![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Case CX20B CX22B CX27B Hydraulc Excavator Shop Manual PDF

[12/2004]Electronic shop manual provides detailed service information, repair information, operating instructions and maintenance manuals, service manuals, instructions for use and installation, designed to serve the hydraulic excavator Case.

Service repair manual contains information on such models of hydraulic tractors:

CX20B,

CX22B,

CX27B.

Shop manual contains a description of all repair and service procedures, step by step instructions for operation and maintenance, troubleshooting instructions.

Online manual required each owner of equipment Case, which is equipped with electronic equipment.

This manual is help system operation and maintenance of excavators Case, which allows to detect and eliminate problems encountered and inaccuracies.

This shop manual has a friendly and easy to use interface that supports English. Manual comes in PDF format, includes 766 pages. All pages are printable.

Contents of this manual:

- 1. OUTLINE

- 1.1 GENERAL PRECAUTIONS FOR REPAIRS

- 1.1.1 PREPARATION BEFORE DISASSEMBLING

- 1.1.2 SAFETY IN DISASSEMBLING AND ASSEMBLING

- 1.1.3 DISASSEMBLING AND ASSEMBLING HYDRAULIC EQUIPMENT

- 1.1.4 ELECTRICAL EQUIPMENT

- 1.1.5 HYDRAULIC PARTS

- 1.1.6 WELDING REPAIR

- 1.1.7 ENVIRONMENTAL MEASURE

- 1.2 INTERNATIONAL UNIT CONVERSION SYSTEM

- 2. SPECIFICATIONS

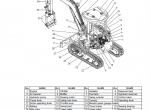

- 2.1 COMPONENTS NAME

- 2.2 MACHINE DIMENSIONS

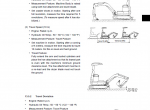

- 2.3 SPECIFICATIONS AND PERFORMANCE

- 2.4 MACHINE & COMPONENTS WEIGHT (DRY)

- 2.5 TRANSPORTATION

- 2.6 TYPE OF CRAWLER SHOES

- 2.7 TYPE OF BUCKET

- 2.8 ENGINE SPECIFICATIONS

- 2.8.1 SPECIFICATIONS

- 2.8.2 ENGINE PERFORMANCE CURVE

- 3. ATTACHMENT DIMENSIONS

- 3.1 BOOM

- 3.1.1 BOOM DIMENSIONAL DRAWINGS

- 3.1.2 BOOM MAINTENANCE STANDARDS

- 3.2 ARM

- 3.2.1 ARM DIMENSIONAL DRAWINGS

- 3.2.2 ARM MAINTENANCE STANDARDS

- 3.3 BUCKET

- 3.3.1 BUCKET DIMENSIONAL DRAWINGS

- 3.3.2 DETAIL DIMENSIONAL DRAWINGS OF LUG SECTION

- 3.4 DOZER

- 3.4.1 DOZER DIMENSIONAL DRAWINGS

- 3.4.2 DOZER MAINTENANCE STANDARDS

- 3.5 SWING

- 3.5.1 SWING BRACKET DIMENSIONAL DRAWINGS

- 3.5.2 SWING PORTION MAINTENANCE STANDARDS

- 11. TOOLS

- 11.1 TORQUE SPECIFICATIONS FOR CAPSCREWS & NUTS

- 11.1.1 METRIC COARSE THREAD STANDARD TIGHTENING TORQUE

- VALUES. MAKE CERTAIN TO TIGHTEN ALL CAPSCREWS & NUTS

- TO PROPER TORQUE VALUES

- 11.1.2 METRIC FINE THREAD STANDARD TIGHTENING TORQUE VALUES.

- MAKE CERTAIN TO TIGHTEN ALL CAPSCREWS & NUTS TO PROPER

- TORQUE VALUES

- 11.2 SCREW AND TOOL SIZES

- 11.2.1 CAPSCREW

- 11.2.2 CAPSCREW (SOCKET BOLT)

- 11.3 TORQUE SPECIFICATIONS FOR JOINTS AND HOSES

- 11.3.1 JOINTS FOR PIPING (O-RING SEALING TYPE)

- 11.3.2 HYDRAULIC HOSE (30° FLARE TYPE)

- 11.4 TORQUE SPECIFICATIONS FOR SLEEVE TYPE TUBE FITTINGS

- 11.4.1 SLEEVE TYPE TUBE FITTINGS

- 11.5 SPECIAL SPANNERS FOR TUBES

- 11.6 APPLICATION OF SCREW LOCKING AND SEALING COMPOUNDS

- 11.7 COUNTERWEIGHT LIFTING JIG

- 12. STANDARD MAINTENANCE

- 12.1 STANDARD WORKING TIME TABLE FOR THE MAINTENANCE OF EXCAVATOR

- 13. MAINTENANCE STANDARDS AND

- 13.1 HOW TO USE MAINTENANCE STANDARDS AND PRECAUTIONS

- 13.2 PERFORMANCE INSPECTION STANDARD TABLE

- 13.2.1 STANDARD VALUE TABLE

- 13.3 MEASURING ENGINE SPEED

- 13.3.1 ENGINE SPEED MEASUREMENT

- 13.4 MEASURING HYDRAULIC OIL PRESSURE

- 13.4.1 STANDARD FOR HYDRAULIC OIL PRESSURE MEASUREMENT

- 13.4.2 PRESSURE MEASUREMENT AND ADJUSTMENT

- 13.5 MEASURING TRAVEL PERFORMANCES

- 13.5.1 TRAVEL

- 13.5.2 TRAVEL DEVIATION

- 13.5.3 MOVEMENT DRIFT DUE TO GRAVITY

- 13.5.4 DRAIN RATE ON TRAVEL MOTOR

- 13.6 MEASURING SLEW PERFORMANCES

- 13.6.1 SLEW TIME

- 13.6.2 OVERRUN WHEN SLEWING STOPS

- 13.6.3 SLEW DRIFT DUE TO GRAVITY

- 13.6.4 DRAIN RATE OF TRAVEL MOTOR

- 13.7 MEASURING ATTACHMENT OPERATING PERFORMANCES

- 13.7.1 CYLINDER SPEED

- 13.7.2 GRAVITY DRIFT OF CYLINDERS

- 13.8 MEASURING SLEW BEARING PERFORMANCES

- 13.8.1 SLEW BEARING-BUCKET TIP PLAY

- 13.8.2 SLEW BEARING PLAY

- 13.9 MEASURING CRAWLER TENSION

- 13.9.1 CRAWLER TENSION

- 22. HYDRAULIC SYSTEM

- 22.1 SUMMARY

- 22.1.1 FUNCTION AND FEATURES OF HYDRAULIC CIRCUIT

- 22.2 HYDRAULIC CIRCUITS AND COMPONENT MODELS

- 22.3 HYDRAULIC CIRCUIT OPERATION

- 22.3.1 COLOR CODING STANDARD FOR HYDRAULIC

- 22.3.2 NEUTRAL CIRCUIT

- 22.3.3 TRAVEL OPERATING CIRCUIT

- 22.3.4 SLEW OPERATING CIRCUIT

- 22.3.5 BUCKET OPERATING CIRCUIT

- 22.3.6 BOOM OPERATING CIRCUIT

- 22.3.7 ARM OPERATING CIRCUIT

- 22.3.8 SWING OPERATING CIRCUIT

- 22.3.9 DOZER OPERATING CIRCUIT

- 22.3.10TRAVEL / DOZER COMBINED OPERATING CIRCUIT

- 22.3.11TRAVEL / BOOM COMBINED OPERATING CIRCUIT

- 22.3.12NIBBLER & BREAKER OPERATING CIRCUIT

- 22.4 SCHEMATIC PIPING FOR HYDRAULIC SYSTEM

- 23. ELECTRICAL SYSTEM

- 23.1 HOW TO READ CIRCUIT DIAGRAM AND HARNESS CONNECTION

- 23.1.1 ELECTRIC CIRCUIT DIAGRAM

- 23.1.2 HARNESS CONNECTION

- 23.2 ELECTRICAL EQUIPMENT & HARNESS

- 23.2.1 ELECTRICAL EQUIPMENT LIST

- 23.2.2 HARNESS & CABLE LIST

- 23.2.3 ARRANGEMENT DRAWING FOR COMPONENTS & HARNESS

- 24. COMPONENTS SYSTEM

- 24.1 HYDRAULIC COMPONENTS

- 24.1.1 HYDRAULIC PUMP

- 24.1.2 PILOT VALVE (ATT)

- 24.1.3 PILOT VALVE (TRAVEL)

- 24.1.4 CONTROL VALVE

- 24.1.5 SLEWING MOTOR

- 24.1.6 TRAVEL MOTOR

- 24.1.7 SWIVEL JOINT

- 24.1.8 CYLINDER

- 24.2 ELECTRICAL EQUIPMENT

- 24.2.1 ELECTRICAL EQUIPMENT LIST

- 24.2.2 SPECIFICATIONS ELECTRICAL EQUIPMENT

- 31. GENERAL DISASSEMBLY AND ASSEMBLY

- 31.1 GENERAL DISASSEMBLY AND ASSEMBLY

- 31.1.1 CONTENTS OF GENERAL DISASSEMBLY AND ASSEMBLY

- 31.1.2 SPECIFICATION OF TIGHTENING TORQUE

- 32. ATTACHMENTS

- 32.1 REMOVING AND INSTALLING

- 32.1.1 ATTACHMENT ASSEMBLY AND NAME

- 32.1.2 BUCKET

- 32.1.3 ARM

- 32.1.4 BOOM

- 32.1.5 SWING

- 32.1.6 DOZER

- 32.2 DISASSEMBLING AND ASSEMBLING

- 32.2.1 CYLINDER

- 33. UPPER SLEWING STRUCTURE

- 33.1 REMOVING AND INSTALLING

- 33.1.1 CANOPY / CAB

- 33.1.2 GUARD (COVER)

- 33.1.3 FLOOR PLATE ASSEMBLY

- 33.1.4 BATTERY

- 33.1.5 COUNTERWEIGHT

- 33.1.6 PUMP

- 33.1.7 CONTROL VALVE

- 33.1.8 SOLENOID VALVE

- 33.1.9 FUEL TANK

- 33.1.10 HYDRAULIC OIL TANK

- 33.1.11 AIR CLEANER

- 33.1.12 GENERATOR

- 33.1.13 MUFFLER

- 33.1.14 CONTROL STAND

- 33.1.15 STARTER

- 33.1.16 RADIATOR

- 33.1.17 ENGINE

- 33.1.18 PILOT VALVE

- 33.1.19 SLEWING MOTOR

- 33.1.20 SWIVEL JOINT

- 33.1.21 UPPER FRAME

- 33.2 DISASSEMBLING AND ASSEMBLING

- 33.2.1 HYDRAULIC PUMP

- 33.2.2 CONTROL VALVE

- 33.2.3 PILOT VALVE (ATTACHMENT)

- 33.2.4 PILOT VALVE (TRAVEL)

- 33.2.5 SLEWING MOTOR

- 33.2.6 SWIVEL JOINT

- 34. TRAVEL SYSTEM

- 34.1 REMOVING AND INSTALLING

- 34.1.1 NAME OF TRAVEL SYSTEM PARTS

- 34.1.2 CRAWLER

- 34.1.3 SLIDE PLATE AND UPPER ROLLER

- 34.1.4 LOWER ROLLER

- 34.1.5 FRONT IDLER

- 34.1.6 IDLER ADJUSTER

- 34.1.7 SPROCKET

- 34.1.8 TRAVEL MOTOR

- 34.1.9 SLEWING BEARING

- 34.2 DISASSEMBLING AND ASSEMBLING

- 34.2.1 TRAVEL MOTOR

- 42. TROUBLESHOOTING - HYDRAULIC SYSTEM

- 42.1 GENERAL PRECAUTIONS

- 42.1.1 CONFIRM ACTUAL TROUBLED CONDITIONS AT SITE

- 42.2 TROUBLE DIAGNOSIS: HYDRAULIC

- 42.3 TROUBLESHOOTING

- 42.3.1 ATTACHMENT

- 42.3.2 TRAVEL OPERATION

- 42.3.3 SLEWING OPERATION

- 42.3.4 PUMP

- 43. TROUBLESHOOTING - ELECTRICAL SYSTEM

- 43.1 TROUBLE DIAGNOSIS: ELECTRIC SYSTEM

- 43.2 TROUBLESHOOTING

- 43.2.1 GENERAL

- 43.2.2 ATTACHMENT OPERATION

- 43.2.3 TRAVEL OPERATION

- 43.2.4 DECELERATION

- 44. TROUBLESHOOTING- ENGINE

- 44.1 TROUBLE DIAGNOSIS: ENGINE

- 44.2 TROUBLESHOOTING

- 44.2.1 STARTING TROUBLE

- 44.2.2 E/G ROTATION TROUBLE

- 44.2.3 OUTPUT DROPS DOWN

- 44.2.4 OTHER TROUBLE

- 44.3 ELECTRICAL EQUIPMENT

- 44.3.1 ELECTRICAL EQUIPMENT LIST

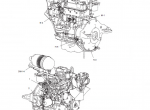

- 51. ENGINE

- 51.1 GENERAL

- 51.2 INSPECTION AND ADJUSTMENT

- 51.3 TROUBLESHOOTING

- 51.4 DISASSEMBLY, INSPECTION AND REASSEMBLY OF ENGINES

- 51.5 LUBRICATION SYSTEM

- 51.6 COOLING SYSTEM

- 51.7 FUEL INJECTION PUMP/GOVERNOR

- 51.8 TURBOCHAGER: DISASSEMBLY, INSPECTION AND REASSEMBLY

- 51.9 STARTING MOTOR

- 51.10ALTERNATOR

- 51.11ELECTRIC WIRING

- 51.12SERVICE STANDARDS

- 51.13TIGHTENING TORQUE FOR BOLTS AND NUTS

- 71. SUPPORTING DATA

- 71.1 HYDRAULIC CIRCUIT DIAGRAM

- 71.1.1 STANDARD SPECIFICATION

- 71.1.2 HYDRAULIC CIRCUIT OPERATION

- 71.1.3 SCHEMATIC PIPING FOR HYDRAULIC SYSTEM

- 71.2 ELECTRIC CIRCUIT DIAGRAM

Screenshots for Case CX20B CX22B CX27B Hydraulc Excavator Shop Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Case CX20B CX22B CX27B Hydraulc Excavator Shop Manual PDF:

eTimGo AGCE for CNH EST 2025 all brands OFFLINE

eTimGo AGCE for CNH EST 05/2025 all brands OFFLINE. Manuals, electrical bulletin diagrams, and diagnostic procedures are provided, including some spare parts catalogs.

1200$

[05/2025]

|

New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software![Diagnostic Software New Holland Electronic Service Tool CNH EST 9.13 [2026] Engineering Diagnostic Software](https://www.epcatalogs.com/file/base/7wA2eiQzaw96Mud+nQLe62FMZmZxTTk819fwjKwFzn9gZlueS7pErMi5cA5I4B9rnJjvyM2KHVeYq8dAqLFqg6eVylUigwGA14M6GWQO8C:2FaqSq5rLX38HGZjM8wALuylflj8yTHY6HQGzotXlCesqQ=/case-new-holland-electronic-service-tools-cnh-est-software-download.png)

The dealer software Electronic Service Tools CNH EST 9.13 update 3 (ex v9.3, v9.4, v9.5, 9.6, 9.7) with the highest engineering access Level available for download or shipping worldwide with online support!

250$

[01/2026]

|

Original CNH DPA5 Diagnostic Service Tool Adapter Cable Kit + CNH EST 9.12

The Case, New Holland (CNH) DPA5 adapter kit includes all the cables. This is a genuine CNH DPA5 kit. Include CNH 9.12 Engineering Software 2025

1699$

[2025]

|

CNH Display Codes for the Paid Features 2023 v1.1

The app generates codes for CNH displays to unlock paid features. Codes are entered through the display

3999$

[2024]

|