FMI 19

- 79 SPN 975 - TWO-SPEED FAN (AUX PWM #6) FAULT

- 79.1 SPN 975/FMI 3

- 79.2 SPN 975/FMI 4

- 79.3 SPN 975/FMI 5

- 80 SPN 986 (CPC) - J1939 CM1 MESSAGE IS MISSING

- 80.1 SPN 986/FMI 9

- 81 SPN 1172 -TURBO COMPRESSOR IN TEMP HIGH OR LOW

- 81.1 SPN 1172/FMI 3

- 81.2 SPN 1172/FMI 4

- 82 SPN 1176 - TURBO COMPRESSOR INLET PRESSURE OUTSIDE NORMAL RANGE

- 82.1 SPN 1176/FMI 3

- 82.2 SPN 1176/FMI 4

- 83 SPN 1188 - WASTEGATE VALVE CONTROL (AUX PWM #10)

- 83.1 SPN 1188/FMI 3

- 83.2 SPN 1188/FMI 4

- 83.3 SPN 1188/FMI 5

- 84 SPN 1590 (CPC) - J1939 ACC1 MESSAGE FROM ADAPTIVE CRUISE CONTROL IS MISSING

- 84.1 SPN 1590/FMI 9

- 85 SPN 1624 (CPC) - J1939 TCO1 MESSAGE IS MISSING AND TACHOGRAPH VEHICLE SPEED SIGNAL IS ERRATIC AND MISSING

- 85.1 SPN 1624/FMI 9

- 85.2 SPN 1624/FMI 13

- 85.3 SPN 1624/FMI 19

- 86 SPN 1636 – INTAKE MANIFOLD TEMPERATURE OUTSIDE OF NORMAL OPERATING RANGE

- 86.1 SPN 1636/FMI 2

- 86.2 SPN 1636/FMI 3

- 86.3 SPN 1636/FMI 4

- 86.4 SPN 1636/FMI 14

- 87 SPN 1716 (CPC) - J1939 ERC1 MESSAGE IS MISSING

- 87.1 SPN 1716/FMI 9

- 88 SPN 1845 (CPC) - J1939 TCFG2 MESSAGE IS MISSING

- 88.1 SPN 1845/FMI 9

- 89 SPN 2623 (CPC) - PWM ACCELERATOR PEDAL GAS1 AND GAS2 SIGNAL MISSING

- 89.1 SPN 2623/FMI 4

- 89.2 SPN 2623/FMI 14

- 90 SPN 2791 – EGR VALVE (AUX PWM #1) FAILED OR OPEN CIRCUIT

- 90.1 SPN 2791/FMI 3

- 90.2 SPN 2791/FMI 4

- 90.3 SPN 2791/FMI 5

- 91 SPN 2795 - CAN COMMUNICATION ERROR

- 91.1 SPN 2795/FMI 9

- 92 SPN 2900 (CPC) - J1939 ETC7 MESSAGE IS MISSING

- 92.1 SPN 2900/FMI 9

- 93 SPN 3242 - DOC INLET TEMPERATURE SENSOR ABOVE OR BELOW NORMAL OPERATING RANGE

- 93.1 SPN 3242/FMI 2, 3, 4 OR 10

- 94 SPN 3246 - DPF OUTLET TEMPERATURE SENSOR OPERATING ABOVE OR BELOW NORMAL

- 94.1 SPN 3246/FMI 0, 2, 3, 4, 10, 14, 31

- 95 SPN 3250 - DPF INLET TEMPERATURE SENSOR ABOVE OR BELOW NORMAL OPERATING RANGE

- 95.1 SPN 3250/FMI 0, 2, 3, 4, 10, 14, 31

- 96 SPN 3251 - DPF OUTLET PRESSURE ABOVE OR BELOW NORMAL OPERATING RANGE

- 96.1 SPN 3251/FMI 0, 1 OR 16

- 97 SPN 3471 - ELECTRONIC DOSING VALVE SENSOR ABOVE OR BELOW NORMAL OPERATING RANGE

- 97.1 SPN 3471/FMI 1, 3, 4 OR 5

- 98 SPN 3480 - FUEL LINE PRESSURE SENSOR ABOVE OR BELOW NORMAL OPERATING RANGE

- 98.1 SPN 3480/FMI 1, 2 OR 14

- 99 SPN 3482 - FUEL CUTOFF VALVE SENSOR ABOVE OR BELOW NORMAL OPERATING RANGE

- 99.1 SPN 3482/FMI 3, 4, 5 OR 7

- 100 SPN 3509 - MULTIPLEXER 1 CHANNEL 1 OR 2 SHORT OR OPEN CIRCUIT HIGH

- 100.1 SPN 3509/FMI 3

- 101 SPN 3510 - MULTIPLEXER 2 CHANNEL 1 OR 2 SHORT OR OPEN CIRCUIT HIGH

- 101.1 SPN 3510/FMI 3

- 102 SPN 3510 — ACCELERATOR PEDAL SUPPLY OUTSIDE OF NORMAL OPERATING RANGE

- 102.1 SPN 3510/FMI 2

- 102.2 SPN 3510/FMI 3

- 102.3 SPN 3510/FMI 4

- 103 SPN 3511 - MULTIPLEXER 3 CHANNEL 1 0R 2 SHORT OR OPEN CIRCUIT HIGH

- 103.1 SPN 3511/FMI 3

- 104 SPN 3556 - ELECTRONIC DOSING VALVE ABOVE OR BELOW NORMAL OPERATING RANGE

- 104.1 SPN 3556/FMI 0 OR 1

- 105 SPN 3563 – INTAKE MANIFOLD PRESSURE OUTSIDE NORMAL RANGE

- 105.1 SPN 3563/FMI 0/1/2

- 105.2 SPN 3563/FMI 3

- 105.3 SPN 3563/FMI 4

- 106 SPN 3603 (CPC) - J1939 ESS MESSAGE IS MISSING

- 106.1 SPN 3603/FMI 9

- 107 SPN 3609 - DPF INLET PRESSURE SENSOR ABOVE OR BELOW NORMAL OPERATING RANGE

- 107.1 SPN 3609FMI 2, 3, 4, 10, 20 OR 21

- 108 SPN 3610 - DPF OUTLET PRESSURE SENSOR ABOVE OR BELOW NORMAL OPERATING RANGE

- 108.1 SPN 3610/FMI 2, 3, 4, 14, 20 OR 21

- 109 SPN 3659 — ELECTRONIC UNIT PUMP #1 NOT OPERATING NORMALLY

- 109.1 SPN 3659/FMI 5

- 109.2 SPN 3659/FMI 10

- 110 SPN 3660 - ELECTRONIC UNIT PUMP #2 NOT OPERATING NORMALLY

- 110.1 SPN 3660/FMI 5

- 110.2 SPN 3660/FMI 10

- 111 SPN 3661 - ELECTRONIC UNIT PUMP #3 NOT OPERATING NORMALLY

- 111.1 SPN 3661/FMI 5

- 111.2 SPN 3661/FMI 10

- 112 SPN 3662 - ELECTRONIC UNIT PUMP #4 NOT OPERATING NORMALLY

- 112.1 SPN 3662/FMI 5

- 112.2 SPN 3662/FMI 10

- 113 SPN 3663 - ELECTRONIC UNIT PUMP #5 NOT OPERATING NORMALLY

- 113.1 SPN 3663/FMI 5

- 113.2 SPN 3663/FMI 10

- 114 SPN 3664 - ELECTRONIC UNIT PUMP #6 NOT OPERATING NORMALLY

- 114.1 SPN 3664/FMI 5

- 114.2 SPN 3664/FMI 10

- 115 SPN 3695 (CPC) - DPF REGEN MUX SWITCH MESSAGES NOT OPERATING NORMALLY

- 115.1 SPN 3695/FMI 9

- 115.2 SPN 3695/FMI 13

- 115.3 SPN 3695/FMI 14

- 115.4 SPN 3695/FMI 19

- 116 SPN 3719 - SOOT LEVEL ABOVE NORMAL

- 116.1 SPN 3719/FMI 0, 15,16,OR 31

- 117 SPN 3720 - ASH LEVEL ABOVE NORMAL

- 117.1 SPN 3720/FMI 15 OR 16

- 118 SPN 4077 FUEL LINE PRESSURE SENSOR CIRCUIT FAULT

- 118.1 SPN 4077/FMI 3, 4 OR 14

- 119 SPN 4227 - ELECTROSTATIC OIL SEPARATOR OUTSIDE OF NORMAL OPERATING RANGE

- 119.1 SPN 4227/FMI 3

- 119.2 SPN 4227/FMI 4

Contents of technician's guide:

- 1 INTRODUCTION

- 1.1 VEHICLE INSPECTION

- 1.2 OPERATOR INFORMATION

- 1.3 TROUBLESHOOTING TIPS

- 2 COMPONENTS

- 2.1 MBE 4000 ENGINES WITH EGR SYSTEMS

- 2.2 MBE 900 ENGINES WITH EGR SYSTEMS

- 3 EGR OPERATION

- 4 CODES

- 4.1 DIAGNOSTIC TROUBLESHOOTING

- 4.2 CODE DESCRIPTIONS

- 4.3 TROUBLESHOOTING OF PERFORMANCE CODES

- 4.4 ENGINE PROTECTION

- 5 TESTING

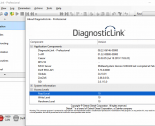

- 6 DETROIT DIESEL DIAGNOSTIC LINK/SNAPSHOTS

- 6.1 WORKING WITH DDDL SNAPSHOTS

- 6.2 USING SNAPSHOT REPLAY CONTROLS

- 6.3 E-MAILING SNAPSHOT FILE

- 7 SNAPSHOT EXAMPLES

- 7.1 NORMAL ENGINE OPERATION SNAPSHOTS

- 7.2 PROBLEM ENGINE OPERATION SNAPSHOTS

- APPENDIX A: LIST OF ACRONYMS

- APPENDIX B: MBE DDEC WIRING SCHEMATICS

- APPENDIX C: SERVICE INFORMATION LETTERS

Contents of troubleshooting guide (Electronic Controls):

- 1 INTRODUCTION

- 1.1 INTRODUCTION

- 1.2 TROUBLESHOOTING INFORMATION

- 1.3 SAFETY PRECAUTIONS

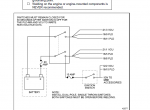

- 2 ELECTRONIC COMPONENTS AND WIRING SCHEMATICS

- 2.1 OVERVIEW

- 2.2 PLD-MR – ENGINE-RESIDENT CONTROL UNIT

- 2.3 VEHICLE CONTROL UNIT— ON-HIGHWAY

- 2.4 WIRES AND WIRING

- 2.5 CONDUIT AND LOOM

- 2.6 TAPE AND TAPING

- 2.7 SENSORS

- 2.8 GRID HEATER

- 2.9 CRUISE CONTROL CIRCUIT

- 2.10 ENGINE FAN

- 2.11 PARKING BRAKE SWITCH

- 2.12 VEHICLE POWER SHUTDOWN — OPTIONAL

- 2.13 STARTER LOCKOUT

- 2.14 ACCELERATOR PEDAL INSTALLATION

- 3 OPERATION

- 3.1 FEATURES

- 4 PID45

- 4.1 DESCRIPTION OF PID 45 – COLD START (GRID HEATER) FAULT

- 4.2 TROUBLESHOOTING PID 45

- 5 PID84

- 5.1 DESCRIPTION OF PID 84 — VEHICLE SPEED SENSOR FAULT

- 5.2 TROUBLESHOOTING PID 84

- 6 PID91

- 6.1 DESCRIPTION OF PID 91 – ACCELERATOR PEDAL SENSOR FAULT

- 6.2 TROUBLESHOOTING PID 91

- 7 PID100

- 7.1 DESCRIPTION OF PID 100 – ENGINE OIL PRESSURE OUTSIDE OF NORMAL OPERATING RANGE

- 7.2 TROUBLESHOOTING PID 100

- 8 PID102

- 8.1 DESCRIPTION OF PID 102 – TURBO BOOST PRESSURE OUTSIDE OF NORMAL OPERATING RANGE

- 8.2 TROUBLESHOOTING PID 102

- 9 PID103

- 9.1 DESCRIPTION OF PID 103 – TURBO NO REVOLUTION FAULT

- 9.2 TROUBLESHOOTING PID 103

- 10 PID 105

- 10.1 DESCRIPTION OF PID 105 – INTAKE AIR TEMPERATURE OUTSIDE OF NORMAL OPERATING RANGE

- 10.2 TROUBLESHOOTING PID 105

- 11 PID 110

- 11.1 DESCRIPTION OF PID 110 – COOLANT TEMPERATURE ABOVE RECOMMENDED NORMAL OPERATING RANGE

- 11.2 TROUBLESHOOTING PID 110

- 12 PID 111

- 12.1 DESCRIPTION OF PID 111 – COOLANT OUTSIDE NORMAL OPERATING RANGE

- 12.2 TROUBLESHOOTING PID 111

- 13 PID 158

- 13.1 DESCRIPTION OF PID 158 — BATTERY CHARGING FAULT

- 13.2 TROUBLESHOOTING PID 158

- 14 PID 168

- 14.1 DESCRIPTION OF PID 168 — BATTERY VOLTAGE OUTSIDE NORMAL OPERATING RANGE

- 14.2 TROUBLESHOOTING PID 168

- 15 PID 174

- 15.1 DESCRIPTION OF PID 174 – SUPPLY FUEL TEMPERATURE SENSOR FAULT

- 15.2 TROUBLESHOOTING PID 174

- 16 PID 175

- 16.1 DESCRIPTION OF PID 175 – ENGINE OIL TEMPERATURE OUTSIDE OF NORMAL OPERATING RANGE

- 16.2 TROUBLESHOOTING PID 175

- 17 PID 190

- 17.1 DESCRIPTION OF PID 190 – ENGINE SPEED OUTSIDE NORMAL OPERATING RANGE

- 17.2 TROUBLESHOOTING PID 190

- 18 SIDS 1–6

- 18.1 DESCRIPTION OF SIDS 1–6 INJECTOR UNIT PUMP NOT OPERATING IN A NORMAL MANNER

- 18.2 TROUBLESHOOTING SIDS 1–6

- 19 SID 21

- 19.1 DESCRIPTION OF SID 21 – CRANKSHAFT POSITION SENSOR OUTSIDE OF NORMAL OPERATING CONDITIONS

- 19.2 TROUBLESHOOTING SID 21

- 20 SID 57

- 20.1 DESCRIPTION OF SID 57 — EXHAUST BRAKE FAULT

- 20.2 TROUBLESHOOTING SID 57

- 21 SID 58

- 21.1 DESCRIPTION OF SID 58 – ENGINE BRAKE FAULT

- 21.2 TROUBLESHOOTING SID 58

- 22 SID 59

- 22.1 DESCRIPTION OF SID 59 – DUAL-SPEED FAN LOW STAGE OPERATION FAULT

- 22.2 TROUBLESHOOTING SID 59

- 23 SID 60

- 23.1 DESCRIPTION OF SID 60 – DUAL-SPEED FAN HIGH STAGE OPERATION FAULT

- 23.2 TROUBLESHOOTING SID 60

- 24 SID 64

- 24.1 DESCRIPTION OF SID 64 — CAMSHAFT POSITION SENSOR FAULT

- 24.2 TROUBLESHOOTING SID 64

- 25 SID 146

- 25.1 DESCRIPTION OF SID 146 EGR SYSTEM FAULT

- 25.2 TROUBLESHOOTING SID 146

- 26 SID 230

- 26.1 DESCRIPTION OF SID 230 – THROTTLE CONTROL FAULT

- 26.2 TROUBLESHOOTING SID 230

- 27 SID 232

- 27.1 DESCRIPTION OF SID 232 – ACCELERATOR PEDAL SUPPLY VOLTAGE FAULT

- 27.2 TROUBLESHOOTING SID 232

- 28 SID 233

- 28.1 DESCRIPTION OF SID 233 – PLD-MR FAULT (ERRONEOUS DATA)

- 28.2 TROUBLESHOOTING SID 233

- 29 SID 242

- 29.1 DESCRIPTION OF SID 242 – CRUISE CONTROL SET/RESUME SWITCH FAULT

- 29.2 TROUBLESHOOTING SID 242

- 30 SID 243

- 30.1 DESCRIPTION OF SID 243 — CRUISE CONTROL SET AND RESUME SWITCH FAULT

- 30.2 TROUBLESHOOTING SID 243

- 31 SID 248

- 31.1 DESCRIPTION OF SID 248 – PLD-MR DDEC-VCU DATALINK FAULT

- 31.2 TROUBLESHOOTING SID 248

- 32 SID 254

- 32.1 DESCRIPTION OF SID 254 – DDEC-VCU FAULT

- 32.2 TROUBLESHOOTING SID 254

Screenshots for Detroit Diesel MBE Series Set of PDF Manuals:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Detroit Diesel MBE Series Set of PDF Manuals:

Detroit Diesel Diagnostic Link 8.23 SP2 (replaces DDDL 8.13, 8.14) Offline Professional

Detroit Diesel DiagnosticLink 8.23 SP2 Professional Offline 01/2026 ALL Grayed Parameters Enabled. Hardware Level 10. Download & Remote Support

200$

[01/2026]

|

Detroit Diesel Reprograming System 7.11

Program Detroit Diesel Reprograming System 7.11 is designed to perform all diagnostic operations for systems programming lineup in 2007 and 2011.

250$

[07/2013]

|

Detroit Diesel Diagnostic Link 7.11 (DDDL 7.11 / 6.50)

Program for diagnostic Detroit Diesel Diagnostic Link 7.11 (DDDL 7.11 / 6.50) intended for serve and diagnose Detroit Diesel

100$

[12/2013]

|

Detroit Diesel Reprogramming Software 7.09 (DDRS 7.09)

Detroit Diesel Reprogramming Software 7.09 (DDRS 7.09) is the electronic tool for servicing Detroit Diesel

150$

[09/2012]

|