![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Detroit Diesel Series 60 Diesel / Natural Gas-Fueled / Diesel Marine Engines Service Manual PDF

[11/2002]Detailed description

On our site, you have the opportunity to purchase a PDF version of the service manual for Detroit Diesel series 60, Natural Gas-Fueled and Diesel Marine Engines via instant download. After purchase, you will receive an e-mail with a download link with detailed recommendations and a description of all the details.

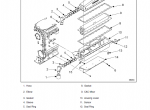

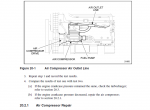

This manual contains maintenance instructions for automotive, industrial, marine, and gas installations with Detroit Diesel series 60. This guide provides a basic overview of each major component and system, as well as recommendations for removing, cleaning, checking, replacing, repairing and installing, and troubleshooting mechanical problems. The manual also contains instructions for maintenance and operation, diagrams, pictures and schemes for a specific engine or component.

Besides, this manual contains complete instructions for operating, setting up, preventative maintenance and repair (including a complete overhaul) of Detroit Diesel 60 Series diesel engines. Below you can read the detailed contents of the service manual.

Repair manual was written primarily for those servicing and repairing the engine. Also, this manual contains all the instructions with step-by-step recommendations and pictures necessary for operators and users. Basic maintenance and overhaul procedures are common to all Detroit Diesel Series 60 engines and apply to all engine models.

You can easily use a PDF document with any Windows, Android, Linux, iOS, MacOS device. The PDF format is available on laptops, PCs, tablets and even smartphones. You can also print the entire document or individual pages, or view this manual in electronic form. To get started with a digital version of a PDF document, you need to install a program or an Adobe Acrobat PDF Reader application. We recommend downloading the latest version. This manual supports English.

CONTENTS:

- GENERAL INFORMATION

- SCOPE AND USE OF THIS MANUAL

- CLEARANCE OF NEW PARTS AND WEAR LIMITS

- THE FOUR CYCLE PRINCIPLE FOR DIESEL ENGINES

- FOUR CYCLE PRINCIPLE FOR NATURAL GAS ENGINES

- GENERAL DESCRIPTION

- GENERAL SPECIFICATIONS

- GENERAL SPECIFICATIONS FOR THE SERIES 60G ENGINE

- ENGINE MODEL, SERIAL NUMBER AND OPTION LABEL

- ENGINE MODEL, SERIAL NUMBER AND OPTION LABEL (SERIES 60G ENGINE)

- REPLACING AND REPAIRING

- DISASSEMBLY

- CLEANING

- SAFETY PRECAUTIONS

- FLUOROELASTOMER (VITON) CAUTION

- ENGINE VIEWS

- ENGLISH TO METRIC CONVERSION

- DECIMAL AND METRIC EQUIVALENTS

- SPECIFICATIONS

- 1 ENGINE

- 1.1 CYLINDER BLOCK AND CYLINDER LINER

- 1.2 CYLINDER HEAD

- 1.3 VALVE AND INJECTOR OPERATING MECHANISM

- 1.4 VALVES, SPRINGS, GUIDES, INSERTS, SEALS AND ROTATORS

- 1.5 ENGINE LIFTER BRACKETS

- 1.6 ROCKER COVER

- 1.7 CRANKSHAFT

- 1.8 CRANKSHAFT OIL SEALS

- 1.9 CRANKSHAFT MAIN BEARINGS

- 1.10 GEAR CASE COVER

- 1.11 GEAR CASE

- 1.12 CRANKSHAFT VIBRATION DAMPER

- 1.13 CRANKSHAFT PULLEY

- 1.14 FLYWHEEL

- 1.15 RING GEAR

- 1.16 FLYWHEEL HOUSING

- 1.17 PISTON AND PISTON RING

- 1.18 FORGED STEEL ONE PIECE PISTON ASSEMBLY AND PISTON RING

- 1.19 PISTON AND CONNECTING ROD ASSEMBLY

- 1.20 CONNECTING ROD

- 1.21 CYLINDER LINER

- 1.22 GEAR TRAIN AND ENGINE TIMING

- 1.23 THRUST PLATE PERIMETER SEAL

- 1.24 CAMSHAFT AND CAMSHAFT BEARING

- 1.25 CAMSHAFT DRIVE GEAR

- 1.26 ADJUSTABLE IDLER GEAR ASSEMBLY

- 1.27 BULL GEAR AND CAMSHAFT IDLER GEAR ASSEMBLY

- 1.28 CRANKSHAFT TIMING GEAR AND TIMING WHEEL

- 1.29 ACCESSORY DRIVE

- 1.30 JAKE BRAKE®

- 1.A ADDITIONAL INFORMATION

- 2 FUEL SYSTEM

- 2.1 DIESEL FUEL SYSTEM OVERVIEW

- 2.2 VEHICLE SAFETY FOR THE NATURAL GAS ENGINE

- 2.3 ELECTRONIC UNIT INJECTOR

- 2.4 FUEL INJECTOR TUBE AND O-RING

- 2.5 N3 ELECTRONIC UNIT INJECTOR

- 2.6 FUEL INJECTOR TUBE

- 2.7 FUEL PUMP WITH SEPARATE DRIVE SHAFT AND HUB

- 2.8 FUEL PUMP WITH ONE-PIECE DRIVE SHAFT AND HUB ASSEMBLY

- 2.9 FUEL PUMP DRIVE

- 2.10 DIESEL FUEL FILTERS (SPIN-ON)

- 2.11 FUEL PRO 380/380E FUEL FILTER SYSTEM

- 2.12 SEA PRO 150/300 DIESEL FUEL PROCESSOR SYSTEM (MARINE)

- 2.13 SEA PRO 152 FUEL FILTER SYSTEM (MARINE ENGINE)

- 2.14 FUEL FILTER TYPE FOR THE SERIES 60G ENGINE

- 2.15 FUEL COOLER (HEAT EXCHANGER-COOLED MARINE ENGINE)

- 2.16 ASSEMBLY FUEL FILTER AND WATER SEPARATOR

- 2.17 ELECTRONIC ENGINE CONTROL

- 2.18 DDEC V ELECTRONIC CONTROL UNIT

- 2.19 DDEC III/IV ELECTRONIC CONTROL MODULE

- 2.20 DDEC II ELECTRONIC CONTROL MODULE

- 2.21 DDEC I

- 2.22 PROGRAMMABLE READ-ONLY MEMORY (PROM) DDEC I

- 2.23 ELECTRONIC DISTRIBUTOR UNIT DDEC I

- 2.24 ELECTRONIC FOOT PEDAL ASSEMBLY

- 2.25 TURBO BOOST PRESSURE SENSOR

- 2.26 AIR INTAKE PRESSURE SENSOR

- 2.27 OIL PRESSURE SENSOR

- 2.28 OIL TEMPERATURE SENSOR

- 2.29 AIR TEMPERATURE SENSOR

- 2.30 AIR TEMPERATURE SENSOR FOR HIGH PRESSURE FUEL SYSTEM

- 2.31 COOLANT TEMPERATURE SENSOR

- 2.32 SYNCHRONOUS REFERENCE SENSOR

- 2.33 TIMING REFERENCE SENSOR

- 2.34 COOLANT LEVEL SENSOR

- 2.35 FUEL PRESSURE SENSOR

- 2.36 FUEL TEMPERATURE SENSOR

- 2.37 EXHAUST GAS OXYGEN SENSOR FOR SERIES 60G ENGINES

- 2.38 EXHAUST TEMPERATURE SENSOR FOR THE SERIES 60G ENGINES

- 2.39 KNOCK SENSOR AND SIGNAL NOISE ENHANCEMENT FILTER MODULE

- 2.40 BAROMETRIC PRESSURE SENSOR FOR THE SERIES 60G ENGINE WITH HIGH PRESSURE FUEL SYSTEM

- 2.41 OVERVIEW OF HIGH PRESSURE FUEL SYSTEM FOR SERIES 60G ENGINES

- 2.42 FUEL PRESSURE GAGES FOR THE SERIES 60G ENGINE WITH A HIGH PRESSURE FUEL SYSTEM

- 2.43 VENTING AND LEAK CHECKING PROCEDURES FOR A NATURAL GAS ENGINE (HIGH PRESSURE SYSTEM)

- 2.44 HIGH PRESSURE FUEL REGULATOR FOR THE SERIES 60G ENGINE

- 2.45 PULSE WIDTH MODULATED STEPPER MOTOR VALVE (PSV) FOR SERIES 60G AUTOMOTIVE ENGINES

- 2.46 FUEL MIXER FOR THE SERIES 60G HIGH PRESSURE FUEL SYSTEM

- 2.47 FUEL SHUTOFF VALVE FOR SERIES 60G ENGINE WITH HIGH PRESSURE FUEL SYSTEM

- 2.48 IMPCO LOW PRESSURE FUEL REGULATOR FOR THE SERIES 60G ENGINE HIGH PRESSURE FUEL SYSTEM

- 2.49 OVERVIEW OF THE LOW PRESSURE NATURAL GAS FUEL SYSTEM

- 2.50 LOW PRESSURE FUEL REGULATOR FOR THE SERIES 60G ENGINE

- 2.51 FUEL MIXER FOR THE SERIES 60G LOW PRESSURE SYSTEM

- 2.52 VENTING AND LEAK CHECKING PROCEDURES FOR NATURAL GAS ENGINE (LOW PRESSURE SYSTEM)

- 2.A ADDITIONAL INFORMATION

- 3 LUBRICATION SYSTEM

- 3.1 OVERVIEW OF LUBRICATING SYSTEM

- 3.2 OIL PUMP

- 3.3 OIL PRESSURE REGULATOR VALVE

- 3.4 OIL PRESSURE RELIEF VALVE

- 3.5 OIL FILTER

- 3.6 OIL FILTER ADAPTOR

- 3.7 THERMATIC OIL CONTROL VALVE

- 3.8 OIL COOLER (1991 AND LATER ENGINES)

- 3.9 OIL COOLER (PRE-1991 ENGINES)

- 3.10 OIL LEVEL DIPSTICK ASSEMBLY

- 3.11 OIL PAN

- 3.12 VENTILATING SYSTEM

- 3.A ADDITIONAL INFORMATION

- 4 COOLING SYSTEM

- 4.1 COOLING SYSTEM OVERVIEW

- 4.2 WATER PUMP (GEAR CASE MOUNTED - 1991 AND LATER) (GCM)

- 4.3 WATER PUMP (FRONT MOUNTED) (FM)

- 4.4 CHARGE AIR COOLER RAW WATER PUMP (KEEL-COOLED COMMERCIAL MARINE)

- 4.5 THERMOSTAT

- 4.6 COOLANT PRESSURE CONTROL CAP

- 4.7 ENGINE COOLING FAN

- 4.8 COOLANT FILTER AND CONDITIONER

- 4.9 RADIATOR

- 4.10 KEEL COOLING SYSTEM (COMMERCIAL MARINE)

- 4.11 HEAT EXCHANGER COOLING SYSTEM (PLEASURE CRAFT MARINE)

- 4.12 HEAT EXCHANGER (PLEASURE CRAFT MARINE)

- 4.13 JABSCO® ENGINE COOLING RAW WATER PUMP (MARINE)

- 4.A ADDITIONAL INFORMATION

- 5 FUEL, LUBRICATING OIL, AND COOLANT

- 5.1 FUEL

- 5.2 LUBRICATING OIL (DIESEL)

- 5.3 LUBRICATING OIL FOR THE SERIES 60G ENGINE

- 5.4 COOLANT

- 6 AIR INTAKE SYSTEM

- 6.1 AIR INTAKE SYSTEM OVERVIEW

- 6.2 AIR CLEANER

- 6.3 AIR SEPARATOR

- 6.4 INTAKE MANIFOLD

- 6.5 CLOSED CRANKCASE BREATHER FOR SERIES 60G AUTOMOTIVE ENGINES

- 6.6 TURBOCHARGER (DIESEL)

- 6.7 TURBOCHARGER SERIES 60 GAS ENGINES (GENSET)

- 6.8 TURBOCHARGER SERIES 60 NATURAL GAS (AUTOMOTIVE) ENGINE

- 6.9 RECIRCULATION VALVE FOR SERIES 60G AUTOMOTIVE ENGINE

- 6.10 CHARGE AIR COOLER

- 6.11 THROTTLE ACTUATOR FOR THE SERIES 60G ENGINE

- 6.12 AIR DRYER

- 6.A ADDITIONAL INFORMATION

- 7 EXHAUST SYSTEM

- 7.1 OVERVIEW OF EXHAUST SYSTEM

- 7.2 EXHAUST MANIFOLD

- 8 ELECTRICAL EQUIPMENT

- 8.1 OVERVIEW OF ELECTRICAL SYSTEM

- 8.2 BATTERY CHARGING ALTERNATOR

- 8.3 STORAGE BATTERY

- 8.4 CRANKING MOTOR

- 8.5 TACHOMETER DRIVE

- 8.6 DDEC III/IV ENGINE SENSOR HARNESS

- 8.7 DDEC II ENGINE SENSOR HARNESS

- 8.8 METRI-PACK 150 SERIES CONNECTORS

- 8.9 MICRO-PACK SERIES CONNECTORS

- 8.10 WEATHER PACK AND METRI-PACK 280 SERIES CONNECTORS

- 8.11 CONNECTOR TOOLS

- 8.12 SPLICING GUIDELINES

- 8.A ADDITIONAL INFORMATION

- 9 POWER TAKE-OFF

- 9.1 FRONT MOUNTED POWER TAKE-OFF

- 9.2 REAR ENGINE POWER TAKE-OFF (REPTO) ASSEMBLY

- 10 SPECIAL EQUIPMENT

- 10.1 AIR COMPRESSOR (VEHICLE APPLICATIONS ONLY)

- 10.2 AIR COMPRESSOR DRIVE HUB

- 10.3 AIR COMPRESSOR/RAW WATER PUMP DRIVE ASSEMBLY

- 10.4 KIM HOT START STARTING AID SYSTEM (MARINE)

- 10.A ADDITIONAL INFORMATION

- 11 OPERATION AND VERIFICATION

- 11.1 PREPARATION FOR A FIRST TIME START

- 11.2 STARTING

- 11.3 RUNNING

- 11.4 STOPPING

- 11.5 OPERATING CONDITIONS

- 11.6 SERIES 60G GENSET ENGINE OPERATING CONDITIONS

- 11.7 SERIES 60G AUTOMOTIVE ENGINE OPERATING CONDITIONS

- 11.8 ENGINE RUN-IN INSTRUCTIONS

- 12 ENGINE TUNE-UP

- 12.1 ENGINE TUNE-UP PROCEDURES

- 12.2 VALVE LASH, INJECTOR HEIGHT (TIMING) AND JAKE BRAKE® LASH ADJUSTMENTS

- 12.3 ENGINE TUNE-UP PROCEDURES FOR THE SERIES 60G ENGINE

- 12.4 VALVE LASH FOR THE SERIES 60G ENGINE

- 13 PREVENTIVE MAINTENANCE

- 13.1 MAINTENANCE OVERVIEW

- 13.2 DAILY MAINTENANCE - ALL APPLICATIONS

- 13.3 DAILY MAINTENANCE - MARINE APPLICATIONS

- 13.4 MAINTENANCE OF MARINE ENGINES

- 13.5 MAINTENANCE OF VEHICLE ENGINES

- 13.6 MAINTENANCE OF ENGINES USED IN STATIONARY AND INDUSTRIAL APPLICATIONS

- 13.7 MAINTENANCE OF SERIES 60 DIESEL ENGINES FOR GENERATOR SET

- 13.8 MAINTENANCE OF SERIES 60G ENGINES FOR GENERATOR SET

- 13.9 LUBRICATING OIL AND FILTER CHANGE INTERVALS FOR GENSET

- 13.10 PREVENTIVE MAINTENANCE FOR THE SERIES 60G AUTOMOTIVE ENGINE (CITY TRANSIT COACH)

- 13.11 MAINTENANCE OF SERIES 60G AUTOMOTIVE ENGINES

- 13.12 LUBRICATING OIL AND FILTER CHANGE INTERVALS FOR GENSET (WITH HIGH SULFUR FUELS)

- 13.13 DESCRIPTION OF MAINTENANCE ITEMS

- 13.14 AIR SEPARATOR FILTER ELEMENT (MARINE)

- 13.15 DETECTING INTERNAL FUEL LEAKS

- 13.16 CLEANING CONTAMINATED LUBRICATION OIL SYSTEM

- 14 STORAGE

- 14.1 PREPARING ENGINE FOR STORAGE

- 14.2 RESTORING AN EXTENDED STORAGE ENGINE

- 14.3 WINTER STORAGE FOR MARINE ENGINE

- 15 IGNITION SYSTEM

- 15.1 OVERVIEW OF IGNITION SYSTEM

- 15.2 COIL OVER PLUG IGNITION SYSTEM

- 15.3 IGNITION BOOT ASSEMBLY

- 15.4 IGNITER MODULE

- 15.5 IGNITER MODULE BRACKET

- 15.6 IGNITION COIL HARNESS

- 15.7 SPARK PLUGS

- 16 MISFIRING CYLINDER

- 16.1 POOR VEHICLE GROUND

- 16.2 AERATED FUEL

- 16.3 IMPROPER INJECTOR CALIBRATION SETTING (DDEC III/IV ENGINES ONLY)

- 16.4 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR DAMAGED CAMSHAFT LOBES AND ROLLERS

- 16.5 FAULTY FUEL INJECTOR

- 16.6 FAULTY ELECTRONIC CONTROL MODULE

- 16.7 WORN OR DAMAGED VALVE OR CYLINDER KIT

- 17 STARTING DIFFICULTY (ENGINE ROTATES)

- 17.1 ELECTRONIC CONTROL MODULE WIRING HARNESS

- 17.2 EMPTY FUEL TANK

- 17.3 LOW BATTERY VOLTAGE

- 17.4 CORRODED OR DAMAGED BATTERY TERMINALS

- 17.5 DEFECTIVE MAGNETIC SWITCH

- 17.6 DEFECTIVE STARTER

- 17.7 LOW CRANKING SPEED

- 17.8 FUEL SUPPLY VALVE

- 17.9 PLUGGED FUEL FILTER(S)

- 17.10 FUEL PUMP

- 17.11 AERATED FUEL

- 17.12 RESTRICTIVE AIR FILTER

- 17.13 LOW COMPRESSION

- 18 NO START (ENGINE WILL NOT ROTATE)

- 18.1 DISCHARGED BATTERY

- 18.2 DEFECTIVE MAGNETIC SWITCH

- 18.3 DEFECTIVE STARTER

- 18.4 INTERNAL ENGINE DAMAGE

- 19 EXCESSIVE OIL CONSUMPTION

- 19.1 MISCALIBRATED DIPSTICK

- 19.2 EXTERNAL OIL LEAKS

- 19.3 LEAKING OIL COOLER CORE

- 19.4 DEFECTIVE AIR COMPRESSOR

- 19.5 DEFECTIVE TURBOCHARGER

- 19.6 WORN OR DAMAGED VALVE OR CYLINDER KIT

- 20 EXCESSIVE CRANKCASE PRESSURE

- 20.1 OBSTRUCTION OR DAMAGE TO ROCKER COVER BREATHER

- 20.2 DEFECTIVE AIR COMPRESSOR

- 20.3 DEFECTIVE TURBOCHARGER

- 20.4 WORN OR DAMAGED VALVE OR CYLINDER KIT

- 21 EXCESSIVE EXHAUST SMOKE (BLACK OR GRAY)

- 21.1 IMPROPER GRADE OF FUEL OIL

- 21.2 RESTRICTED AIR CLEANER ELEMENT

- 21.3 RESTRICTED OR CRACKED CHARGE AIR COOLER

- 21.4 FAULTY EXHAUST SYSTEM

- 21.5 FAULTY FUEL INJECTOR

- 21.6 DEFECTIVE TURBOCHARGER

- 22 EXCESSIVE BLUE SMOKE

- 22.1 DEFECTIVE TURBOCHARGER

- 22.2 WORN OR DAMAGED VALVE OR CYLINDER KIT

- 23 EXCESSIVE WHITE SMOKE

- 23.1 IMPROPER GRADE OF FUEL

- 23.2 DEFECTIVE FUEL PUMP

- 23.3 AERATED FUEL

- 23.4 IMPROPER INJECTOR CALIBRATION SETTING (DDEC III/IV ENGINES ONLY)

- 23.5 IMPROPER VALVE CLEARANCE OR INJECTOR HEIGHT, WORN OR DAMAGED CAMSHAFT LOBES AND ROLLERS

- 23.6 FAULTY FUEL INJECTOR

- 23.7 FAULTY ELECTRONIC CONTROL MODULE

- 24 ROUGH RUNNING OR STALLING

- 24.1 LOW BATTERY VOLTAGE

- 24.2 AERATED FUEL OIL

- 24.3 INSUFFICIENT FUEL OIL FLOW

- 24.4 HIGH FUEL OIL TEMPERATURE RETURN

- 24.5 IMPROPER INJECTOR CALIBRATION SETTING (DDEC III/IV ENGINES ONLY)

- 24.6 LOW COMPRESSION PRESSURE

- 25 LACK OF POWER

- 25.1 AERATED FUEL

- 25.2 HIGH FUEL PRESSURE

- 25.3 HIGH FUEL OIL TEMPERATURE RETURN

- 25.4 RESTRICTED AIR CLEANER ELEMENT

- 25.5 RESTRICTED OR CRACKED CHARGE AIR COOLER OR LEAKING INTAKE MANIFOLD

- 25.6 FAULTY EXHAUST SYSTEM

- 25.7 HIGH INLET AIR TEMPERATURE

- 25.8 HIGH ALTITUDE OPERATION

- 25.9 INCORRECT CAMSHAFT TIMING

- 26 LOW OIL PRESSURE

- 26.1 IMPROPER ENGINE OIL LEVEL

- 26.2 IMPROPER LUBRICATING OIL VISCOSITY

- 26.3 LUBRICATING OIL DILUTED WITH FUEL OIL OR ENGINE COOLANT

- 26.4 FAULTY OIL PRESSURE GAUGE SENSOR

- 26.5 OIL PRESSURE GAUGE LINE OBSTRUCTED

- 26.6 ROCKER ARM SHAFT PLUGS MISSING (NEW OR REBUILT ENGINES ONLY)

- 26.7 RESTRICTED OIL COOLER

- 26.8 NONFUNCTIONAL OR STICKING OIL PRESSURE REGULATOR VALVE

- 26.9 DEFECTIVE BYPASS VALVE

- 26.10 DEFECTIVE PRESSURE RELIEF VALVE

- 26.11 DEFECTIVE PICKUP SCREEN TUBE AND SCREEN ASSEMBLY

- 26.12 DEFECTIVE CRANKSHAFT MAIN BEARING SHELLS

- 26.13 DEFECTIVE OIL PUMP ASSEMBLY

- 27 HIGH ENGINE COOLANT TEMPERATURE

- 27.1 IMPROPER ENGINE COOLANT LEVEL

- 27.2 INSUFFICIENT RADIATOR AIR CIRCULATION

- 27.3 FAULTY PRESSURE CONTROL CAP

- 27.4 DEFECTIVE COOLANT HOSES

- 27.5 FAN BELTS ARE INCORRECTLY ADJUSTED

- 27.6 INOPERATIVE THERMO-MODULATED FAN

- 27.7 FAULTY THERMOSTATS

- 27.8 FAULTY WATER PUMP

- 27.9 COMBUSTION GASES IN COOLANT

- 27.10 ABNORMAL RADIATOR COOLANT FLOW

- 28 LOW COOLANT TEMPERATURE

- 28.1 FAULTY THERMOSTATS

- 28.2 INSUFFICIENT RADIATOR AIR CIRCULATION

- 29 POOR FUEL ECONOMY

- 29.1 PROBABLE CAUSE

Screenshots for Detroit Diesel Series 60 Diesel / Natural Gas-Fueled / Diesel Marine Engines Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Detroit Diesel Series 60 Diesel / Natural Gas-Fueled / Diesel Marine Engines Service Manual PDF:

Detroit Diesel Diagnostic Link 8.23 SP2 (replaces DDDL 8.13, 8.14) Offline Professional

Detroit Diesel DiagnosticLink 8.23 SP2 Professional Offline 01/2026 ALL Grayed Parameters Enabled. Hardware Level 10. Download & Remote Support

200$

[01/2026]

|

Detroit Diesel Reprograming System 7.11

Program Detroit Diesel Reprograming System 7.11 is designed to perform all diagnostic operations for systems programming lineup in 2007 and 2011.

250$

[07/2013]

|

Detroit Diesel Diagnostic Link 7.11 (DDDL 7.11 / 6.50)

Program for diagnostic Detroit Diesel Diagnostic Link 7.11 (DDDL 7.11 / 6.50) intended for serve and diagnose Detroit Diesel

100$

[12/2013]

|

Detroit Diesel Reprogramming Software 7.09 (DDRS 7.09)

Detroit Diesel Reprogramming Software 7.09 (DDRS 7.09) is the electronic tool for servicing Detroit Diesel

150$

[09/2012]

|