![spare parts catalog Clark ForkLift Trucks PartsPro Plus v568 [2026] Parts Catalog](/imgs/type_zapch.gif)

Bobcat 600, 600D, 610, 611 Skid Steer Loaders Service Manual PDF

[06/1987]This service manual is intended for serve and repair Bobcat Skid Steer Loaders 600, 600D, 610, 611.

This manual provides instruction for proper routine servicing and adjustment of the Bobcat, and detailed overhaul instructions of the power train, loader hydraulic/hydrostatic system and general mainframe components.

Service manual is designed to work on a personal computer with Windows & Mac. This manual is a file PDF, which contains 214 pages, any one of which we can be printed easily. We recommend to use Adobe PDF Reader, to be sure all images / graphics will display correctly.

CONTENTS:

- GENERAL SERVICE

- CHANGING AND ADDING HYDRAULIC OIL

- CRANKCASE AIR VENT (DEUTZ)

- CRANKCASE AIR VENT (WISCONSIN)

- DISTRIBUTOR MAINTENANCE (WISCONSIN)

- ENGINE AIR CLEANER

- ENGINE COOLING SYSTEM

- ENGINE OIL

- ENGINE OIL FILTER (DEUTZ)

- ENGINE OIL FILTER (WISCONSIN)

- FUEL ADJUSTMENT (PETTER)

- FUEL FILTERS

- FUEL SPECIFICATIONS

- HEAVY DUTY AIR CLEANER

- HYDRAULIC FLUID FILTER CHANGE

- IGNITION TIMING (WISCONSIN ENGINE)

- LOADER LUBRICATION

- OIL FILTER (PETTER)

- OIL SPECIFICATIONS FOR ENGINES

- OIL TYPE AIR CLEANER

- REMOVING WATER FROM HYDRAULIC TANKS

- SPARK PLUG (WISCONSIN)

- TIRES

- WATER SCRUBBER MUFFLER (600 DIESEL)

- TROUBLESHOOTING

- TROUBLESHOOTING THE DRIVE SYSTEM

- TROUBLESHOOTING THE ENGINE

- TROUBLESHOOTING THE HYDRAULIC SYSTEM

- DRIVE SYSTEM

- ASSEMBLY OF BRAKE

- ASSEMBLY OF DRIVEN SHEAVE (STRAIGHT JACKSHAFT)

- ASSEMBLY OF DRIVEN SHEAVE (TAPERED JACKSHAFT)

- ASSEMBLY OF 610 VARIABLE SPEED W/ROTO–SWIVEL INSIDE

- AXLE BEARING AND SEAL INSTALLATION

- AXLE REMOVAL (FRONT AXLE)

- AXLE SPROCKET REMOVAL INSTALLATION

- BRAKE ADJUSTMENT

- BRAKE DISASSEMBLY

- CLUTCH ADJUSTMENT

- DISASSEMBLY AND ASSEMBLY (CLUTCH)

- DISASSEMBLY OF DRIVEN SHEAVE (STRAIGHT JACKSHAFT)

- DRIVE BELT INSTALLATION (SPLIT SHAFT)

- DRIVE CHAIN ADJUSTMENT

- DRIVEN SHEAVE ALIGNMENT

- DRIVEN SHEAVE DISASSEMBLY

- INSTALLATION OF AXLE

- INSTALLATION OF DRIVEN SHEAVE

- INSTALLING CLUTCH NEEDLE BEARINGS

- JACKSHAFT BEARING INSTALLATION

- LOWER JACKSHAFT INSTALLATION

- LOWER JACKSHAFT REMOVAL

- LOWER JACKSHAFT SPROCKET REPAIR

- REMOVAL OF DRIVEN SHEAVE

- REMOVAL OF FRAME SUPPORT VARIABLE SPEED

- REMOVAL OF VARIABLE DRIVEN SHEAVE WITH ROTO–SWIVEL INSIDE

- REMOVAL OF VARIABLE SHEAVE WITH ROTO–SWIVEL OUTSIDE

- ROTO–SWIVEL ASSEMBLY

- ROTO–SWIVEL DISASSEMBLY

- HYDRAULIC SYSTEM

- ASSEMBLY OF HYDRAULIC PUMP (WEBSTER PUMPS)

- ASSEMBLY OF VARIABLE SPEED CONTROL VALVE SEAL REPLACEMENT WITH CONTROL VALVE

- CARTRIDGE RELEASE ADJUSTMENT

- CHECKING CONDITION OF HYDRAULIC PUMP

- CHECKING PRESSURE ADJUSTMENT

- CHECKING THE CONDITION OF HYDRAULIC SYSTEM

- CHECKING THE PRESSURE SETTING OF THE CARTRIDGE RELEASE

- CHECKING VARIABLE SPEED VALVE PRESSURE ADJUSTMENT

- CONTROL VALVE SEAL INSTALLATION

- DISASSEMBLY

- DISASSEMBLY OF VARIABLE SPEED CONTROL VALVE

- HYDRAULIC CIRCUIT OPERATION

- HYDRAULIC CYLINDER ASSEMBLY

- HYDRAULIC LIFT OR TILT CYLINDER DISASSEMBLY

- HYDRAULIC PUMP ALIGNMENT (500 ELECTRIC)

- HYDRAULIC PUMP ALIGNMENT (600 WISCONSIN)

- HYDRAULIC PUMP ASSEMBLY (CESSNA PUMP)

- HYDRAULIC PUMP DISASSEMBLY (CESSNA PUMP)

- HYDRAULIC PUMP SERVICE (WEBSTER PUMP)

- HYDRAULIC SYSTEM (600 ELECTRIC & 600 DIESEL W/PETTER ENGINE)

- HYDRAULIC SYSTEM (600 & 610 DIESEL W/DEUTZ ENGINE

- HYDRAULIC SYSTEM (600, 610 GASOLINE & LP GAS)

- INSTALLATION OF CYLINDER SEALS

- INSTALLING VALVE SPOOL SEALS IN THE VARIABLE SPEED CONTROL VALVE

- WISCONSIN ENGINE SERVICE

- ASSEMBLY OF VAPORIZER

- ASSEMBLY FUEL BOWL AND INTAKE ASSEMBLY

- ASSEMBLY THROTTLE BODY

- ASSEMBLE VAPORIZER

- ASSEMBLY OF ENGINE AFTER RECONDITIONING INSTALLATION OF VALVE TAPPETS

- ASSEMBLY OF FUEL BOWL AND THROTTLE BODY

- CARBURETOR ADJUSTMENT

- CARBURETOR RECONDITIONING

- DISASSEMBLE THROTTLE BODY

- DISASSEMBLING VAPORIZER

- DISASSEMBLY OF THE FUEL BOWL

- ENGINE RECONDITIONING

- FUEL FILTER LOCK–OFF DISASSEMBLY

- GOVERNOR ADJUSTMENT

- INSTALLATION OF ACCESSORIES

- INSTALLATION OF AIR HOUSING

- INSTALLATION OF CAMSHAFT

- INSTALLATION OF CAMSHAFT GEAR

- INSTALLATION OF CARBURETOR & MANIFOLD ASSEMBLY

- INSTALLATION OF CRANKSHAFT

- INSTALLATION OF CYLINDER BLOCKS

- INSTALLATION OF CYLINDER HEAD

- INSTALLATION OF FLYWHEEL

- INSTALLATION OF GEAR COVER

- INSTALLATION OF IDLER GEAR & SHAFT

- INSTALLATION OF OIL PUMP

- INSTALLATION OF PISTON RINGS

- INSTALLATION OF PISTONS & CONNECTING RODS

- INSTALLATION OF VALVES & SEAT INSERTS

- LP CARBURETOR ASSEMBLING

- LP CARBURETOR CLEANING AND INSPECTION

- LP CARBURETOR DISASSEMBLY PROCEDURE

- LP CARBURETOR RECONDITIONING

- LP CARBURETOR REMOVAL

- LP CARBURETOR SERVICE

- LP FUEL FILTER LOCK–OFF

- OIL PAN INSTALLATION

- REMOVAL OF ACCESSORIES

- REMOVAL OF AIR HOUSING

- REMOVAL OF CAMSHAFT

- REMOVAL OF CARBURETOR & MANIFOLD

- REMOVAL OF CRANKSHAFT

- REMOVAL OF CYLINDER BLOCKS

- REMOVAL OF CYLINDER HEAD

- REMOVAL OF ENGINE

- REMOVAL OF FLYWHEEL

- REMOVAL OF GEAR COVER

- REMOVAL OF IDLER GEAR & SHAFT

- REMOVAL OF OIL PAN

- REMOVAL OF OIL PUMP

- REMOVAL OF PISTONS & CONNECTING RODS

- REMOVAL OF VALVE TAPPETS

- REMOVAL OF VALVES & SEAT INSERTS

- RETURN OF NORMAL COMPRESSION

- RETURN STORED ENGINE TO SERVICE

- STORAGE OF ENGINE

- VAPORIZER & PRIMARY REGULATOR SERVICE

- DEUTZ ENGINE SERVICE

- ASSEMBLE THE ENGINE

- CHECKS AND ADJUSTMENTS

- COMPRESSION CHECKS

- CONNECTING ROD BEARING CHECK AND REPLACEMENT

- COOLING AIR BLOWER

- CRANKCASE CHECK

- CRANKSHAFT AND BEARING CHECKS AND INSTALLATION

- CRANKSHAFT CHECK

- CRANKSHAFT RECONDITIONING

- CYLINDER CHECK

- CYLINDER HEAD REPAIR

- ENGINE RECONDITIONING

- FRONT COVER CHECK AND REPAIR OF ENGINE GOVERNOR

- FUEL INJECTION NOZZLE REMOVAL AND INSTALLATION

- FUEL INJECTION PUMP CHECK

- FUEL SYSTEM CHECK

- GENERAL ENGINE DATA

- GOVERNOR CHECK AND REPAIR

- MAIN BEARING CHECK AND INSTALLATION

- NEW GEAR STARTER RING ON FLYWHEEL INSTALLATION

- OIL PUMP CHECKING

- PISTON CHECK AND MEASURING

- PISTON PIN BUSHING CHECK AND REPLACEMENT

- ROCKER ARM REPAIR

- START OF FUEL INJECTION ADJUSTMENT

- T.D.C. AND START OF FUEL INJECTION

- TIGHTENING BOLTS AND STUDS

- VALVE CLEARANCE ADJUSTMENT

- PETTER ENGINE SERVICE

- CAMSHAFT INSTALLATION

- CAMSHAFT REMOVAL

- CONNECTING ROD ASSEMBLY

- CONNECTING ROD REMOVAL

- CRANKSHAFT REMOVAL

- CYLINDER AND PISTON INSTALLATION

- CYLINDER HEAD INSTALLATION

- DECOMPRESSOR ADJUSTMENT

- ENGINE DISASSEMBLY AND REPAIR

- FUEL AND OIL FILTER ASSEMBLY

- FUEL FILTER ASSEMBLY

- FUEL PUMP INSTALLATION

- INJECTOR INSTALLATION

- LUBRICATING OIL PUMP

- OIL FILTER

- OIL PUMP AND GOVERNOR ASSEMBLY REMOVAL

- PISTON ASSEMBLY

- TECHNICAL DATA

- TIMING THE ENGINE

- VALVE ROCKER ADJUSTMENTS

- VALVE ROCKER GEAR INSTALLATION

- SPECIFICATIONS

- ENGINE SPECIFICATIONS (WISCONSIN)

- ENGINE SPECIFICATIONS (DEUTZ)

- ENGINE SPECIFICATIONS (PETTERS)

- MOTOR SPECIFICATIONS (ELECTRIC)

- TECHNICAL DATA

- ALPHABETICAL INDEX

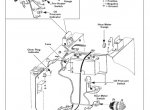

Screenshots for Bobcat 600, 600D, 610, 611 Skid Steer Loaders Service Manual PDF:

Our company provides for sale original spare part catalogs, workshop manuals, diagnostic software for all models of engines, cars, trucks, buses, forklifts, tractors, harvesters, cranes, buldozers, generators, construction and agricultural machines, motorcycles. To purchase a catalog online, please add the product to your cart, fill in the contact form online. Our managers proceed your order the same day.

Related products for Bobcat 600, 600D, 610, 611 Skid Steer Loaders Service Manual PDF:

Bobcat Parts Catalog 2004

All Bobcat production

65$

[08/2004]

|

Bobcat Telescopic Handlers Set of PDF Parts Manuals

PDF parts manuals contain parts and accessories information, detailed parts lists, illustrations and pictures for telescopic handlers Bobcat.

40$

[]

|

Bobcat S130 Skid Steer Loader Service Manual PDF

This tutorial includes step by step repair instructions, detailed diagrams and charts, safety rules, maintenance, specifications, engine service, system section.

50$

[2006. 2008, 2009 2013]

|

Bobcat Loaders

Spare parts catalog for Bobcat Loaders.

50$

[01/2005]

|