![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

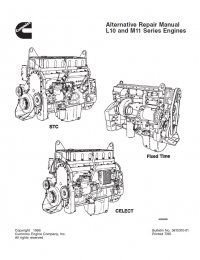

This alternative repair manual contains specifications and instructions for repairing damaged or worn components. This manual has a convenient interface and supports English. The repair manual is a system of care in servicing and repairing diesel engines of the L10 and M11 series, which allows the identification and resolution of problems and inaccuracies. The repair manual comes in PDF format and includes 355 pages, all of which are printable. To view the information, you need to install Adobe Reader (or an equivalent application).

Contents

- Introduction

- Group 00 - General Repairs

- Group 01 - Cylinder Block and Crankshaft

- Group 02 - Cylinder Head

- Additional Service Literature

- Component Manufacturers

- Index

The Groups 00, 01, and 02 contents are detailed described below:

Section 00 - General Repairs

Section 01 — Cylinder Block

Cam Follower Stud Thread Repair

- Cam Follower Stud Thread Repair (Page 1-47)

- General Information (Page 1-47)

- Repair Procedure (Page 1-47)

- Specifications — Cam Follower Stud Repair (Page 1-53)

Camshaft Bore Repair

- General Information (Page 1-13)

- Initial Preparation and Inspection (Page 1-13)

- Camshaft Bore Repair (Pages start 1-13)

- Camshaft Bore Cutting Tool — Installation (Page 1-16)

- Camshaft Bore Cutting Tool — Setting Cutter (Page 1-19)

- Camshaft Bores — Machining (Page 1-21)

- Camshaft Bushing and Salvage Sleeve - Assembly (Page 1-15)

- Camshaft Bushing Assembly and Salvage Sleeve — Installation (Page 1-25)

- Specifications — Camshaft Bore Repair (Page 1-27)

Crankshaft Inspection and Reconditioning

- Crankshaft — Exploded View (Page 1-142)

- General Information (Page 1-143)

- Equipment (Page 1-143)

- Crankshaft Inspection and Reconditioning (Page 1-143 and following)

- Crankshaft Inspection (Page 1-151)

- Crankshaft Circumferential Defects (Coil Shot) — Inspection (Page 1-175)

- Crankshaft Longitudinal Defects (Head Shot) - Inspection (Page 1-173)

- Crankshaft Magnetic Crack Inspection — Continuous Method (Page 1-165)

- Magnetic Inspection — Limits of Acceptability (Page 1-166)

- Crankshaft De-Magnetization (Page 1-176)

- Grinding Machine and Wheels (Page 1-177)

- Crankshaft — Cleaning (Page 1-177)

- Grinding the Connecting Rod Bearing Journals (Page 1-192)

- Grinding the Main Bearing Journals (Page 1-199)

- Crankshaft Reconditioning Process (Page 1-186)

- Crankshaft Thrust Bearing Surface Repair (Page 1-206)

- Crankshaft Thread — Repair (Page 1-207)

- Processing After Grinding (Page 1-208)

- Specifications — Crankshaft Repair (Page 1-224)

Cylinder Block Crankshaft Thrust Surface Machining

- General Information (Page 1-126)

- Initial Preparation and Inspection (Page 1-126)

- Cylinder Block Crankshaft Thrust Surface Machining (Page 1-126 and following)

- Crankshaft Thrust Face — Machining (Page 1-133)

- Crankshaft Thrust Surface Cutting Tool - Installation (Page 1-128)

- Crankshaft Thrust Surface Cutting Tool - Setting Cutter (Page 1-130)

- Final Inspection (Page 1-135)

- Specifications — Cylinder Block Crankshaft Thrust Surface Machining (Page 1-137)

Cylinder Block Idler Shaft Ring Dowel Bore Repair

- General Information (Page 1-67)

- Repair Procedure (Page 1-67)

Cylinder Block — Exploded View

Page 1-6

Cylinder Block Resurfacing

- General Information (Page 1-7)

- Initial Preparation and Inspection (Page 1-7)

- Specification — Cylinder Block Resurfacing (Page 1-12)

Cylinder Head Capscrew Thread Repair

- General Information (Page 1-40)

- Repair Procedure (Page 1-40)

- Specifications — Cylinder Head Capscrew Thread Repair (Page 1-46)

Cylinder Liner Counterbore Machining (Electric Cutting Tool)

- General Information (Page 1-85)

- Repair Procedure (Page 1-86)

- Specifications — Cylinder Liner Counterbore Machining (Page 1-95)

Cylinder Liner Counterbore Machining (Manual Cutting Tool)

- General Information (Page 1-73)

- Repair Procedure (Page 1-74)

- Specifications — Cylinder Liner Counterbore Machining (Page 1-84)

Flywheel Housing Mounting Capscrew Thread Repair

- General Information (Page 1-62)

- Repair Procedure (Page 1-62)

- Specifications — Flywheel Housing Mounting Capscrew Thread Repair (Page 1-63)

Gear Plate and Gear Cover Mounting Capscrew Thread Repair

- General Information (Page 1-58)

- Repair Procedure (Page 1-59)

- Specifications — Gear Plate and Gear Cover Mounting Capscrew Thread Repair (Page 1-61)

Idler Gear Bushing Repair

- General Information (Page 1-138)

- Repair Procedure (Page 1-139)

- Specifications — Idler Gear Bushing Repair (Page 1-140)

Idler Gear Capscrew Thread Repair

- General Information (Page 1-54)

- Repair Procedure (Page 1-55)

- Specification — Idler Gear Capscrew Thread Repair (Page 1-57)

Lubricating Oil Pump Mounting Capscrew Thread Repair

- General Information (Page 1-64)

- Repair Procedure (Page 1-64)

- Specifications — Flywheel Housing Mounting Capscrew Thread Repair (Referenced at Page 1-63, may apply similarly)

Main Bearing Bore Repair

- General Information (Page 1-96)

- Initial Preparation and Inspection (Page 1-96)

- Main Bearing Bore Alignment — Inspection (Page 1-98)

- Main Bearing Bore Tool — Installation (Page 1-102)

- Main Bearing Bore Cutting Tool — Setting Cutter (Page 1-105)

- Main Bearing Bore — Machining (Page 1-108)

- Main Bearing Bore Repair Sleeve — Installation (Page 1-112)

- Main Bearing Cap — Installation (Page 1-118)

- Main Bearing Bore Dowel Holes — Redrilling (Page 1-119)

- Repair Sleeve and Replacement Cap - Machining (Page 1-121)

- Final Inspection (Page 1-123)

- Specifications — Main Bearing Bore Repair (Page 1-125)

Main Bearing Capscrew Thread Repair

- General Information (Page 1-31)

- Repair Procedure (Page 1-32)

- Specifications — Main Bearing Capscrew Thread Repair (Page 1-39)

Piston Cooling Nozzle Thread Repair

- General Information (Page 1-28)

Service Tools — Cylinder Block

Page 1-3

Viscosity Sensor

- General Information (Page 1-29)

- Initial Preparation (Page 1-30)

- Viscosity Sensor Installation (Page 1-31)

Section 02 — Cylinder Head — Group 02

Cylinder Head Resurfacing

- General Information (Page 2-5)

- Initial Preparation and Inspection (Page 2-5)

- Cylinder Head Resurfacing (Page 2-5)

- Cylinder Head Combustion Face — Machining (Page 2-6)

- Final Inspection (Page 2-8)

- Specifications — Cylinder Head Resurfacing (Page 2-11)

Exhaust Manifold Mounting Surface Refacing

- General Information (Page 2-37)

- Initial Inspection (Page 2-37)

- Exhaust Manifold Mounting Surface Refacing (Page 2-37)

- Exhaust Manifold Mounting Surface - Machining (Page 2-38)

- Final Inspection (Page 2-39)

- Specifications — Exhaust Manifold Mounting Surface (Page 2-40)

Exhaust Manifold Capscrew Threaded Hole Repair

- General Information (Page 2-41)

- Repair Procedure (Page 2-41)

Exhaust Manifold Repair

- General Information (Page 2-42)

- Initial Preparation and Inspection (Page 2-43)

- Repair Procedure (Page 2-44)

- Center Section Mounting Surfaces - Machining (Page 2-45)

Injector Hold Down Capscrew Threaded Hole Repair

- General Information (Page 2-47)

Injector Sleeve — Replacement

- General Information (Page 2-32)

- Injector Sleeves — Removal (Page 2-32)

- Initial Inspection (Page 2-33)

- Injector Sleeve Bead Seat — Repair (Page 2-33)

- Injector Sleeves — Installation (Page 2-34)

Oversize Valve Guides — Installation

- General Information (Page 2-12)

- Initial Preparation and Inspection (Page 2-12)

- Valve Guide Bore — Machining (Page 2-12)

- Oversize Valve Guide — Installation (Page 2-13)

- Specifications — Oversize Valve Guide (Page 2-15)

Oversize Valve Seat Inserts — Installation

- General Information (Page 2-16)

- Initial Inspection (Page 2-16)

- Valve Seat Insert Bore — Machining (Page 2-17)

- Oversize Valve Seat Insert — Installation (Page 2-23)

- Specifications — Oversize Valve Seat Inserts (Page 2-25)

Service Tools — Cylinder Head

Page 2-2

Valve Seats — Grinding

- General Information (Page 2-26)

- Initial Inspection (Page 2-26)

- Grinder Wheel — Dressing (Page 2-27)

- Valve Seat Insert — Grinding (Page 2-28)

- Final Inspection (Page 2-30)

- Specifications — Valve Seat Insert (Page 2-31)